| Author |

Topic: Homebuilt S10 |

Carl Mayer

From:

Richmond, Virginia, USA

|

Posted 17 Dec 2023 3:50 am

Posted 17 Dec 2023 3:50 am |

|

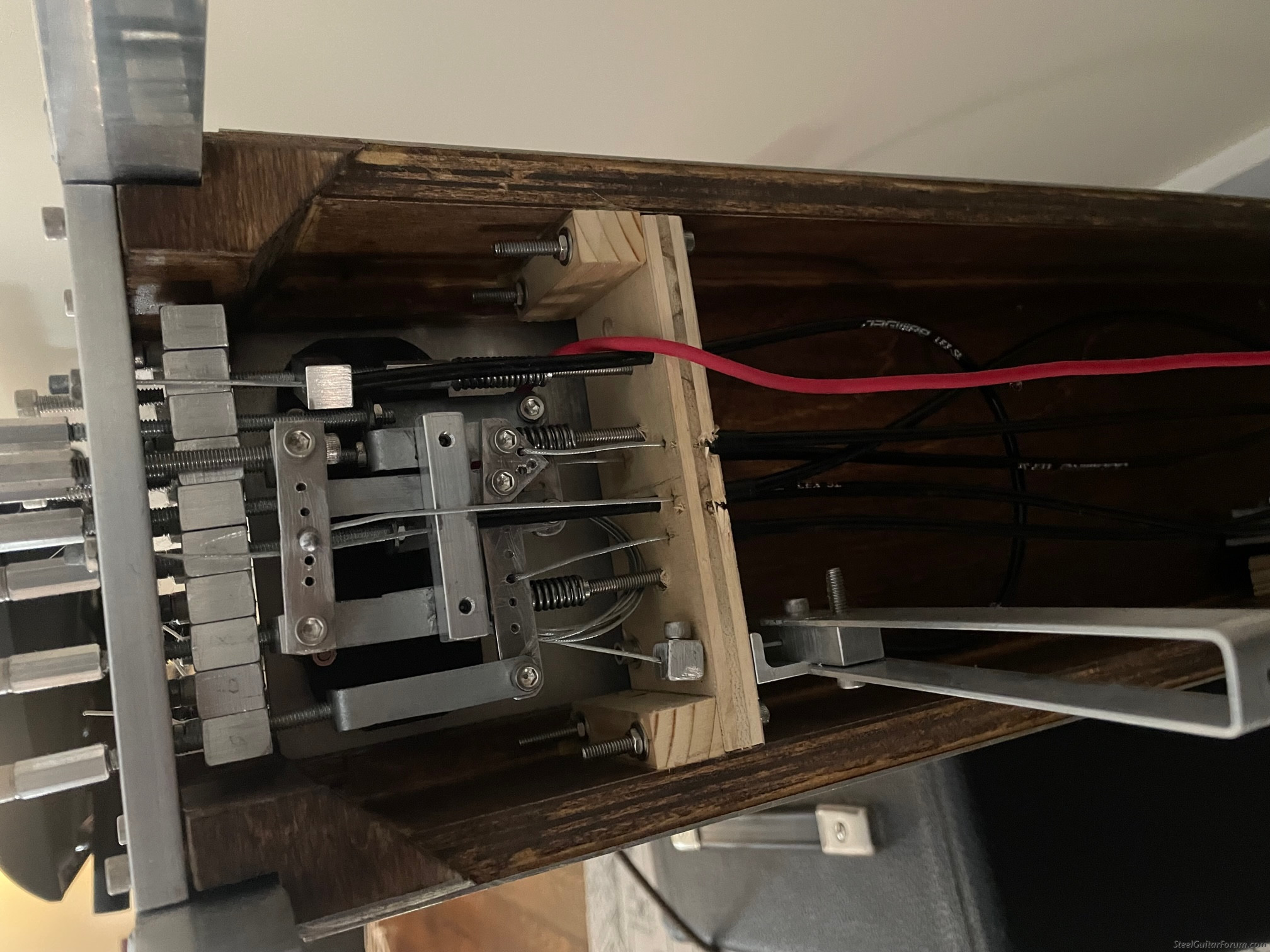

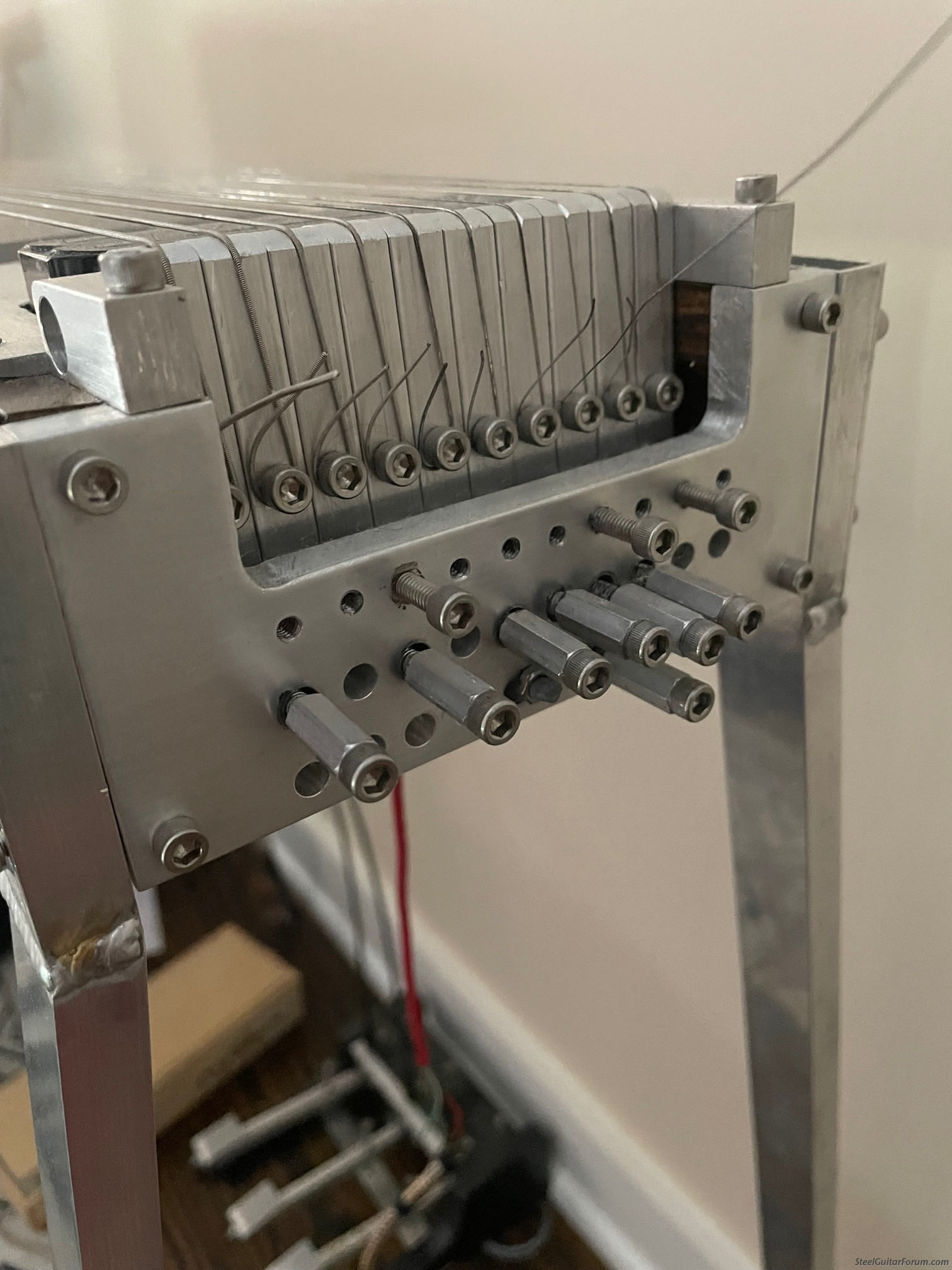

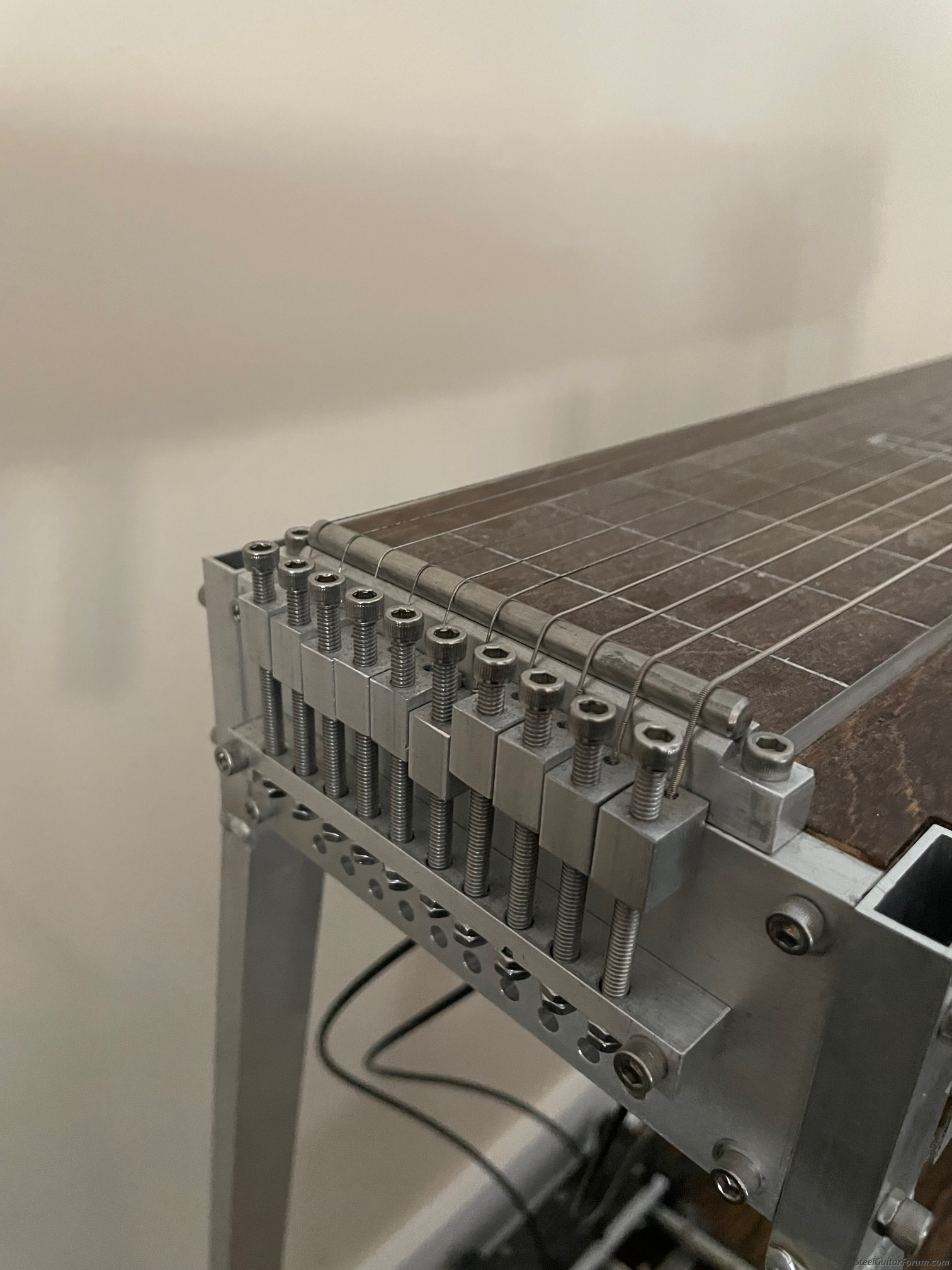

So here are some pics a homebuilt PSG I put together a while back. Its a single neck 10 string set up for the E9 3+3 copedent explained here https://b0b.com/wp/copedents/understanding-e9th/

