| Author |

Topic: Excel U12 Pedal Rods Rubbing Against Cabinet |

Alex Mak

From:

New York, USA

|

Posted 4 Feb 2025 1:28 pm

Posted 4 Feb 2025 1:28 pm |

|

Hi all,

Touring guitarist finally dipping my toes into the steel world! I got an older Excel U12 8x6 for a great deal, but it needs some TLC.

I reached out to Excel a bit ago, but haven't heard anything back yet.

There are black stickers on the pedal rods to indicate their order, but I'm not sure if the "highest" sticker should be on pedal 1 or 8.

The B and C rods are rubbing against the side of the cabinet when pressed, causing friction and wearing away the metal. The pedal rods also seem to be bending around this spot. Is there any way to prevent this?

I wasn't sure if this may be from having the pedal rack on the wrong legs, pictures attached. There are metal spacer rings on 2 of the legs, but I wasn't sure their purpose.

There are a few other things I'm trying to fix, but sorting these out first should be enough to get things up and running. Any help or info on this steel is much appreciated, thanks in advance!

Imgur link with pics: https://imgur.com/a/excel-u12-GNJENMP |

|

|

|

Mike Vallandigham

From:

Martinez, CA

|

Posted 4 Feb 2025 2:00 pm

Posted 4 Feb 2025 2:00 pm |

|

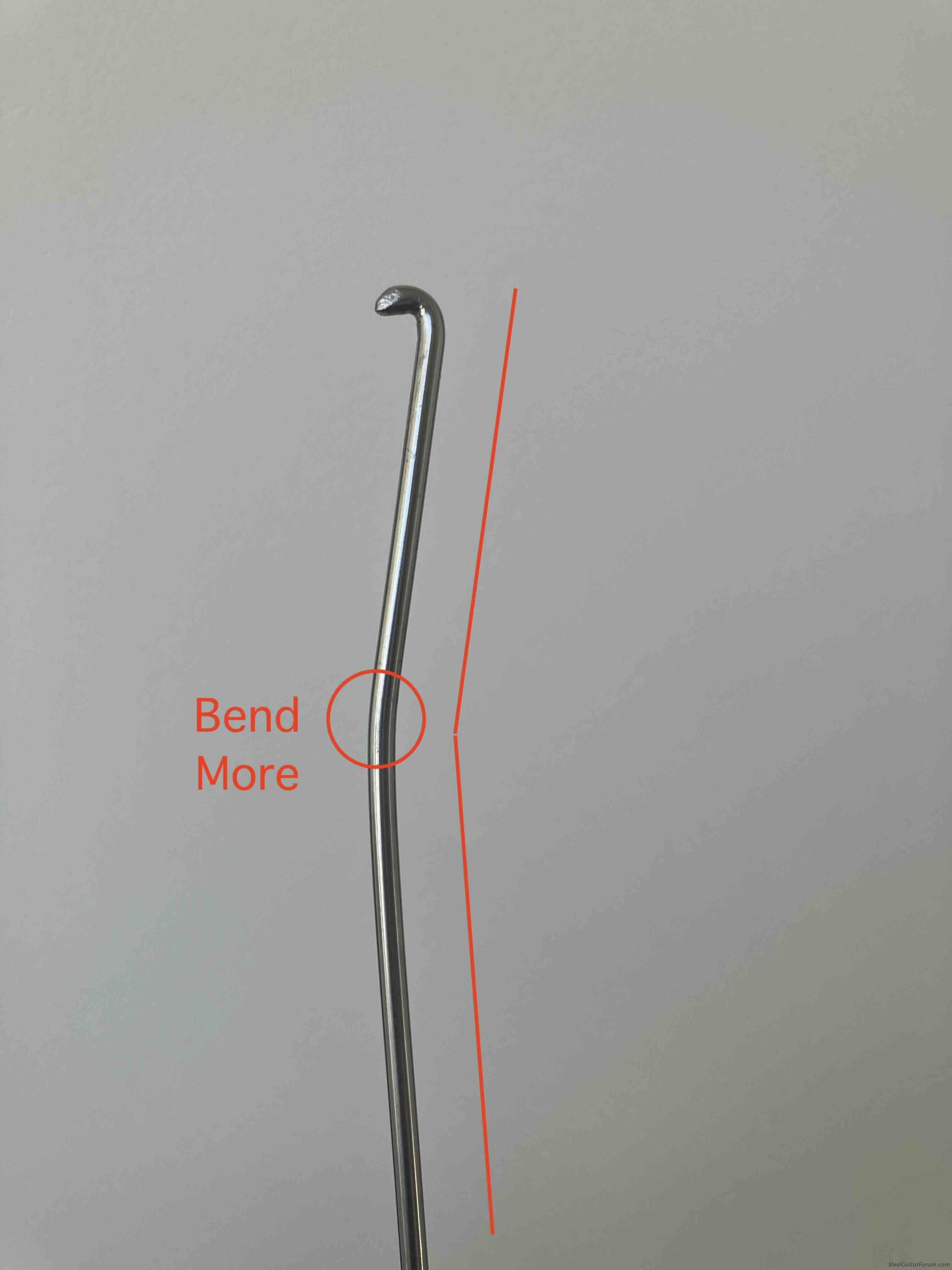

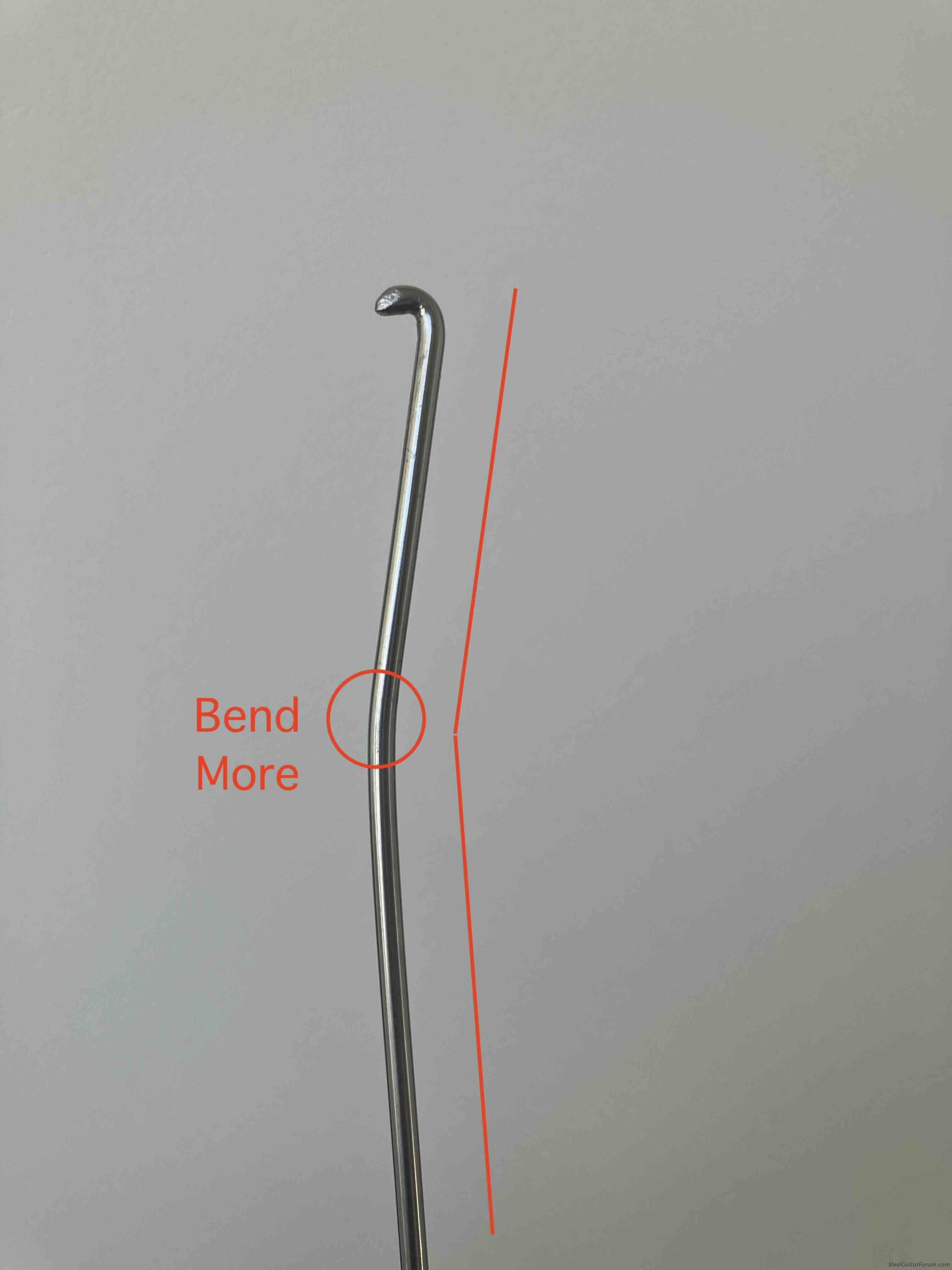

| The pedal rods are supposed to be bent a little - just after they clear the apron - to prevent rubbing. Maybe add a little more bend to them? |

|

|

|

David Munson

From:

St. Louis, Missouri, USA

|

Posted 4 Feb 2025 3:55 pm Put Velcrox pads on frame for rubbing

Posted 4 Feb 2025 3:55 pm Put Velcrox pads on frame for rubbing |

|

| Put adheasive Velcrox tape on frame for rubbing. |

|

|

|

David Munson

From:

St. Louis, Missouri, USA

|

Posted 4 Feb 2025 4:00 pm pedal 1 is on the left

Posted 4 Feb 2025 4:00 pm pedal 1 is on the left |

|

email me for more informaation.

