| Author |

Topic: Another 12 string |

Les Ford

From:

British Columbia, Canada

|

Posted 16 Oct 2024 4:00 pm

Posted 16 Oct 2024 4:00 pm |

|

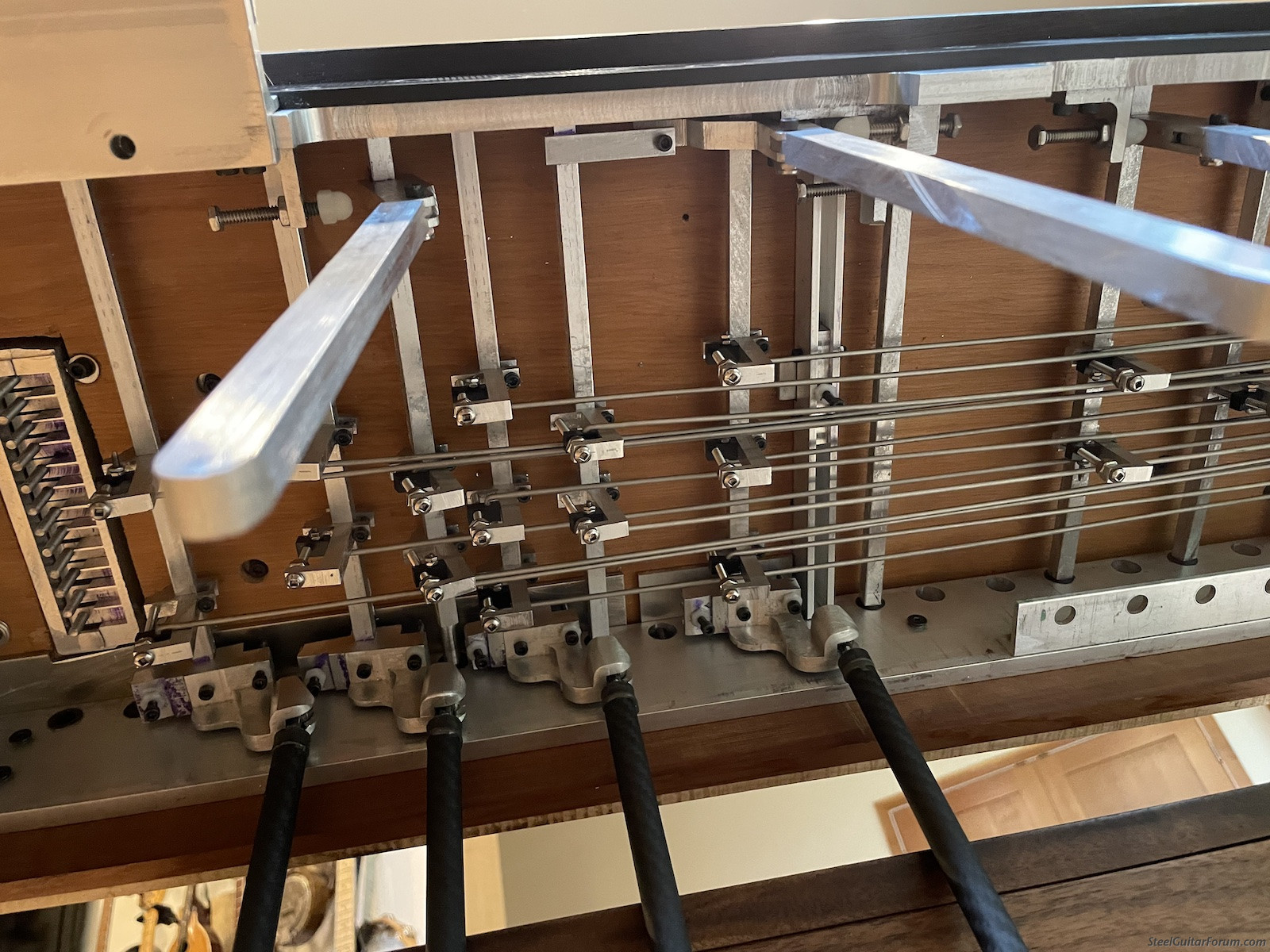

This one has sockets for a microphone boom stand. It also has 3/8 inch string spacing at the changer as well as at the nut.

|

|

|

|

Mike Preuss

From:

Mount Vernon, Washington, USA

|

Posted 16 Oct 2024 6:53 pm 12 string

Posted 16 Oct 2024 6:53 pm 12 string |

|

| Superb craftsmanship and very cool personal innovations! I like the floating neck and mic stand addition too. Any pics of the underside? |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 16 Oct 2024 8:31 pm

Posted 16 Oct 2024 8:31 pm |

|

Cool looking, Well laid out steel, Mike stand holes.

