| Author |

Topic: Homemade bender? |

Mike McBride

From:

Indiana

|

Posted 30 Jan 2022 1:34 pm

Posted 30 Jan 2022 1:34 pm |

|

I'm considering making a homemade b bender for my $50 lap steel. Anyone done this? I may use something like this:

|

|

|

|

Dom Franco

From:

Beaverton, OR, 97007

|

|

|

|

David Venzke

From:

SE Michigan, USA

|

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 31 Jan 2022 6:59 am

Posted 31 Jan 2022 6:59 am |

|

I have been thinking about something similar. Look at a single finger pull release changer on a pedal steel as if they were reversed and extended backwards like levers over the strings. The string would go under the lever and as its pushed down it would pull the string raising the pitch. This could possibly be rigged to do a lower as well in reverse. The difficulty I was having in the design is making it ergonomic and where to put the tuning stop. Sorry if this doesn't make sense. I would love to see what you come up with.

https://reverb.com/item/651944-vintage-bigsby-palm-pedal-for-1969-tele |

|

|

|

Mike McBride

From:

Indiana

|

Posted 31 Jan 2022 7:37 am

Posted 31 Jan 2022 7:37 am |

|

| I'm looking vertical axis instead of horizontal |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 1 Feb 2022 9:23 am

Posted 1 Feb 2022 9:23 am |

|

| Quote: |

| I'm looking vertical axis instead of horizontal |

The window lock you posted is the same one I used in my outdoor shed. I don't believe they will hold up under the string tension. The rivets on the axle are very flimsy. Lots of play in the swivel. I had to fix several of them after only a few uses. I think the vertical axis idea is interesting, not sure how you would activate it that way, but you may be on to something. |

|

|

|

Mike McBride

From:

Indiana

|

Posted 4 Feb 2022 3:00 pm

Posted 4 Feb 2022 3:00 pm |

|

I think a Bigsby type device could be used. You'd have to provide a different anchor point for the other 5 strings perhaps by using screw on stop.

Then wrap the B string the opposite direction around the rotating bar. When arm is lowered, the string would instead be tightened and the pitch raised.

You'd have to use some type of a set screw to limit the travel of the handle for appropriate destination pitch.

Cost of materials: $50 |

|

|

|

Mike McBride

From:

Indiana

|

|

|

|

Mike McBride

From:

Indiana

|

Posted 10 Feb 2022 11:10 am

Posted 10 Feb 2022 11:10 am |

|

Simple but effective

|

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 10 Feb 2022 3:04 pm

Posted 10 Feb 2022 3:04 pm |

|

| Quote: |

| Simple but effective |

Now this is my type of technology! |

|

|

|

Mike McBride

From:

Indiana

|

Posted 11 Feb 2022 5:46 am

Posted 11 Feb 2022 5:46 am |

|

Floor mounted version

|

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 11 Feb 2022 6:12 am

Posted 11 Feb 2022 6:12 am |

|

| As long as it gets you from point A to point B! |

|

|

|

Mike McBride

From:

Indiana

|

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 19 Feb 2022 6:51 am

Posted 19 Feb 2022 6:51 am |

|

| Let us know how it works! I build and engineer things as a hobby, rarely does it end up being easier and or cheaper than just buying something. I'm currently working on a simple pull release pedal steel. For months I was convinced bike brake cable would work easier than pedals and rods. I even tried to come up with a different style changer. None of that worked! I'm having lots of success with old tried and true designs... I may try to come up with a bender of sorts the future. I like to use off the shelf parts from the hardware store when I can. |

|

|

|

John Drury

From:

Gallatin, Tn USA

|

Posted 26 Mar 2022 9:29 pm

Posted 26 Mar 2022 9:29 pm |

|

Mike,

I copied from that very same Ebay ad and built a set very similar, all from scrap aluminum laying around the shop. Actually I built the entire guitar out of scrap material that was laying around the shop.

Your benders are made by a guy in Hawaii, it seems so right!

I copied the guitar from a Montgomery Ward "Rocket Six" that I had when I was a kid. Everything was Rocket this and Space that back then! The Emmons fretboard fit right in to the theme! Ha! And the 24 /4" scale worked out nicely for bends!

The body is made from pressure treated 2 x 4's, sustains like crazy!

The benders work great! Got the project done for under 25 bucks, a few trips to Ace HDWE.. I think I only have about 80 bucks in the whole guitar! The only tools I used were a drill press, hacksaw, and a 8-32 tap.