Mine is newer. 2003 model |

|

|

|

Marvin Born

From:

Ohio, USA

|

Posted 4 Feb 2025 7:47 pm Excel

Posted 4 Feb 2025 7:47 pm Excel |

|

| Is it possible that the pedal rods are not factory? Those rings could be part of an height extension kit. Raising the guitar the height of those rings would require new pedal rods, or rod extensions. If they are after market, they may not be bent correctly. |

|

|

|

Toshiyuki Shoji

From:

Japan

|

Posted 4 Feb 2025 11:08 pm

Posted 4 Feb 2025 11:08 pm |

|

Hi Alex

You seem to be having trouble.

I am a former employee of Excel and last summer I went independent with my own company called SHOJI.

But now I am on leave from work while I am being treated for Guillain-Barre Syndrome.

Your instrument was made long before I started working with Excel.

Since I have not seen your instrument in person, I cannot solve all problems, but I will answer as best I can.

The sticker on the pedal rod was placed by the previous owner.

I would guess that the previous owner's intent is that the rod without the sticker was 8P, or that it was 4P but the sticker was removed.

You are free to leave these stickers on or remove them.

Regarding the pedal rod rubbing issue.

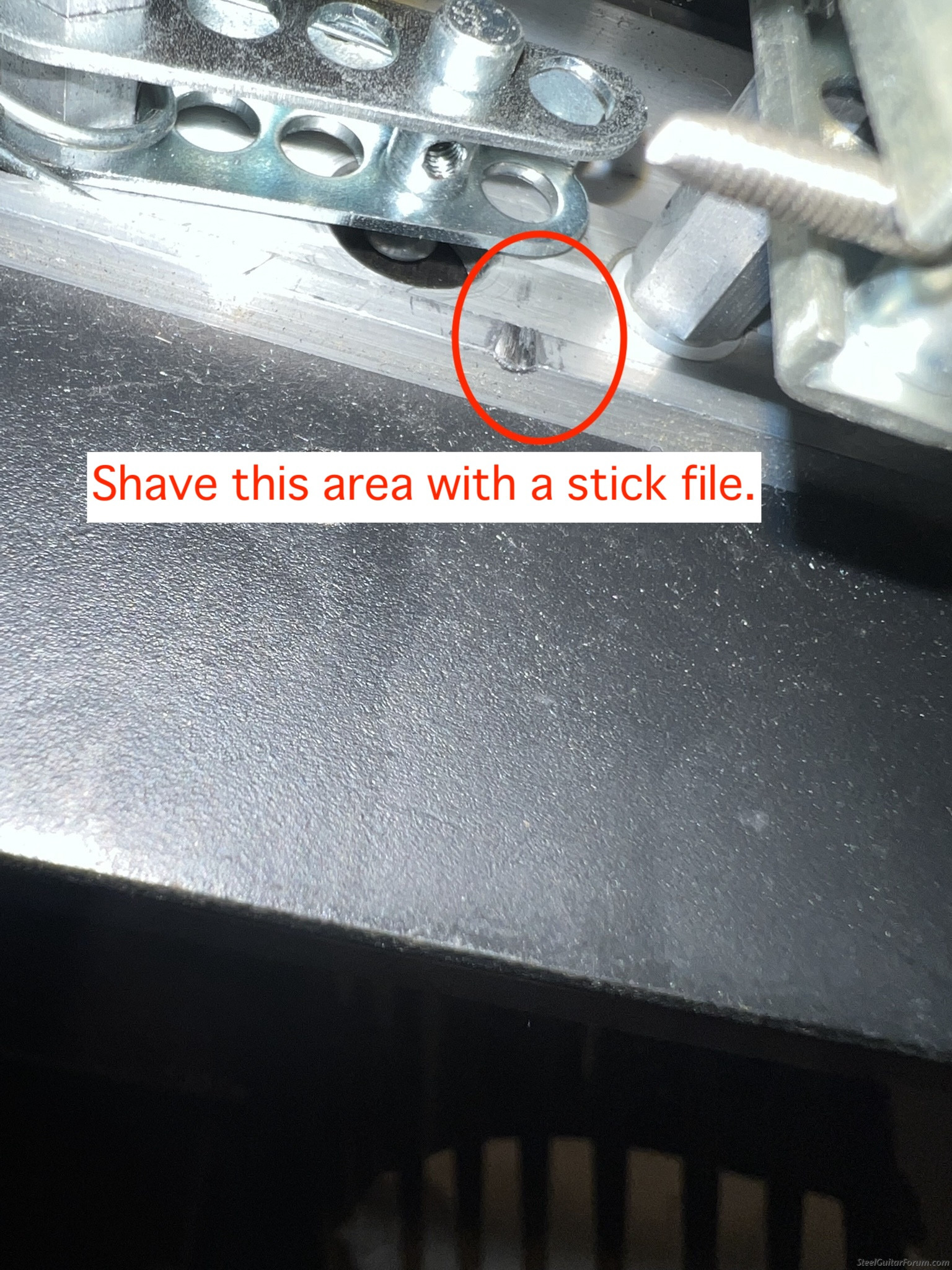

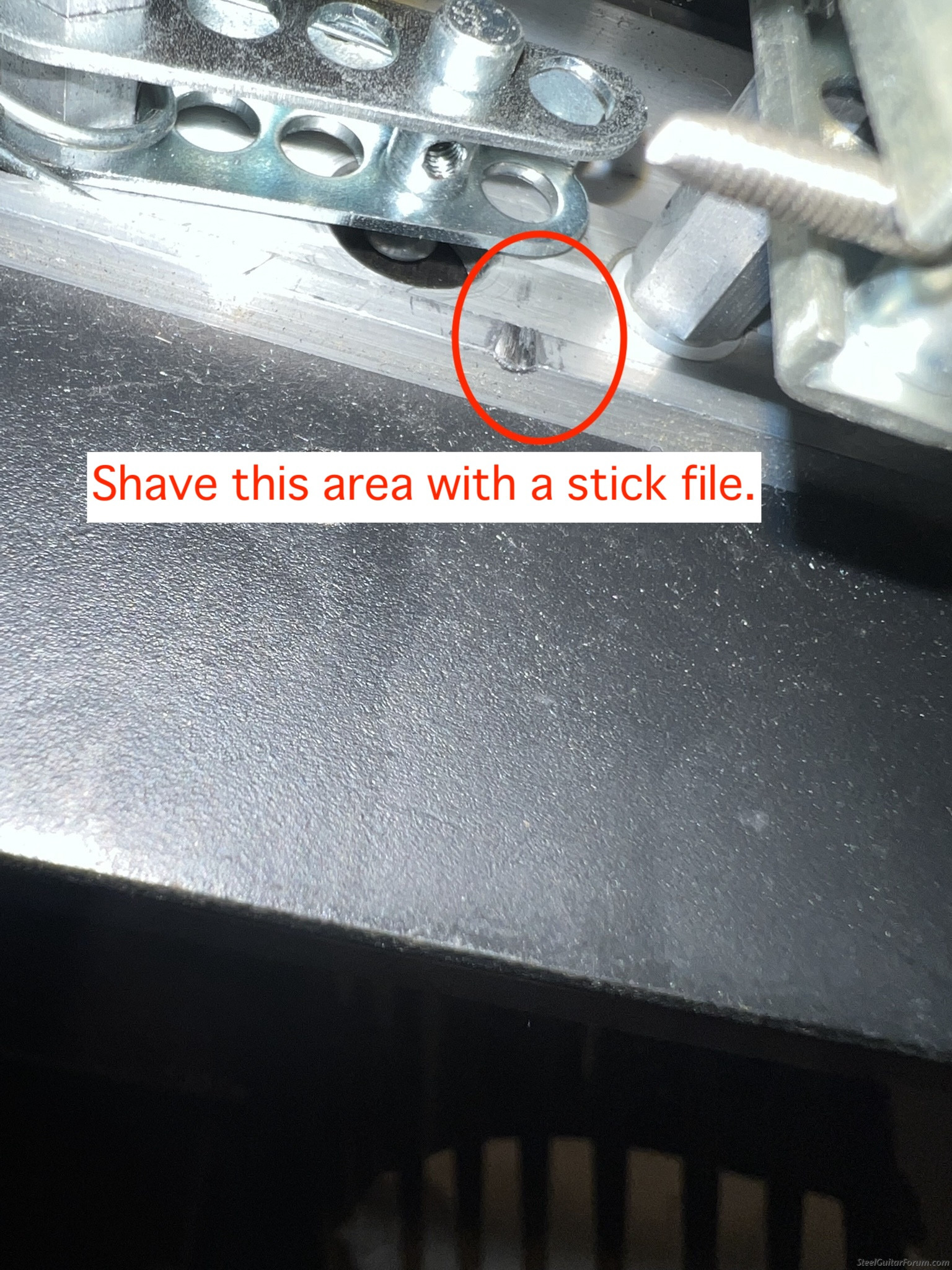

The solution is either to increase the bend of the pedal rod or to use a stick file to remove the rubbing area on the cabinet.

Regarding leg spacers.

The previous owner may have used legs with spacers for the front legs. The intention was to lengthen the legs of the steel guitar.

From the pictures it looks like there will be no half stops. I can't say for sure because I don't have detailed photos.