The double pickups are a nice addition.

What is the pedal rods made out of?

They give the guitar character.

Guitar to be proud of. BJ |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 16 Oct 2024 9:25 pm

Posted 16 Oct 2024 9:25 pm |

|

The floating fretboard and the carbon fibre rods are Ross Schaefer ideas. The rods have ball joints on the top and spin to adjust the pedal heights.

I'm still trying to figured a lot of it out but is working for me pretty well now.

Hopefully the next one will solve the remaining issues. Then I will probably revisit this one. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 18 Oct 2024 6:04 am

Posted 18 Oct 2024 6:04 am |

|

| That is some amazing work! Jaw on floor! Did you do the aluminum castings? |

|

|

|

Ross Shafer

From:

Petaluma, California

|

Posted 18 Oct 2024 10:35 am

Posted 18 Oct 2024 10:35 am |

|

| Nicely done! |

|

|

|

Ian Worley

From:

Sacramento, CA

|

Posted 18 Oct 2024 11:21 am

Posted 18 Oct 2024 11:21 am |

|

She's a beauty. Can we see the underside?

_________________

All lies and jest, still a man hears what he wants to hear and disregards the rest - Paul Simon |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 18 Oct 2024 1:19 pm

Posted 18 Oct 2024 1:19 pm |

|

There are no castings in this guitar Tim. Everything is milled out of 6061 aluminum on my hobby mill, table saw and band saw.

The pedal rod receivers are a bit clumsy with the adjustment screw being right above the ball end socket. I'm going to change this the next time to solve this and I'm going to mill the part out of Delrin to quiet the mechanism down.

This will give me an opportunity to remake the side rails with better cross shaft spacing.

This little shelf is handy for pedals or coffee and screws on and off with a single knob.The slot fits tight over the bottom of the rear rail and butts up against the carbon fiber rear stiffener.

This flag is easy to adjust. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 19 Oct 2024 5:43 am

Posted 19 Oct 2024 5:43 am |

|

| Les Ford wrote: |

There are no castings in this guitar Tim. Everything is milled out of 6061 aluminum on my hobby mill, table saw and band saw.

|

I need to rethink what my little mill is capable of! I should probably try to upgrade my cutters and fit some kind of DRO to my little mill. Or maybe just upgrade my machine. Then I could maybe stop doing a machinists work like a woodworker.

I really like the groove for the bar. I think that is the most practical innovation. I get so tired of trying to find a safe place to set it down, and more than a few times it has gone tumbling.

What about the endplates? Are those machined or formed? I had an idea to try and form some similar to that on the hydraulic press I have, but haven't gotten around to trying it. I suppose this could be machined if one had the appropriate radius cutters. It would require quite a lot of metal removal, but I could get a more complex profile this way.

Very inspiring work you have done on this guitar. |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 20 Oct 2024 6:12 am

Posted 20 Oct 2024 6:12 am |

|

Tim, The end plates are milled as well.

