| Author |

Topic: Uh, oh… not again. |

Bob Knetzger

From:

Kirkland, WA USA

|

Posted 23 Jan 2025 4:39 pm

Posted 23 Jan 2025 4:39 pm |

|

This is the second knee lever part that dramatically failed on my 2002 Carter.

I know, I know: don’t press so hard!

Last time it happened on the bandstand, ugh. Fortunately it was a seldom used RKR working both necks and did the E9 second string double lower as well as the C6 neck 3rd string lower, so pressing against 4 return springs at full travel.

This time it was at home (whew!) and the more often used LKR lowering both E’s on E9. Sure has had many thousands of cycles over 23 years. This time I had a replacement part ready for quick swap out.

Still, I think this is a design flaw. The sharp inside corner on that lever crank is just asking for a stress crack. The reversing mechanism has two cranks sliding against each other with a sliding leverage design I just don’t think is smart. I keep it well lubricated with lithium grease. Notable that both failures were on left moving lever thru this type of linkage.

Anybody else have this problem on a Carter?

|

|

|

|

Dave Magram

From:

San Jose, California, USA

|

Posted 23 Jan 2025 10:59 pm

Posted 23 Jan 2025 10:59 pm |

|

Bob,

You are correct--that is a design flaw.

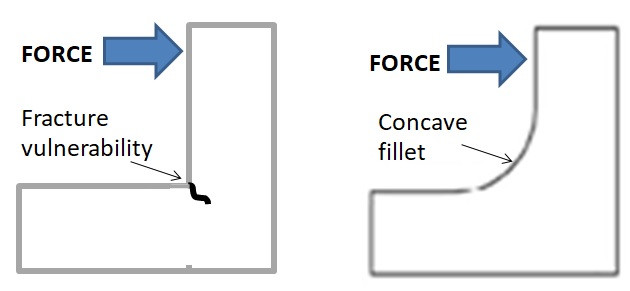

Machined aluminum parts that receive forces from two different directions—as bell-cranks do—are prone to stress fractures if their corners are machined as simple 90-degree angles.

To reduce the possibility of stress fractures, such parts should have a concave “fillet” (pronounced "fil-let") machined in their corners, as shown in the diagram below…

Several years ago, I replaced a knee lever on Bobby Black’s Carter D-10 that had developed a stress fracture similar to the drawing above—and I was rather surprised that the company was not using fillets for added strength on such a highly-stressed part.

- Dave |

|

|

|

Howard Parker

From:

Maryland

|

Posted 24 Jan 2025 6:52 am

Posted 24 Jan 2025 6:52 am |

|

Yep,

The reverser. Drilled mine out and installed a steel roll pin.

That took care of the issue permanently.

hp

_________________

Howard Parker

03\' Carter D-10

70\'s Dekley D-10

52\' Fender Custom

Many guitars by Paul Beard

|

|

|

|

John Swain

From:

Winchester, Va

|

Posted 24 Jan 2025 7:01 am

Posted 24 Jan 2025 7:01 am |

|

| I replaced one on one out of 4 Carters I've owned. There was a tech in Ohio who installed a roller bearing on that piece, that looked like a great prevented repair. He built BSG? Guitars. |

|

|

|

Wayne Brown

From:

Bassano, Alberta, Canada

|

Posted 24 Jan 2025 8:57 am Steel Guitar Parts

Posted 24 Jan 2025 8:57 am Steel Guitar Parts |

|

I think I'll look into this. It does seem like this fillet be a viable solution for this issue

thanks

wayne

_________________

Owner Out West Music,Parts and accessories.

Steel Guitar service and Restoration

www.outwestcountry.ca |

|

|

|

Joseph Carlson

From:

Grass Valley, California, USA

|

Posted 24 Jan 2025 9:26 am

Posted 24 Jan 2025 9:26 am |

|

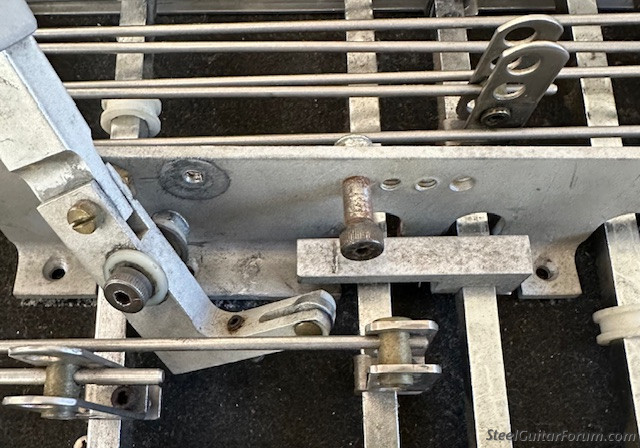

This is how the reverse pull looks on a Derby. Seems like a better design option. Also, quite a bit more robust that the Carter levers I have seen.