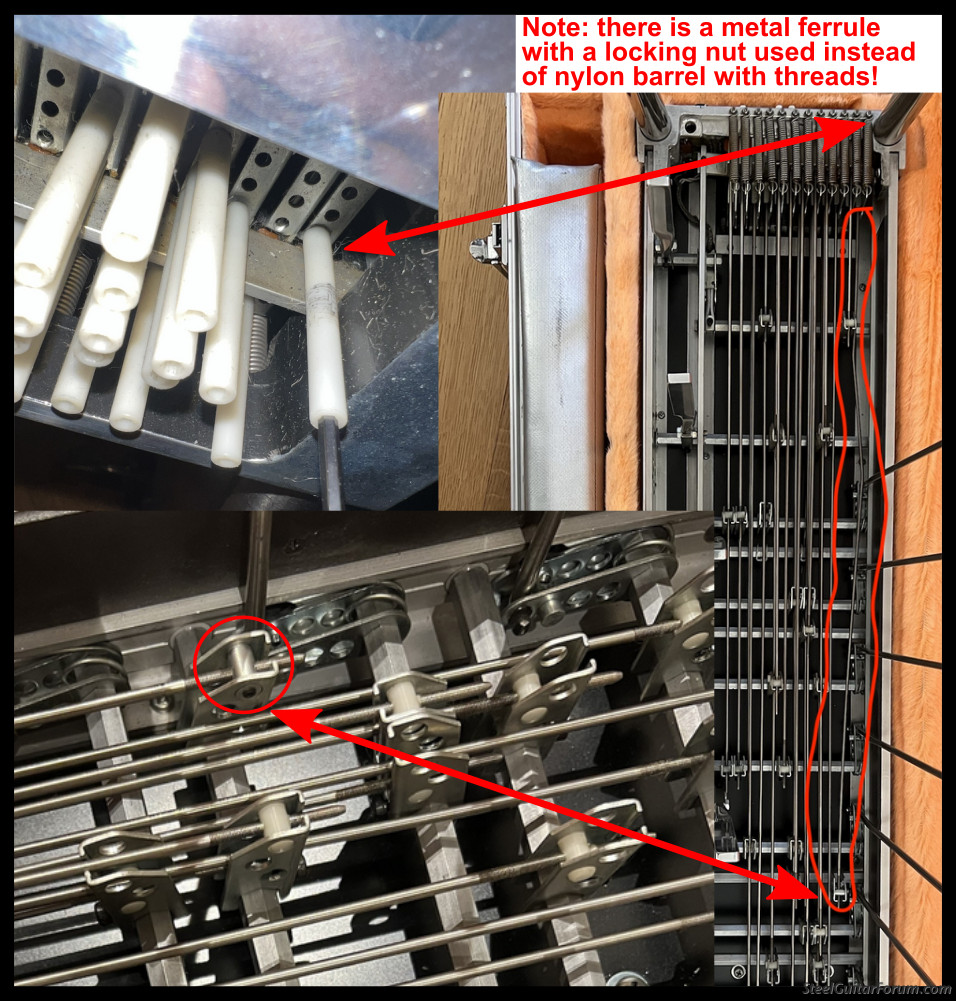

It is not pleasant from a mental health standpoint to have a changer rod (pull rod) that is too long.

Understandable.

I think it will work as is, if you are concerned, you could try removing the bent rod once and straightening it back out.

The fact that the tuning nut is difficult to turn.