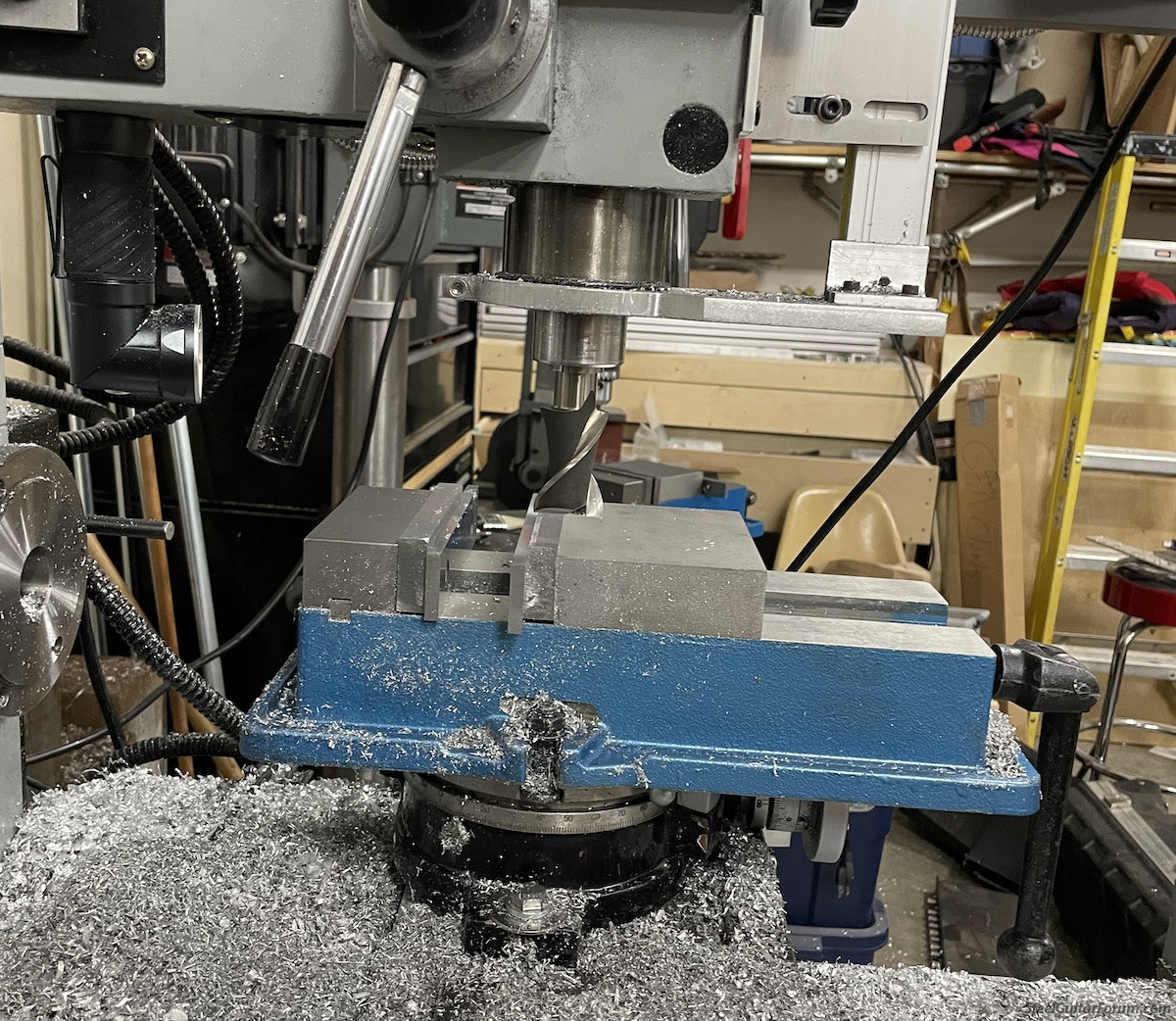

The critical thing for me is having a large enough mill vise to hold the metal. I have a six inch jaw opening so I can just get in the changer plate for milling. The end plates are 4 inches deep so that's easy to grab but I only have 7 or 8 inches of travel so I have to cut the inset for the top of the guitar in two passes. The end result is good enough for me but certainly not to the standard of, for example, a Sierra.

Here is the mill I use:

https://www.kingcanada.com/en/products/metalworking/metal-lathes/kc-1620clm-16-x-20-combo-lathemill

My favourite change for this guitar is the 3/8 inch string spacing. It is tuned to Maurice Anderson's C6 tuning.

I am currently rejigging the last 25 inch scale guitar I did to drop it to G6. This would give me bass on the bottom and a high seven and nine on the top. if I can still pull the changes on that guitar I'll go up to 25 1/2 inch scale for the next one. |

|

|

|

Ross Shafer

From:

Petaluma, California

|

Posted 20 Oct 2024 7:09 am

Posted 20 Oct 2024 7:09 am |

|

[quote="Les Ford"] "The end result is good enough for me but certainly not to the standard of, for example, a Sierra."