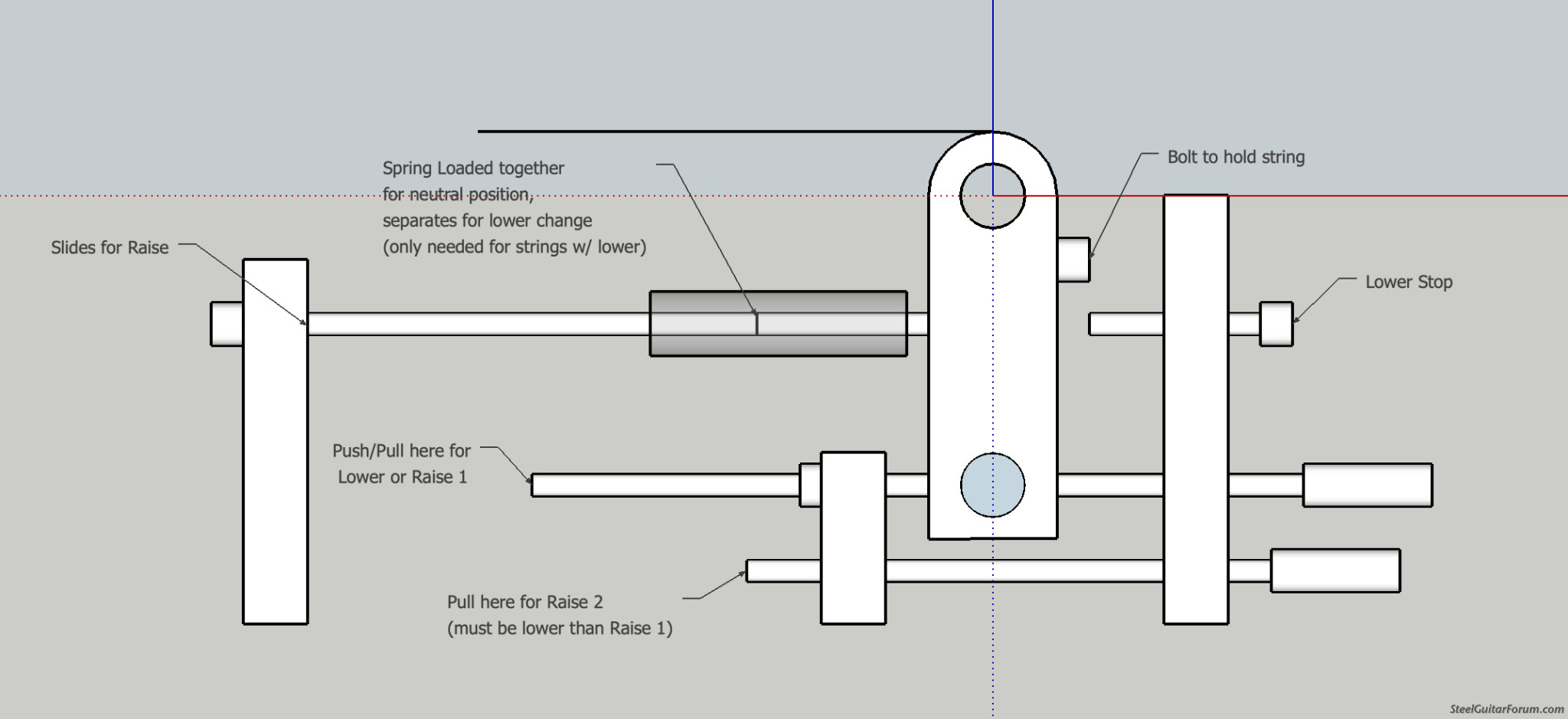

The changer is my own cable driven design and can handle 2 raises and 1 lower without much trouble, more complicated stuff might be possible with some creativity. Its hard to tell whats going on with the changer so a diagram of how it works is below. It could definitely use some refinement but there are some perks to the design and its functional enough for learning on.

The pros:

Total weight is only 10-1/2 lbs, good considering the complaints I see on this forum about lugging 50-100lb around but I do need to get around to adding some larger rubber feet or something to keep from pushing it around with the knee levers. The changer design is simple enough that I made it with just a drill press and hand tools, though a little finicky to get set up and not much working space.

The cons:

With the headless tuners and small changer the whole thing is only like 26” so leg room is a little tight. The knee lever and pedal travels are pretty short and high force. I’ve never touched a factory one though and was just winging it for this one so before I dig into another project I’ll post some questions regarding what ranges are typical for that and other ergonomics type stuff.

Anyway some pics are below:

|

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 7 Jan 2024 11:31 pm

Posted 7 Jan 2024 11:31 pm |

|

That is a very neat looking set up. With movable pedal group would be great for someone with foot or leg damage.