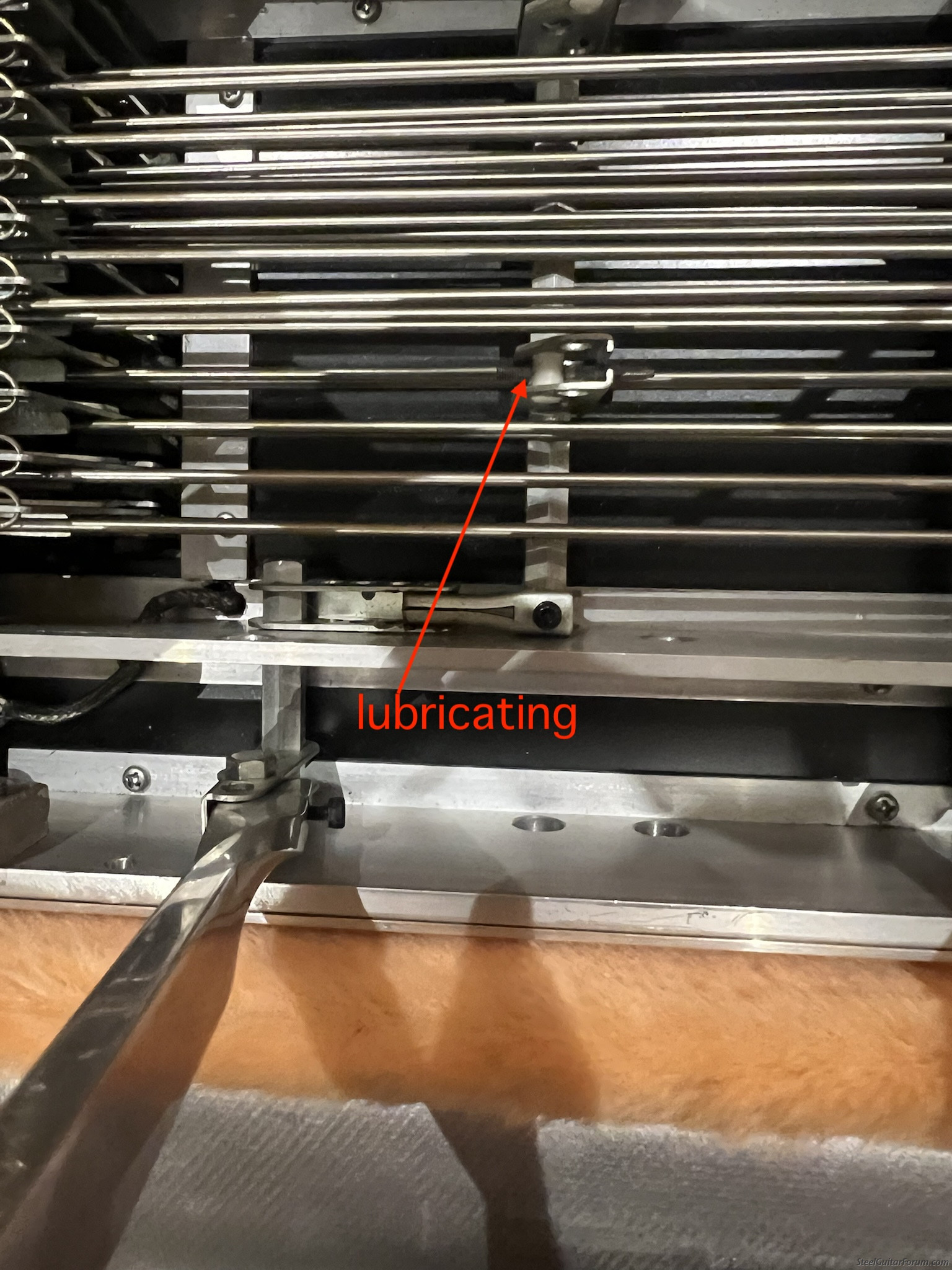

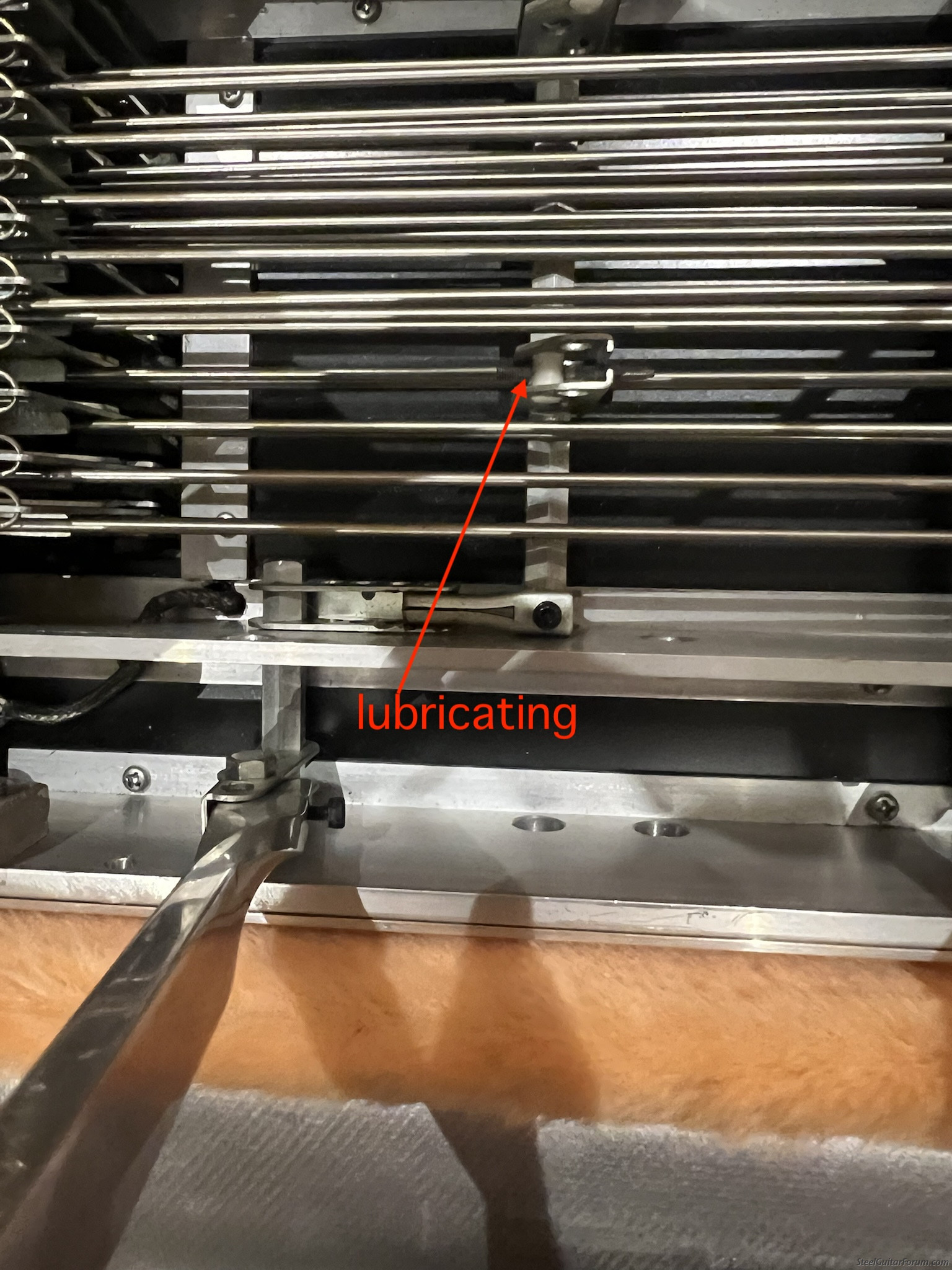

Try putting lubricant in the white plastic barrel, which contains the screw at the end of the pull rod.

|

|

|

|

Howard Palmer

From:

Colorado, USA

|

Posted 5 Feb 2025 5:58 pm

Posted 5 Feb 2025 5:58 pm |

|

Is Excel still in business and if so does anyone know the approximate cost of a

S12 universal? |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 5 Feb 2025 7:05 pm

Posted 5 Feb 2025 7:05 pm |

|

It would be better to bend the rod, Than to start filing on the apron of the guitar. Rods are cheaper than guitar bodies.

The pedal rods may have been replaced, If someone raised or lowered the guitar. And who ever replaced them did not put the required bend in the rods. To clear the front apron.

Good Luck getting the problem solved. |

|

|

|

Alex Mak

From:

New York, USA

|

Posted 5 Feb 2025 7:06 pm

Posted 5 Feb 2025 7:06 pm |

|

| Toshiyuki Shoji wrote: |

Hi Alex

You seem to be having trouble.

I am a former employee of Excel and last summer I went independent with my own company called SHOJI.

But now I am on leave from work while I am being treated for Guillain-Barre Syndrome.

Your instrument was made long before I started working with Excel.

Since I have not seen your instrument in person, I cannot solve all problems, but I will answer as best I can.

The sticker on the pedal rod was placed by the previous owner.

I would guess that the previous owner's intent is that the rod without the sticker was 8P, or that it was 4P but the sticker was removed.

You are free to leave these stickers on or remove them.

Regarding the pedal rod rubbing issue.

The solution is either to increase the bend of the pedal rod or to use a stick file to remove the rubbing area on the cabinet.

Regarding leg spacers.

The previous owner may have used legs with spacers for the front legs. The intention was to lengthen the legs of the steel guitar.

From the pictures it looks like there will be no half stops. I can't say for sure because I don't have detailed photos.

It is not pleasant from a mental health standpoint to have a changer rod (pull rod) that is too long.

Understandable.

I think it will work as is, if you are concerned, you could try removing the bent rod once and straightening it back out.

The fact that the tuning nut is difficult to turn.

Try putting lubricant in the white plastic barrel, which contains the screw at the end of the pull rod.

|

Toshiyuki-san, thank you very much for taking the time to help, it is much appreciated! I hope you are in better health soon.

I will try bending the rods. |

|

|

|

Alex Mak

From:

New York, USA

|

Posted 5 Feb 2025 7:16 pm Re: pedal 1 is on the left

Posted 5 Feb 2025 7:16 pm Re: pedal 1 is on the left |

|

| David Munson wrote: |

email me for more informaation.