Don't sell yourself short Les, this all looks mighty fine to me. I have the advantage of way fancier tooling and machinery....doesn't meant the end result is any better though. Its the human not the machine!

Most mill vises allow moving the jaws to the outside of the vise to open up the vise's capacity. Looking closely at the picture of your machine, it appears that the vise also serves as the lathe tool post, can't tell for sure if the jaws can be moved or not.

I recently machined a big chunk of steel for a Tim Marcus project (gonna be super cool!) on my Bridgeport. The vise has about a 7" opening, moving the jaws allowed me to hold a 13" piece with plenty of room to go bigger.

Again great work and well done! You've definitely spent some time studying the Sierras I make. They say "imitation is the greatest form of flattery"...I'm flattered, thank you! |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 20 Oct 2024 8:56 am

Posted 20 Oct 2024 8:56 am |

|

Hey Ross, I have watched all of the "Making Chips" videos, listened to your interview on Brian Daste's podcast, and have looked at the pictures that I could find of your guitars, but I have never seen on up close and personal.

Your designs just make sense to me, except of course for the changer, because I have no idea what's going on in there. It just has to be better than the scissor finger setup though, which is just a collection of opposing forces arguing over who gets to pull the guitar out of tune first.

My goal is to make a decent guitar for upstairs, one for downstairs and one in the case for the gig and your videos have helped me immensely toward this.

I just tried your outside jaw trick and it doubled my vise opening! Thank you!

Last edited by Les Ford on 20 Oct 2024 9:28 am; edited 1 time in total |

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 20 Oct 2024 9:24 am

Posted 20 Oct 2024 9:24 am |

|

I'm just really impressed, Les. I was holding off on commenting because as a friend of Ross's and as the owner of a recent Sierra, I didn't know how Ross would respond to your use of the inspirations you drew from his designs. I apologize to Ross for not just assuming he would compliment your work and be flattered.

Yes, the ideas are brilliant and work really well.

Good going! |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 20 Oct 2024 9:53 am

Posted 20 Oct 2024 9:53 am |

|

Jon, I think Ross is being very gracious to a retired guy building himself guitars in his hobby shop. I would not dream of trying to compete with Ross or of selling these guitars as my own design. I'd be the first to say that the cheapest and best way to get a Sierra is not to buy the machinery and make it yourself but to buy one, done right, from Ross.

I'm just really grateful that a guy designing and working on that level is giving tips to a beginner like me. His tip to turn the jaws around on my vice was like giving me a new mill!

Tim, here is my setup:

I use the rotating table as a spacer to get closer to the cutter and to cut angles. It also makes it easier to adjust the tramming. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 20 Oct 2024 11:09 am

Posted 20 Oct 2024 11:09 am |

|

| Les Ford wrote: |

Tim, here is my setup:

I use the rotating table as a spacer to get closer to the cutter and to cut angles. It also makes it easier to adjust the tramming. |

That is a respectable end mill and pile off chip ! Those combo machines are cool. A bit of a compromise, but for the weekend machinist, more than enough obviously. I have been itching to buy the Grizzly combo 12" jointer planer. A compromise, but I would love to get rid of 2 of my machines for 1 that weighs less than 1/4 of just my planer. At some point I will be moving into a new space and upgrading some of my machinery and something like that may make more sense. Till then I am gonna try to fit some cheap DROs to my old mill drill. It will certainly be better than using a ruler!

Thanks for the response. I am learning I think.... I hope! |

|

|

|

Les Ford

From:

British Columbia, Canada

|

|

|

|

Joe Bill Moad

From:

Oklahoma

|

Posted 20 Oct 2024 1:05 pm Great Homebuilt Universal Guitar!

Posted 20 Oct 2024 1:05 pm Great Homebuilt Universal Guitar! |

|

What a great looking Universal home built Guitar! Great Skill involved in that build! Enjoy it to its fullest!

Ross is an excellent builder and Human Being! He is not worried of competition,”He is the Competition.” All brands being built today will upgrade engineering or be lost in the fog. The Sierra is the most highly thought out machine both playability, Sound, and ease of operational parts. Someday in another phase of my playing I hope to own a Sierra. Just don’t know when.

