| Author |

Topic: Photos of Bakelite Neck Repair |

Howard Clark

From:

Brookston, Indiana, USA

|

Posted 1 Jun 2005 10:17 pm

Posted 1 Jun 2005 10:17 pm |

|

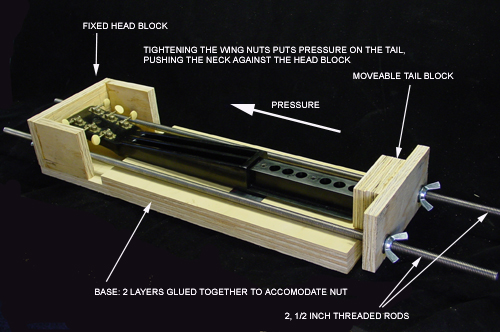

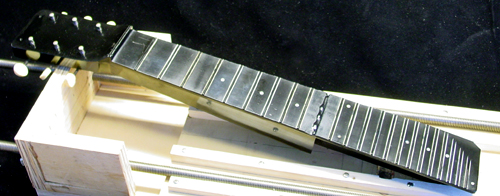

I repaired broken neck the early forties Bakelite Rickenbacher using the Wayne Tanner method suggested to me by Roy Montee. I ordered the Brownell's AcraGlas at a local gun shop and while waiting for it to arrive, I built a clamping gizmo out of 3/4 inch plywood.

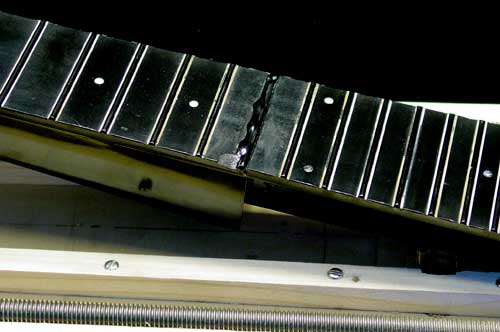

The neck pieces fit together perfectly, but when I laid them on the plywood there was a slight gap at the fretboard side, careful examination showed that the neck was slightly bowed. If I didn't know better, I would say that it was neck relief, the slight bowing in a regular guitar neck to compensate for the fact that the greatest amplitude of vibration of a string is at it's center. I suppose the bowing is caused by "creep," deformation caused by 60 years of string tension.

I discovered that if I held the peg head and pushed on the tail end of the neck, the pieces would line up perfectly. I built the gizmo with a loose piece at the tail end and two half-inch threaded rods with wing nuts to apply pressure.

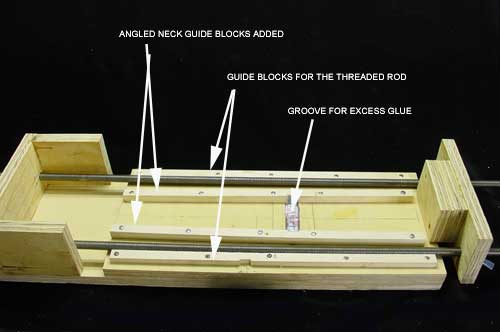

This worked fine except that the neck wasn't perfectly straight. I added two strips of wood on either side of the neck. the neck is a perfect taper from tail end of the fretboard to the nut, so pressure from the wing nuts would actually force it into alighnment. I also added to more strips of wood to keep the threaded rod in alignment. I made a groove underneath the joint and lined it with aluminum tape, so that any drips wouldn't glue the neck to the gizmo.

This worked fine so I mixed up the epoxy, which is mixed 4 to 1 epoxy to hardener. I have two matching sets of stainless steel measuring spoons, so I used one 1/4-teaspoon to scoop out 4 spoonfuls of epoxy resin and the other to measure out one 1/4-teaspoon of hardener. I poured them into a stainless steel measuring cup and stirred for 2 minutes. I then put in 2 drops of black colorant and contued stirring for 2 more minutes. I brushed it on both pieces with a throwaway brush, stuck them together and put the neck into the gizmo, and snugged up the wing nuts. I then turned the wing nuts until it was solid and hard to turn, but I didn't overdo it.

The instructions say that the epoxy reaches full strength after 2-1/2 days, so I left it in for 3 days.