Mine is newer. 2003 model |

Emailed! |

|

|

|

Toshiyuki Shoji

From:

Japan

|

Posted 5 Feb 2025 11:15 pm

Posted 5 Feb 2025 11:15 pm |

|

| You're welcome! Feel free to ask if you have any trouble. |

|

|

|

Oliver Samland

From:

Hamburg, Germany

|

Posted 9 Feb 2025 2:41 pm

Posted 9 Feb 2025 2:41 pm |

|

Hi Alex,

a couple of the issues you mentioned in your pictures are related. That long crooked rod (raising string 1 with your left knee right lever) is LOCKED on the bell crank with a ferrule utilizing a locking nut. On Excels of that era, the tuning nuts are firmly connected to the pull rods. The pull rods have threads on the bell crank end. In the bell crank there are little nylon barrels with a threaded hole for the pull rod. As you need to spin the whole pull rod to tune a change, you can't have bend pull rods like on most others steels. As the locked pull rod in the pic has threads, I presume it is the original rod with the permanent connected tuning nut. That's why you can't turn the nylon tuner, and maybe it's the reason the rod is crooked and bend because someone tried anyway...

****

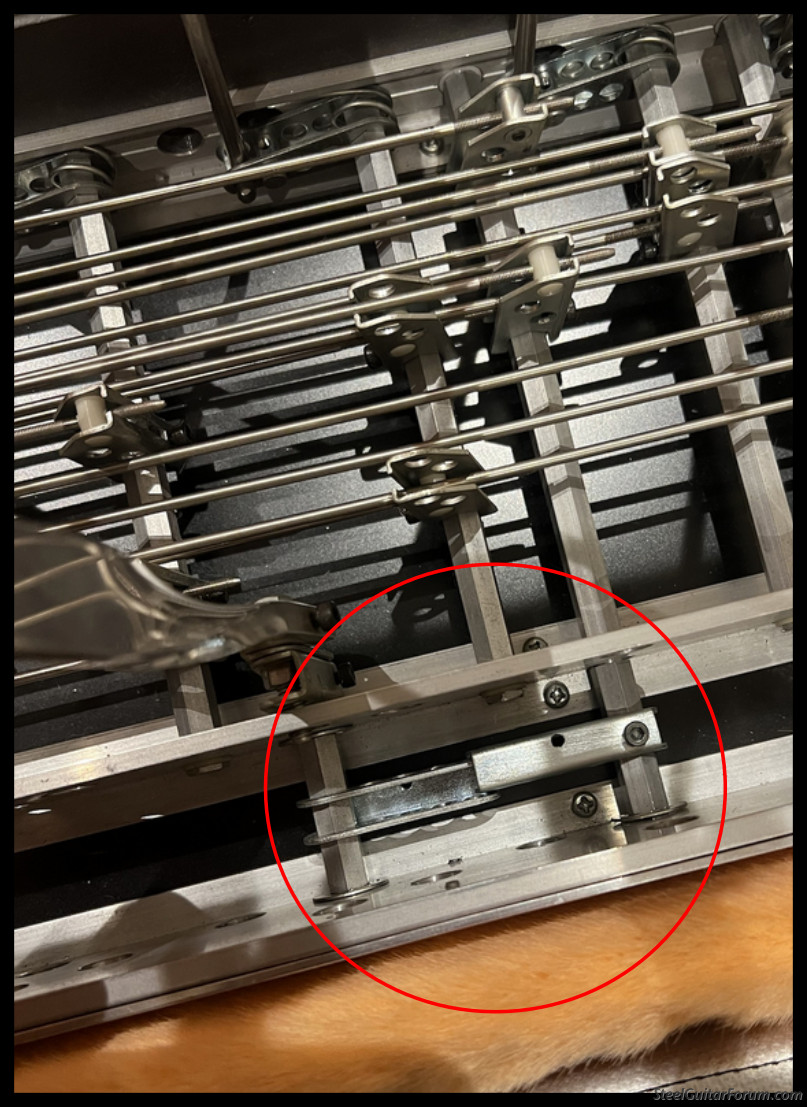

What you have there is a reverse mechanism (not a half stop). It inverts the direction in which the cross rod turns and allows the bell crank to pull the rod. Knee levers going to the >>> right need those (on all pull guitars, that is).

On my Excel, which is of similar vintage as your's, there is a little rod as a link in between those cranks, connected with metal ferrules and locking nuts. By changing the lenght of the linkage, it's possible to fine tune the knee lever action.

(Just speculating here: there are little holes drilled in the cranks in your reverse mechanism. Possibly there was a linkage rod originally implemented in your guitar, and some former owner took it out to use the ferrule on the long bend rod I mentioned above, who knows)

****

You can check if the little allen head screw that holds the pedal rod bell crank on the cross rod became loose and thus the pedal rod bell crank somehow got too near to the front apron causing friction. If that's the case, try if you can slide that pull rod bell crank a tiny bit to the center of the guitar, just enough it doesn't rub against the cabinet anymore. The screw is a pain to reach unless you dissasemble half the steel guitar, maybe it's possible with the right needle nose pliers.

****

I have the 10 string sibbling of your Excel, in fact yours is the closest to mine I've seen yet.

Mine is an absolute joy to play, sounds fantastic and it's light as a (heavy) feather.

You have a great steel there!

Ollie |

|

|

|