Respectfully

Joe Bill Moad

_________________

Don’t Worry About The Mule! Load The Wagon! |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 11 Nov 2024 8:08 am

Posted 11 Nov 2024 8:08 am |

|

some amazing woodwork and machining!

How's that Neck Pickup acting?

Thanks!... J-D.

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 12 Nov 2024 4:12 pm

Posted 12 Nov 2024 4:12 pm |

|

| J D Sauser wrote: |

some amazing woodwork and machining!

How's that Neck Pickup acting?

Thanks!... J-D. |

Hey JD,

I mainly use the neck pickup, so it is working pretty well but I might swap it out for a 12 string Stringmaster style pickup that a buddy made for me.

I'm thinking to try to mill the changer/pickup assembly to support a plastic pickguard so that I can try different pickup combinations because I want to get away from these super high output steel guitar pickups. |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 13 Nov 2024 6:48 pm

Posted 13 Nov 2024 6:48 pm |

|

| Les Ford wrote: |

| J D Sauser wrote: |

some amazing woodwork and machining!

How's that Neck Pickup acting?

Thanks!... J-D. |

Hey JD,

I mainly use the neck pickup, so it is working pretty well but I might swap it out for a 12 string Stringmaster style pickup that a buddy made for me.

I'm thinking to try to mill the changer/pickup assembly to support a plastic pickguard so that I can try different pickup combinations because I want to get away from these super high output steel guitar pickups. |

What I was wondering Les, is what it sounds like (the “neck” pos. pickup).

I have been wanting to add a neck-pickup to my guitars for a long time to “warm”- up the tone.

Thanks!… JD.

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 14 Nov 2024 10:14 pm

Posted 14 Nov 2024 10:14 pm |

|

[quote="J D Sauser"][quote="Les Ford"]

| J D Sauser wrote: |

What I was wondering Les, is what it sounds like (the “neck” pos. pickup).

I have been wanting to add a neck-pickup to my guitars for a long time to “warm”- up the tone.

Thanks!… JD. |

It does exactly what you would expect. It has the warmer tone typical of a neck pickup.

Some people like a thinner sound but for me the neck pickup is better no matter what type of pickup it is. |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 15 Nov 2024 10:28 am

Posted 15 Nov 2024 10:28 am |

|

[quote="Les Ford"][quote="J D Sauser"]

| Les Ford wrote: |

| J D Sauser wrote: |

What I was wondering Les, is what it sounds like (the “neck” pos. pickup).

I have been wanting to add a neck-pickup to my guitars for a long time to “warm”- up the tone.

Thanks!… JD. |

It does exactly what you would expect. It has the warmer tone typical of a neck pickup.

Some people like a thinner sound but for me the neck pickup is better no matter what type of pickup it is. |

Thanks for confirming that it does what it's supposed to do.

I am studying how to get the thin string only to warm up with a neck pickup only under these. I like "clear" bass strings but warm high strings without deadening the bass strings.

And I should maybe specify that I am thinking C6th or Universal, where string gauges can range from o.o11 thru o.o70 all using the same scale length. It's a challenge.

I would like to have 4 pickups, under string 1-5 or 1-6 and another under string 6-10 or 7-12 respectively (10 or 12 string) on both the bridge and neck position and being able to balance them all previous to bundling the signal sent off to the amp.

I am currently modifying changer on several guitar with the same goal of "pre-EQing" the sound ACROSS the strings, using different shapes and materials on the changer fingers, and it's been a big step forward to that goal.

I like to pick at or right of the 24th fret on C6th for pick-to-string response and also a more constant tone, on E9th I would probably even be more over the 26th fret. But that with the bridge pickup only, brings about a nasal sound we often have tried to "thicken" by adding "bottom" via boosting the low end on way too powerful amps.

Your guitar has evidently many "Ross Shafer gen. SIERRA"-elements which are worth while considering since the company has again led the way in new ideas being incorporated. Very well built, beautiful metal and wood work, which is a rarely found combination on one-off's. So my hat to you!

One more question. I just got me a mini-mill and am looking for good end-mills for aluminum. I see your end-mill bit looks quite unique. IF that one seems to do uniquely well cutting aluminum as it looks, would you mind sharing what brand it is (where to get it), because that Chinese-Amazon junk is sucking the daylight out of my nervous system.