I'll be able to sand down the excess to match the other frets. There is plenty of resin left to fill the low spots where chips popped out.

I strung it up this evening, it sounds wonderful!

Howie Clark[This message was edited by Howard Clark on 01 June 2005 at 11:57 PM.] |

|

|

|

Joel Newman

From:

Smithsburg, Maryland, USA

|

Posted 2 Jun 2005 6:06 am

Posted 2 Jun 2005 6:06 am |

|

| Wow!! Bravo Howard, well done. Perish the thought of anyone else needing that kind 'o TLC for thier bakelite but don't ever throw your 'gizmo' away. . . . |

|

|

|

Terry Farmer

From:

Albuquerque, New Mexico, USA

|

Posted 2 Jun 2005 6:17 am

Posted 2 Jun 2005 6:17 am |

|

| My hat is off to you, sir! |

|

|

|

Denny Turner

From:

Oahu, Hawaii USA

|

Posted 2 Jun 2005 6:24 am

Posted 2 Jun 2005 6:24 am |

|

What excellently planned and executed work, Howard. BRAVO indeed. And THANK YOU for sharing it with us.

Aloha,

DT~

|

|

|

|

Bob Stone

From:

Gainesville, FL, USA

|

Posted 2 Jun 2005 6:44 am

Posted 2 Jun 2005 6:44 am |

|

Howard,

Thanks a million. Your photo illustrations are wonderful. I hope I never have to use this information, but if i do this sounds like the method.

Hats off to Wayne Tanner too.

Bob |

|

|

|

Gerald Ross

From:

Ann Arbor, Michigan, USA

|

Posted 2 Jun 2005 6:52 am

Posted 2 Jun 2005 6:52 am |

|

Howie,

Incredible!! Beautiful work. Well thought out, not rushed and thorough.

You, Wayne Tanner, Bill Creller and Rick Aiello have done a great deal and added to the knowledge base that keeps these old instruments alive and well. Thank you.

See you at the Winchester Aloha convention next month?

------------------

Gerald Ross

'Northwest Ann Arbor, Michigan's King Of The Hawaiian Steel Guitar'

Gerald's Fingerstyle Guitar Website

Board of Directors Hawaiian Steel Guitar Association

[This message was edited by Gerald Ross on 02 June 2005 at 07:53 AM.] |

|

|

|

Michael Aspinwall

From:

Arizona, USA

|

Posted 2 Jun 2005 2:47 pm

Posted 2 Jun 2005 2:47 pm |

|

| Your photos & graphics ROCK!! Do you do this for a living?? |

|

|

|

Rick Aiello

From:

Berryville, VA USA

|

Posted 2 Jun 2005 2:51 pm

Posted 2 Jun 2005 2:51 pm |

|

What a marvelous job !!!!

------------------

Aiello's House of Gauss

My wife and I don't think alike. She donates money to the homeless and I donate money to the topless! ... R. Dangerfield

|

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 2 Jun 2005 2:53 pm

Posted 2 Jun 2005 2:53 pm |

|

| Great job, superb presentation. |

|

|

|

Danny James

From:

Summerfield Florida USA

|

Posted 2 Jun 2005 3:15 pm

Posted 2 Jun 2005 3:15 pm |

|

| That's the kind of work anyone should be proud of. A++ |

|

|

|

Bill Creller

From:

Saginaw, Michigan, USA (deceased)

|

Posted 2 Jun 2005 6:06 pm

Posted 2 Jun 2005 6:06 pm |

|

That was a fine job, and well thought out.Like everyone else said,I hope to never have to do it again. Great work!!

BILL |

|

|

|

Howard Clark

From:

Brookston, Indiana, USA

|

Posted 3 Jun 2005 5:55 am

Posted 3 Jun 2005 5:55 am |

|

Thanks for the compliments, but it would be in a UPS scrap sale without the Steel Guitar Forum. Thanks to everyone for your help.

Howie |

|

|

|

HowardR

From:

N.Y.C.-Fire Island-Asheville

|

Posted 3 Jun 2005 9:22 am

Posted 3 Jun 2005 9:22 am |

|

Very excellent as everyone else has stated.

Please don't let my ex get a hold of your device. My voice is high enough!  |

|

|

|