With the pedal stops on the pedals, Does the pull tuning change much with temperature change?

Does the guitar have any Cabinet Drop when the A & B pedals are shoved down? |

|

|

|

Carl Mayer

From:

Richmond, Virginia, USA

|

Posted 8 Jan 2024 1:49 pm

Posted 8 Jan 2024 1:49 pm |

|

| Bobby D. Jones wrote: |

That is a very neat looking set up. With movable pedal group would be great for someone with foot or leg damage.

With the pedal stops on the pedals, Does the pull tuning change much with temperature change?

Does the guitar have any Cabinet Drop when the A & B pedals are shoved down? |

Thanks! So the actual tuning is still done on the end plate and doesn’t seem to be temperature dependent, the stops on the pedals are just to keep me from putting too much force on the cables and slipping the cable clamp (or worse breaking a cable). I haven’t really noticed any cabinet drop but I’m not a good enough player to be discerning yet. Cabinet drop should be more a function of the changer axle stiffness and height of the strings above the deck (which is very low on this) cable vs pull rod I wouldn’t think would make much difference but I could be wrong. |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 9 Jan 2024 1:12 am

Posted 9 Jan 2024 1:12 am |

|

Mechanically Pedal rods are hooked to the pedal at the pedal bar, And the other end is attached to the front apron, Connected to the cross shaft on most guitars. The pedal stop is on the front apron too. When the pedal is pushed down to the stop. All the pull pressure is put on the front apron. It can detune the 4th E string , When the A&B pedals are engaged together.

Since the pull from the pedals on your guitar is horizonal in the body, Would not put down pressure on the front apron.

In this picture the pedals have about a 3 to 1 lever ratio advantage, Pulling down on the body front apron.

Good Luck and Happy Steelin. |

|

|

|

Carl Mayer

From:

Richmond, Virginia, USA

|

Posted 9 Jan 2024 3:13 am

Posted 9 Jan 2024 3:13 am |

|

Oh I always assumed the detuning was from the extra 10-20lbf of string tension deflecting the changer axle and releasing some tension on the remaining strings (like if you break/remove a string on an acoustic the pitch of the others goes up because the top and neck aren’t being deflected as much)

Since it’s from downward pressure you could fix it on existing guitars pretty easily, just put one or more turnbuckles or fixed length braces from the front to back the guitar near the bottom of the skirt. The whole body is like one big c channel beam so if you tie the front and back together it acts like a full box tube at that position (and halves the span of the remaining c channel parts) and the stiffness in bending goes way up. |

|

|

|

Aaron Seither

From:

California, USA

|

Posted 4 Mar 2024 10:59 am

Posted 4 Mar 2024 10:59 am |

|

| I love this, and have been kicking around ideas (as well as lugging around parts) for over a decade to make a lap steel with bike cable-attached ABC pedals taken from an old piano and housed in a stand alone box. Was gonna call it a Pedal Steal. Anyway, I couldn’t find anything like it on the net for all that time, and just in this last week have come across a handful of examples of folks putting many of these same ideas into practice. When it rains, it pours. I’m encouraged by your ingenuity and look forward to getting the sounds I love at my fingertips. |

|

|

|

Jon Zimmerman

From:

California, USA

|

Posted 27 Jul 2024 7:48 am Pull-string Architecture

Posted 27 Jul 2024 7:48 am Pull-string Architecture |

|

| Great example of a ‘Builders Corner’ project, Carl. I see you’ve even constructed a volume pedal in the pics. You have a rare, capacious, 3D mind and hands-on ability to pull up an idea on paper into real-world build ups. Continued success in refining these ideas, Carl. Watchmaking “101” uses the same concepts, only with different materials and complexities of scale than yours, but the goals- reliable functions and accuracy, (along with quick setup & teardown) are the desired end results. Carry on! 😎 |

|

|

|

Wayne Baker

From:

Altus Oklahoma

|

Posted 16 Aug 2024 3:07 pm Builder

Posted 16 Aug 2024 3:07 pm Builder |

|

I like this alot. Very inspiring.

_________________

Thanks,

Wayne Baker

USAF retired, three wars, 21 years, 18 countries. God bless the USA |

|

|

|