Thanks!... J-D.

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 15 Nov 2024 4:33 pm

Posted 15 Nov 2024 4:33 pm |

|

Hey JD,

I've worked out that you want to avoid any kind of coating on your end mills and to get the ones with only two flutes. Coatings and extra flutes seem to gum up with the aluminum.

I only buy American or Canadian made end mills if I possibly can with the exception of round over mills, which are ungodly expensive, so I get those from Accusize, which I think is a Canadian reseller of Asian tooling. I like the Niagara Cutter brand, but anything made in North America tends to be higher quality and lasts longer before sharpening.

You can save a lot of money by looking around on Craigslist for used American tooling.I have bought bags of end mills and lathe tooling from retired machinists. I bought all my lathe tooling for five bucks each from one fellow who also had some cool custom made cutters that he had made himself. You can literally by them this way cheaper than you can sharpen them, and they tend to be good quality cutters.

That big cutter in the photo I posted is one of these: https://www.amazon.ca/dp/B00GWQ55I8?ref=ppx_yo2ov_dt_b_fed_asin_title

I got it for a specific job in making some new end plates but it has turned out to be generally useful.

I'm dealing with some of the same issues as you. I am experimenting with a 12 string guitar tuned down to A6 with a Bb on the bottom and I am having to use Bass VI strings on the bottom couple of strings to try to get them to not be too rubbery. I'm going to try a 13 or 14 string guitar next and break out the bottom strings from separate pickups to a separate output and into a separate pre-amplifier and separate sides of a stereo Seymour Duncan Powerstage. This way I can have not have delay and reverb muddying up the bass. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 16 Nov 2024 5:53 am

Posted 16 Nov 2024 5:53 am |

|

| Les Ford wrote: |

Hey JD,

I've worked out that you want to avoid any kind of coating on your end mills and to get the ones with only two flutes. Coatings and extra flutes seem to gum up with the aluminum.

|

That confirms what I have been experiencing. Don't laugh, but router bits actually work pretty well, and can be sharpened pretty easily with a fine diamond stone. Smaller router bits under 1/2" not so good though. I think my machine doesn't spin fast enough for these. |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 18 Nov 2024 10:08 am

Posted 18 Nov 2024 10:08 am |

|

| Les Ford wrote: |

Hey JD,

I've worked out that you want to avoid any kind of coating on your end mills and to get the ones with only two flutes. Coatings and extra flutes seem to gum up with the aluminum.

I only buy American or Canadian made end mills if I possibly can with the exception of round over mills, which are ungodly expensive, so I get those from Accusize, which I think is a Canadian reseller of Asian tooling. I like the Niagara Cutter brand, but anything made in North America tends to be higher quality and lasts longer before sharpening.

You can save a lot of money by looking around on Craigslist for used American tooling.I have bought bags of end mills and lathe tooling from retired machinists. I bought all my lathe tooling for five bucks each from one fellow who also had some cool custom made cutters that he had made himself. You can literally by them this way cheaper than you can sharpen them, and they tend to be good quality cutters.

That big cutter in the photo I posted is one of these: https://www.amazon.ca/dp/B00GWQ55I8?ref=ppx_yo2ov_dt_b_fed_asin_title

I got it for a specific job in making some new end plates but it has turned out to be generally useful.

I'm dealing with some of the same issues as you. I am experimenting with a 12 string guitar tuned down to A6 with a Bb on the bottom and I am having to use Bass VI strings on the bottom couple of strings to try to get them to not be too rubbery. I'm going to try a 13 or 14 string guitar next and break out the bottom strings from separate pickups to a separate output and into a separate pre-amplifier and separate sides of a stereo Seymour Duncan Powerstage. This way I can have not have delay and reverb muddying up the bass. |

Thanks Les.

YES, but it has become increasingly difficult to ID and even find US, Canadian or European made tools. Even screws are of disastrous quality... all made in China.

It's not that things are not manufactured in the US but, US manufacturers don't seem as "smart" at placing their products with selling platforms like Amazon, while the Chines use these like it's their market.

Thanks!... J-D.

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|