| Author |

Topic: Alternate Changer Mechanism |

Les Ford

From:

British Columbia, Canada

|

Posted 12 Dec 2024 6:39 pm

Posted 12 Dec 2024 6:39 pm |

|

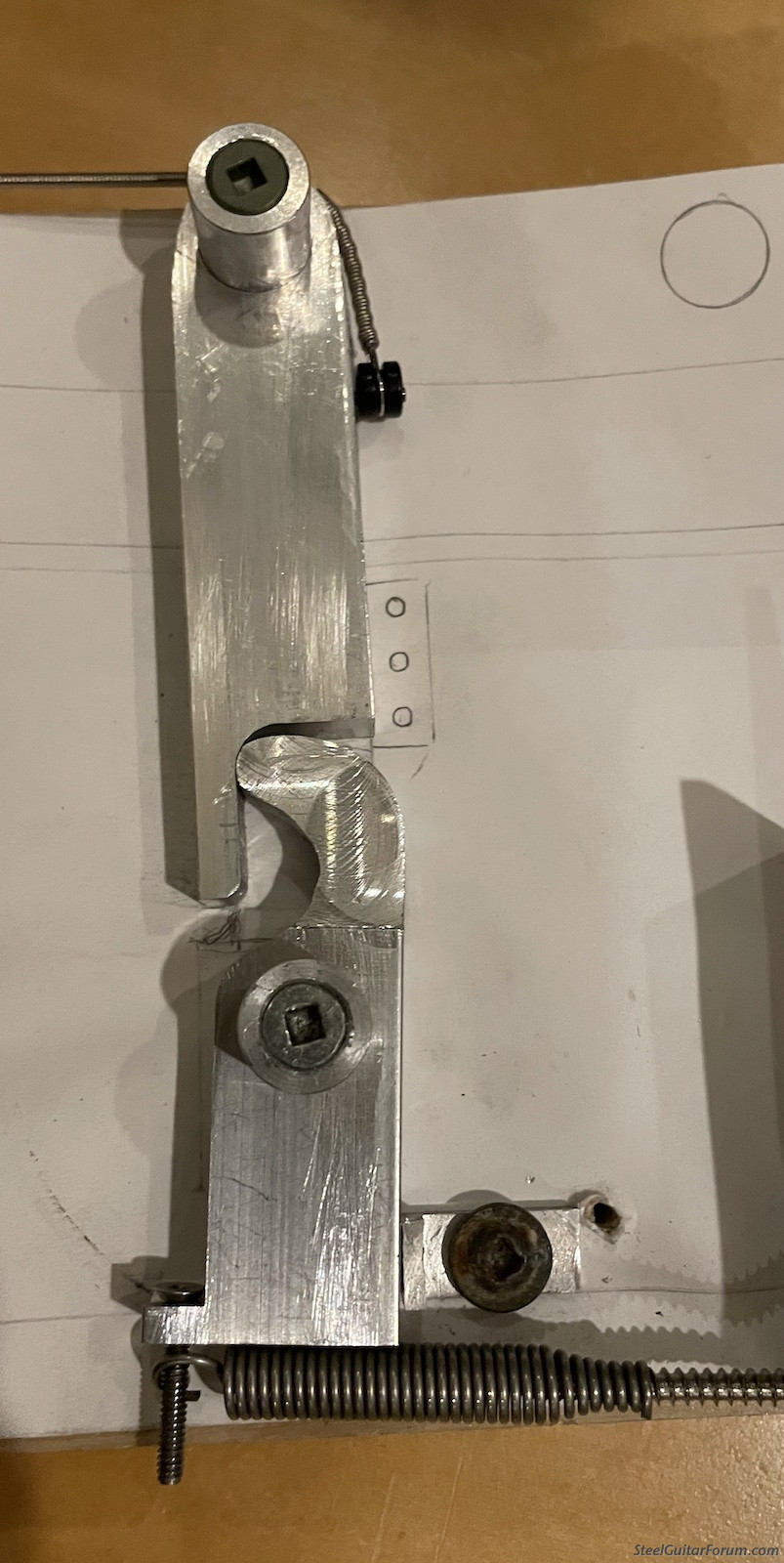

Has anybody here tried this approach that could offer me advice or words of warning?

I don't like scissor fingers because they bind up without correct adjustment so I have

been trying to come up with a way to separate out the stresses so that the raises and

lowers don't impinge or affect each other in any way.

