| Author |

Topic: AB Pot Needs Some TLC |

Don Mogle

From:

Round Rock, TX, USA

|

Posted 1 Dec 2018 7:23 am

Posted 1 Dec 2018 7:23 am |

|

Hi,

I was wondering if anyone out there has experience diagnosing problems, repairing and fixing AB pots?

I have one that I took out of a Goodrich pedal a few years ago because it was going bad. I can't remember what the exact problem was...could have just been scratchy.

At any rate, is there anyone out there who has the knowledge and experience to open it up, take a look, let me know if it can be repaired, and fix the problem?

They don't seem to make them like these anymore and I'd like to give it an opportunity to provide additional service.

Thanks,

Don |

|

|

|

John Swain

From:

Winchester, Va

|

Posted 1 Dec 2018 7:53 am

Posted 1 Dec 2018 7:53 am |

|

| Don, I usually drill a small hole in the metal cover and spray Deoxcit inside. I've pulled the cover off some in the past and "sanded" between the wiper and the carbon ring with a small piece of brown paper bag. This sometimes helps. There was talk in the 80's of lowering(by bending) the tension on the wiper,but I remember if the results were consistent. |

|

|

|

George Kimery

From:

Limestone, TN, USA

|

Posted 1 Dec 2018 9:03 am AB pot needs some tlc

Posted 1 Dec 2018 9:03 am AB pot needs some tlc |

|

I don't know if J Dee Maness would want to mess with it if not, but in a conversation with him at the Dallas show, he mentioned that you can take the cover off and clean the wiper.

You can still find them on ebay. Some are new, some are rebuilt. 500 K, long shaft. The taper on most of them is linear instead of the preferred algorithmic. |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 1 Dec 2018 10:50 am

Posted 1 Dec 2018 10:50 am |

|

When cleaning/lubing the pots, you must keep in mind that there are two wipers. One is on the outside, and it contacts the carbon ring. The other wiper is a sliding contact nearer to the inside that carries the continuity from the wiper, to a contact ring, to the center contact of the pot. Either one being dirty or worn may cause noise.

I recommend removing the cover, as opposed to drilling it, so as not to get metal particles inside the pot. Also, lubing the pots when they are new (before you install them), is the best way to get the longest life out of them. |

|

|

|

Greg Cutshaw

From:

Corry, PA, USA

|

Posted 1 Dec 2018 11:23 am

Posted 1 Dec 2018 11:23 am |

|

I tore one of these apart that had a few years on it. The carbon in the track wiper was wore down to expose its metal holder. So the metal carbon pad holder was rubbing directly on the carbon track and starting to destroy the track while making a lot of electrical noise (scratching sound in the audio). This is typical of worn out pots with millions of cycles and no amount of DeOxit will do any good in this case. See pics below:

|

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 1 Dec 2018 11:27 am

Posted 1 Dec 2018 11:27 am |

|

I've got 2 Type J Mexico AB long shaft pots on the bench right now. I'm attempting to examine them best I can. I can see that the wiper is worn down on one of them. I have a way to replace that thanks to a tip from Willie Sims.

The other thing, the carbon track on the body, is another deal.

First, I need to know what determines the impedance. I have some conductive material I can add to that surface that I think will work.

It's a study in progress. I'm hoping to come up with a fix because the new pots just don't sound the same as these old AB ones plus the travel and taper is a bit different.

Another caution concerning trying to clean them by spraying, never use any cleaner with a solvent as that will likely destroy the resistive element. Per Donny, trying to clean through a drilled hole, you just can't get the debris and old original worn off material out that way.

Note and mark clearly the orientation of the little stop tab on the shaft when you take it apart and put it back the same way it was.