|

|

|

|

Richard Sinkler

From:

aka: Rusty Strings -- Missoula, Montana

|

Posted 24 Jan 2025 11:03 am

Posted 24 Jan 2025 11:03 am |

|

My Carter turns 26 years old this year. Only failed parts for me were 2 brass pull pins (dog bones), of course broken on gigs, and a pull bar (bellcrank).

_________________

Carter D10 8p/8k, Dekley S10 3p/4k C6 setup,Regal RD40 Dobro, Recording King Professional Dobro, NV400, NV112,Ibanez Gio guitar, Epiphone SG Special (open D slide guitar) . Playing for 55 years and still counting. |

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 24 Jan 2025 12:08 pm

Posted 24 Jan 2025 12:08 pm |

|

| Emergency repair, drill and screw on a hardware store steel L bracket or....one on ea. side through bolted on. |

|

|

|

Howard Parker

From:

Maryland

|

Posted 24 Jan 2025 12:49 pm

Posted 24 Jan 2025 12:49 pm |

|

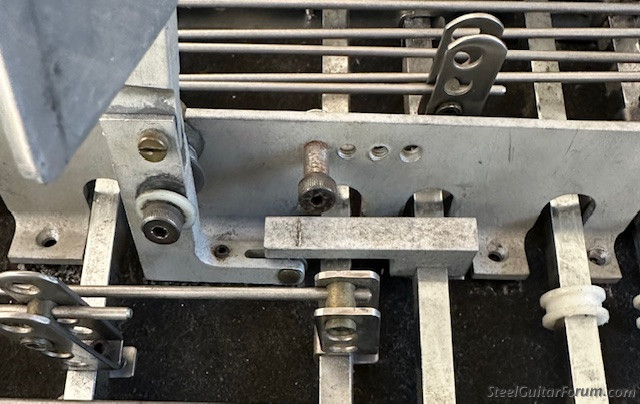

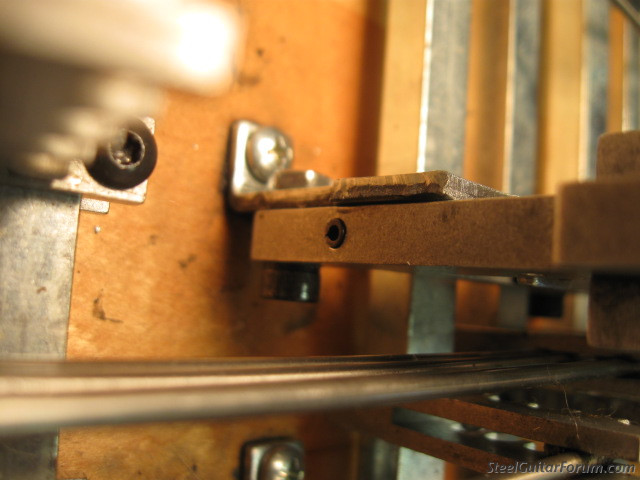

For reference. This was the fix in my case:

[/img] [/img]

|

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 24 Jan 2025 1:24 pm

Posted 24 Jan 2025 1:24 pm |

|

Great idea Howard. I see now, you installed the pin into the 90º tang/elbow to strenghten and reinforce the angle.

Can you recommend a pin length/size? |

|

|

|

Howard Parker

From:

Maryland

|

Posted 24 Jan 2025 1:47 pm

Posted 24 Jan 2025 1:47 pm |

|

Unfortunately I don't recall as the fix was done maybe 12-15 years ago.

Lynn Kasdorf came up with the idea and execution of same. He repaired the afflicted knee and modded a second knee for me.

- edit to add. I don know that the length was all that critical. I suspect Lynn used whatever he had around and just ground down any excess |

|

|

|