| Author |

Topic: MSA VIntage XL - Good for a D13 newbie ? |

Paul Mageau

From:

Maine, USA

|

Posted 11 Sep 2024 10:49 am

Posted 11 Sep 2024 10:49 am |

|

Hi

I found a MSA Vintage XL S12 for $1800. It looks in decent shape but I wonder if it's worth the money and a good starter guitar for a newbie to pedal steel who also wants to learn D13 tuning. (I know it needs at least one more pedal for D13)

I also am wondering if it would have any resale interest should I decide to upgrade?

Thanks!

Paul

|

|

|

|

Jared Ruari

From:

Oregon, USA

|

Posted 12 Sep 2024 8:51 am

Posted 12 Sep 2024 8:51 am |

|

What sort of changer does it have? D13th is easiest with a 3 up and 3 down changer.

If it has a capable changer, then getting a s12 for under 2k and then having it tuned up and converted seems to be the most cost effective way to get into a D13th setup. |

|

|

|

Paul Mageau

From:

Maine, USA

|

Posted 12 Sep 2024 9:46 am

Posted 12 Sep 2024 9:46 am |

|

| That's a great question! I hadn't thought of that. I'll look into that. I think it's a 3u/3d but not sure. Thanks! |

|

|

|

Lee Rider

From:

Fort Bragg, California, USA

|

Posted 12 Sep 2024 11:25 am

Posted 12 Sep 2024 11:25 am |

|

If it is not 3 up/down I believe that Tom Bradshaw makes a part that add the pull. He did it on an S-12 that I had to make it a Universal.

_________________

Bowman SD10 push pull 3x5, Modified Hudson PedalBro, Sarno Tonic preamp, Evans FET 500. with Altec 418B, Standel Custom 15, '67 Showman with D-130F in cabinet, Ganz Straight Ahead, custom Wolfe 6 string dobro, '52 Gibson Century 6. |

|

|

|

Paul Mageau

From:

Maine, USA

|

Posted 12 Sep 2024 12:25 pm

Posted 12 Sep 2024 12:25 pm |

|

| Thanks Lee! At the risk of sound dumb, who is Tom Bradshaw ? |

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 12 Sep 2024 12:34 pm

Posted 12 Sep 2024 12:34 pm |

|

https://steelguitarbradshaw.com/

I asked Tom about that gizmo a few years ago and he said he hadn't made them in a long time and that they were a pain to make and he basically wasn't interested in tooling up to make me one.

I totally understand.

|

|

|

|

Paul Mageau

From:

Maine, USA

|

Posted 12 Sep 2024 12:46 pm

Posted 12 Sep 2024 12:46 pm |

|

| Clever idea, thanks Jon! I bet I could 3D design one if needed and use carbon fiber printed plastics. Fun project ! |

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 12 Sep 2024 12:49 pm

Posted 12 Sep 2024 12:49 pm |

|

| I bet you could! I'm so behind the curve and I have no idea what sort of object is...and is not...a good candidate for 3D printing. |

|

|

|

Jamie Howze

From:

Boise, ID

|

Posted 13 Sep 2024 9:52 am

Posted 13 Sep 2024 9:52 am |

|

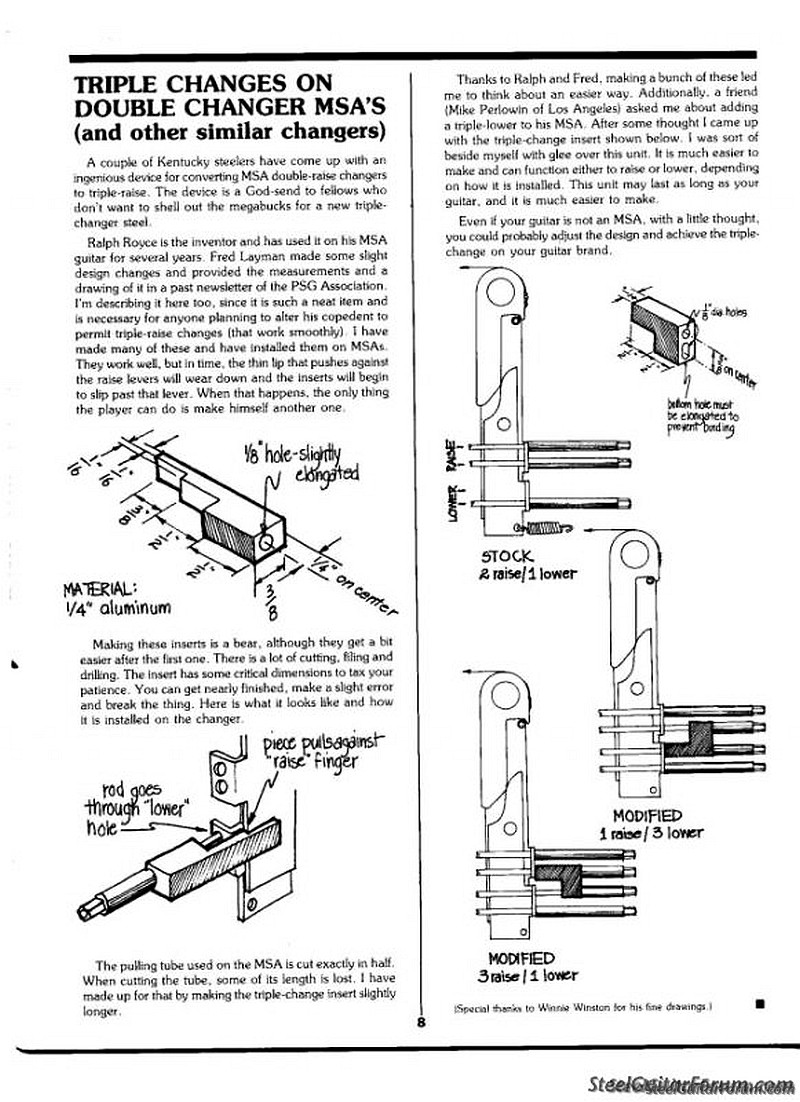

I made a couple of these Bradshaw adapters when I converted my GFI Ultra U12. I made the first when I setup the Newman E9/B6 and another when I moved to D13. I used two to get the lowers on the 10th and 11th strings.

I made them from aluminum bar stock using a hacksaw, file and drill press. They work like a charm! I bet 3D printing would work great too, although, the abrasion from the rods may be a long-term problem. I made the simpler "L" shaped version and took liberties with some of the measurements to make it fit the GFI changer. While the 7x5 setup on the GFI isn't as complete as Johny's version it certainly can do anything I'll ever be capable of.

This is the first one I made. The second one turned out a bit neater, but I don't have any pix of it. They ain't pretty, but they work:

Last edited by Jamie Howze on 13 Sep 2024 1:46 pm; edited 1 time in total |

|

|

|

Paul Mageau

From:

Maine, USA

|

Posted 13 Sep 2024 10:21 am

Posted 13 Sep 2024 10:21 am |

|

| Nice work, Jamie. With the proper engineering grade filament like some form of carbon or glass reinforced nylon or polypropylene material these should wear pretty well. The good news is printing another when the part needs replacing is trivial! |

|

|

|

Wayne Brown

From:

Bassano, Alberta, Canada

|

Posted 13 Sep 2024 12:05 pm steel guitar parts

Posted 13 Sep 2024 12:05 pm steel guitar parts |

|

I think we may still have a couple of the Tom Bradshaw ones we got from Al Brisco but there not listed on our site. I would have to check stock.

thanks

wayne

_________________

Owner Out West Music,Seats,Parts and accessories

www.outwestcountry.ca |

|

|

|

Jamie Howze

From:

Boise, ID

|

Posted 13 Sep 2024 1:49 pm

Posted 13 Sep 2024 1:49 pm |

|

| Thanks Paul. You're right printed ones could be easily replaced. A smidge lighter too. |

|

|

|

Joe Bill Moad

From:

Oklahoma

|

Posted 13 Sep 2024 2:35 pm

Posted 13 Sep 2024 2:35 pm |

|

I have a guy in Iowa that is a genius at this kind of fabrication. If someone could get me a copy of all hard parts needed in building or restoring these fabulous instruments I could get them to him and they would be spot on. Need to know bar stock sizes(aluminum) and all the nuts and bolts needed to build these. He has a large cad system and can build anything metal or aluminum, or any metal that would be needed.

Thanks

Jbm

_________________

Don’t Worry About The Mule! Load The Wagon! |

|

|

|