Last edited by Jerry Overstreet on 1 Dec 2018 12:19 pm; edited 1 time in total |

|

|

|

Don Mogle

From:

Round Rock, TX, USA

|

Posted 1 Dec 2018 11:57 am AB Pot

Posted 1 Dec 2018 11:57 am AB Pot |

|

| Thanks fellas for all the advice! |

|

|

|

Larry Dering

From:

Missouri, USA

|

Posted 2 Dec 2018 4:01 am

Posted 2 Dec 2018 4:01 am |

|

| Interesting post. I'd like to know the results of fixing the pot. |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 2 Dec 2018 7:23 am

Posted 2 Dec 2018 7:23 am |

|

This tip goes along with what Greg has mentioned. If the carbon block has worn down a lot, and the metal holder is touching (or nearly touching) the resistive element, you can sometimes gain a little life by turning the block on it's side.  |

|

|

|

Greg Cutshaw

From:

Corry, PA, USA

|

Posted 2 Dec 2018 9:41 am

Posted 2 Dec 2018 9:41 am |

|

| When I rebuild our old 1940's elevator electrical contactors at work, i just buy a block of carbon and have the tool room machine it down and rebuild them. There are so many great conductive plastic pots available nowadays I can't imagine myself messing around with an old Allen Bradley pot! |

|

|

|

Doug Earnest

From:

Branson, MO USA

|

Posted 2 Dec 2018 10:15 am

Posted 2 Dec 2018 10:15 am |

|

Greg, do you know if any of these new conductive plastic pots have a taper similar to the old AB pots?

I use the Dunlop hot potz and am satisfied with the performance other than the taper, which takes a bit of getting used to.

You do a great job of reviewing products! It is appreciated. |

|

|

|

Greg Cutshaw

From:

Corry, PA, USA

|

Posted 2 Dec 2018 11:27 am

Posted 2 Dec 2018 11:27 am |

|

The HotPotz has a slightly different taper than the old AB pots. That never much bothered me. I could use either one. There have been newer conductive plastic pots introduced since the HopPotz that claim to have the AB taper. This would include the new Goodrich pot:

http://www.steelguitarscanada.com/online-store/products-page-2/goodrich-volume-pedals/goodrich-pot-pigtailed/

Quote:

"The new owners of Goodrich Sound knew when they bought the Goodrich Company their biggest obstacle was the potentiometer. After some serious and painstaking R&D, testing out pots from every manufacturer too numerous to list here, by some crazy luck we found the engineer that designed all the pots for Dunlop. We talked with this guy and his company agreed to design what we needed. These are not cheap pots for us but we felt they would be worth it.

We really liked some of the aspects of the Dunlop 470k HotPotz that he designed and Dunlop sells.. We wanted a pot that had a +/- threshold of 5% or less... That's in mechanical and electrical values. Also we wanted an Allen Bradley type audio taper. We wanted a pot that had an extremely long life, trouble free. We wanted an easy, smooth spin and a longer, slotted shaft. We got everything we asked for... This is the new standard.. We guarantee these pots for one year from the time of purchase... No questions asked!" |

|

|

|

Steven Paris

From:

Los Angeles

|

Posted 2 Dec 2018 8:01 pm

Posted 2 Dec 2018 8:01 pm |

|

What's the difference between an "Allen Bradley type audio taper" and a regular audio (log) taper?

_________________

Emmons & Peavey |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 3 Dec 2018 8:35 am

Posted 3 Dec 2018 8:35 am |

|

| There's a very slight difference in the sweep (rotation vs. resistance) of the two...not enough for me to notice, but the small difference (10%-15% near the end of the rotation) seems to bother some players. |

|

|

|

Greg Cutshaw

From:

Corry, PA, USA

|

Posted 3 Dec 2018 8:41 am

Posted 3 Dec 2018 8:41 am |

|

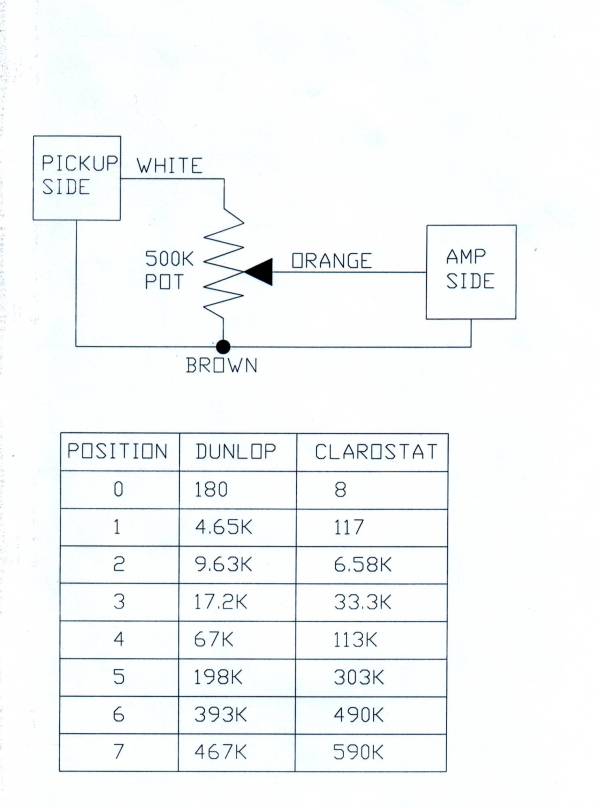

I measured each pot at zero degrees rotation and then in 14 degree steps up to full rotation. And the taper is not just different at the end of the rotation. It varies all along the track.

|

|

|

|

kevin ryan

From:

San Marcos, California

|

Posted 3 Dec 2018 11:16 am

Posted 3 Dec 2018 11:16 am |

|

Greg.. Thank you so much for your thoughtful testing and descriptions. Our goal in pot reguirements was to have a pot that would have a long life, low capacitance, and be audio tapered or "J tapered" . I think we have a pretty good substitute for the AB's. They are different in taper and in sound I will say.. I have a-b'd so many pots that its now hard to say what is "good".. I will say that I have found with players, that the communication between your head and ears with your foot, WILL find the sweet spot that you need in the taper and will get use to it very quickly.. Not as critical as I hear.. I have done blind tests with players and mixing in different pots and tapers and the players find it very difficult to distinguish what they don't like and what they like.. The resistance and rotation graph you provided is an excellent example. Thank you for that. Players would be surprised to know that although those numbers look different, in real world usage, they are very similar in feel and tone.

Last edited by kevin ryan on 12 Dec 2018 9:16 am; edited 1 time in total |

|

|

|

Bob Carlucci

From:

Candor, New York, USA

|

Posted 3 Dec 2018 12:30 pm

Posted 3 Dec 2018 12:30 pm |

|

Entirely too much craziness when it comes to the perceived "magic" of the old AB 500 K pots. They are pretty much gone, and the Dunlop 470 is a perfectly good substitute... Yes they have a different taper, but an experienced steel player, or even an inexperienced one would have all the problems worked in an hour of playing.. I have repaired AB pots in different ways, and a few months later was putting in a new pot anyway.. those "innards" are all 40-50 years old at this point, and even when I had a few unused AB pots a few years ago, they didn't hold up the way they did back in the 70's, and within a year i was installing dunlops... bob

_________________

I'm over the hill and hittin'rocks on the way down!

no gear list for me.. you don't have the time...... |

|

|

|

Morton Kellas

From:

Chazy, NY, USA 1

|

Posted 9 Dec 2018 8:53 am

Posted 9 Dec 2018 8:53 am |

|

| Is the taper the same on a Dunlop 470 vs a Goodrich 470? I don't see how it can be any different with the pot diameter being the same. Please correct me if I am wrong. It looks like the only difference is that Goodrich has a longer slotted shaft and attached leads. I would like to know what they may have done internally to make this pot any better than the Dunlop. Dunlop makes a great substitute pot and if Goodrich has done something to improve on what is already good, I will be looking to get one. Thanks |

|

|

|

kevin ryan

From:

San Marcos, California

|

Posted 10 Dec 2018 10:42 am

Posted 10 Dec 2018 10:42 am |

|

| Morton I can't speak for the Dunlops other than they are great pots and consistent. Dunlop did not make those pots. We supplied the engineer with our rotation/resistance characteristics that we required. Along with our other requirements, they met our needs. They are very similar to the pots Dunlop sells. Hope this helps. |

|

|

|

Willie Sims

From:

PADUCAH, KY, USA

|

Posted 10 Dec 2018 10:52 am

Posted 10 Dec 2018 10:52 am |

|

| I POSTED SOME TIME AGO HOW TO REPAIR ALLEN BRADLEY POTS,YOU MIGHT FIND IT UNDER ALL POST;S BY WILLIE SIMS. |

|

|

|

Larry Dering

From:

Missouri, USA

|

|

|

|

Don Mogle

From:

Round Rock, TX, USA

|

Posted 11 Dec 2018 5:28 pm

Posted 11 Dec 2018 5:28 pm |

|

| Thanks to all who've responded with knowledge and insight! |

|

|

|