| Author |

Topic: Simple diagram for a DIY homemade string bender |

Andrew Owen

From:

Texas, USA

|

Posted 6 Nov 2016 11:53 am

Posted 6 Nov 2016 11:53 am |

|

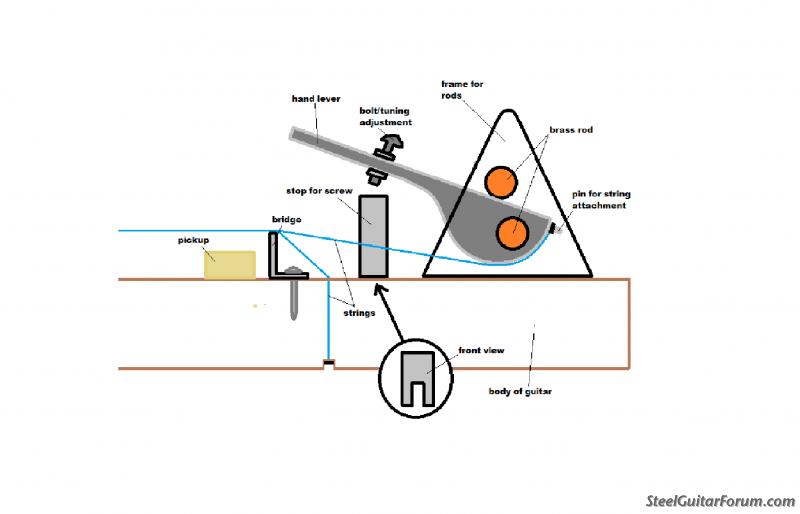

So, here goes my first post! I'd been thinking for a few weeks on, for me, the simplest string bender possible to make with stuff laying around the garage, or could go pick up at a store. So, I kept this in mind when thinking it out. I'm fairly certain that this bender can be made from just wood, two brass rods, and a metal pin. Let me know what y'all think and if there's any improvements that can be made. Or, if there's something about it that is impossible or just won't work like I'm thinking. Also, if you use it, let me know! I plan on trying it out at some point, but I have to build the rest of the guitar first.

|

|

|

|

Jeff Mead

From:

London, England

|

Posted 6 Nov 2016 12:03 pm

Posted 6 Nov 2016 12:03 pm |

|

Should work. It's pretty much a Bigsby palm pedal.

Not sure about making it from wood though. I'm a bit heavy handed and it would be luck to make it through a gig. |

|

|

|

Andrew Owen

From:

Texas, USA

|

Posted 6 Nov 2016 12:08 pm

Posted 6 Nov 2016 12:08 pm |

|

Jeff Mead, I pretty much just tried to simplify the bigsby and the deusenberg multibender as much as possible. Those units aren't very complex, but building them out of solid steel would be.  For me, at least. So, I think besides the brass rods, the bolt, and the nuts, the rest could all be wooden. Pretty simple I think. To make two of these would probably cost around maybe 15, 20 dollars? For me, at least. So, I think besides the brass rods, the bolt, and the nuts, the rest could all be wooden. Pretty simple I think. To make two of these would probably cost around maybe 15, 20 dollars? |

|

|

|

Andrew Owen

From:

Texas, USA

|

Posted 6 Nov 2016 12:10 pm

Posted 6 Nov 2016 12:10 pm |

|

| Or, the lever and the stop could probably be made from aluminum pretty easily. Even the a-frame that holds the rods. I've never tried cutting aluminum on my band saw, but I think it'd work alright! |

|

|

|

Jeff Mead

From:

London, England

|

Posted 6 Nov 2016 12:14 pm

Posted 6 Nov 2016 12:14 pm |

|

| Yrs, I think the lever and stop would need to be aluminium |

|

|

|

Andrew Owen

From:

Texas, USA

|

Posted 6 Nov 2016 12:29 pm

Posted 6 Nov 2016 12:29 pm |

|

| Thanks, Jeff! I've played guitar for years and years, but have actually never even touched a steel guitar. So I appreciate the advice! I'm stoked to learn, but will have to wait until I have all the pieces to build the one I want. And I really want two benders, hahaha. |

|

|

|

Larry Phleger

From:

DuBois, PA

|

Posted 6 Nov 2016 12:39 pm

Posted 6 Nov 2016 12:39 pm |

|

Putting a roller in the slot on the bottom of the block to stop the screw might help reduce string breakage. A barrel end from an old string with a pin through the hole might serve the purpose. I agree with Jeff that aluminum would add stability to your design. It is easy to work with using common shop tools. Your design looks great. Be sure to let us know how it works out.  |

|

|

|

Andrew Owen

From:

Texas, USA

|

Posted 6 Nov 2016 12:46 pm

Posted 6 Nov 2016 12:46 pm |

|

| Larry, I love your idea of using an old string barrel as a roller. That's genius. that's definitely going in the final design. And thank you! Once it gets all put together, you can rest assured that I'll be sharing plenty of pictures with my new online community, lol. |

|

|

|

Brad Higgins

From:

New York, USA

|

|

|

|