_________________

John Drury

NTSGA #3

"Practice cures most tone issues" ~ John Suhr

Last edited by John Drury on 27 Mar 2022 7:14 am; edited 1 time in total |

|

|

|

John Drury

From:

Gallatin, Tn USA

|

Posted 27 Mar 2022 6:58 am

Posted 27 Mar 2022 6:58 am |

|

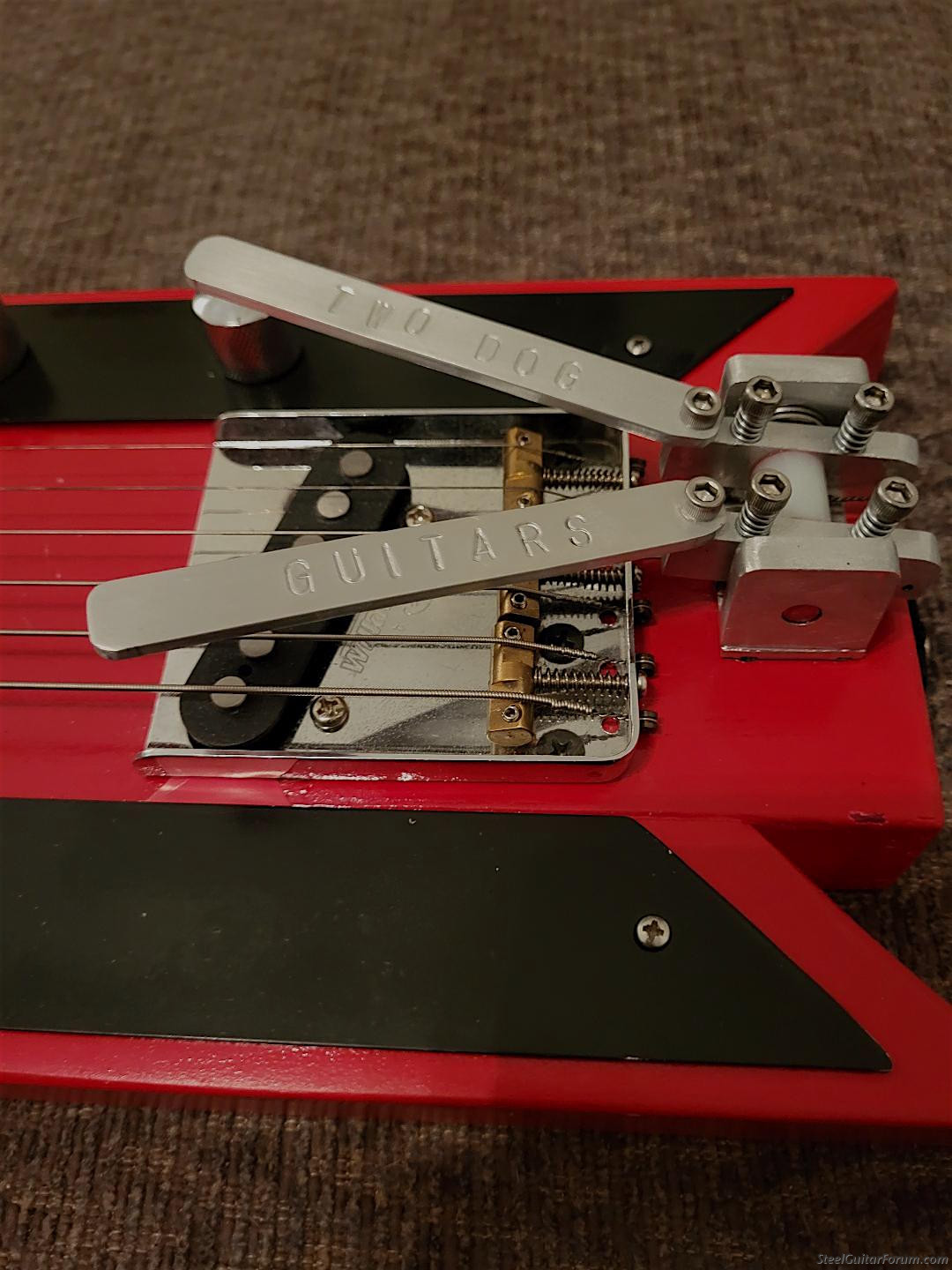

This is a cool set of benders! By forumite Dave Begalka. I wish I had seen this a few weeks ago! Nice work Dave!

_________________

John Drury

NTSGA #3

"Practice cures most tone issues" ~ John Suhr |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 28 Mar 2022 6:09 am

Posted 28 Mar 2022 6:09 am |

|

| Thanks for the pictures! I can clearly see how the mechanism works. This thread (and lots of others) probably belongs over in the builders forum. |

|

|

|

Mike McBride

From:

Indiana

|

|

|

|

Mike McBride

From:

Indiana

|

Posted 5 Mar 2024 7:25 am

Posted 5 Mar 2024 7:25 am |

|

I bought some Pitch Witch benders from Peters Instruments in Muncie Indiana. Installation took about 30 minutes.

I am pleased with the outcome and am working on increasing my skill at finger picking the strings after 47 years of flat picking!

|

|

|

|

BJ Burbach

From:

New York, USA

|

Posted 5 Mar 2024 12:52 pm bent,

Posted 5 Mar 2024 12:52 pm bent, |

|

Tried a bunch of experiments, but to me, nothing beats the light touch of a Doozy.

These days though, just slanting more instead.

One more pic, before the thread police comes for us... but yes, this is a lap steel. B11, with the bender lowering the second string. 20" scale, D'ddario heavy strings.

BJ

Last edited by BJ Burbach on 20 Sep 2024 3:19 pm; edited 1 time in total |

|

|

|

Chris Templeton

From:

The Green Mountain State

|

|

|

|

Mike McBride

From:

Indiana

|

|

|

|