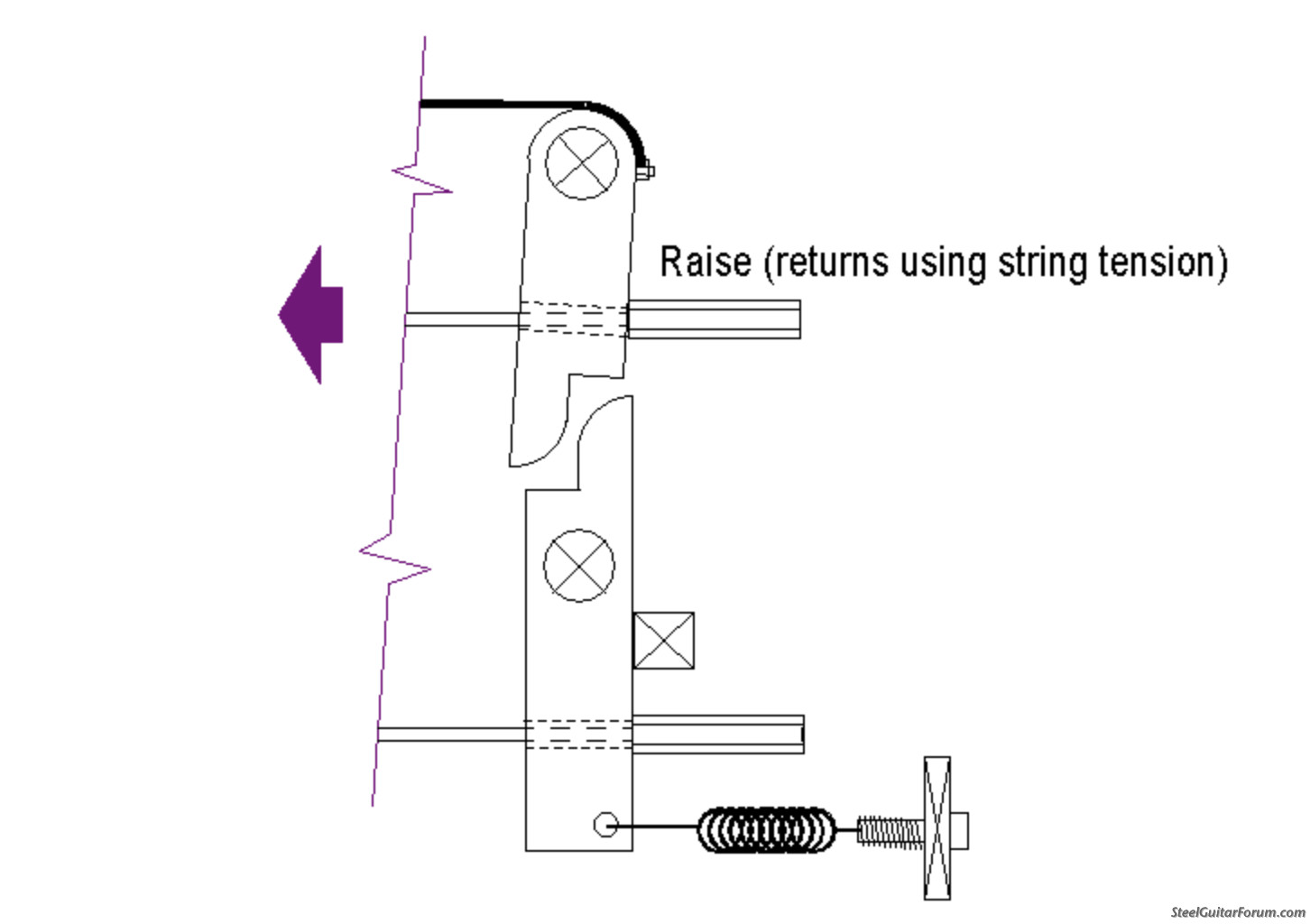

The idea is to add an axle shaft for a set of pivots lower in the endplate. This way

The springs have no effect on the raise mechanism other than to hold the lowering stop pivots. It would function like an all raise guitar unless you pull on the lowers.

It would eliminate all of the rivets and replace them with a single axle. There is a single

full width bearing surface for each string.

I can see that it might make the raises a bit harder but I'm wondering if there are any other gotchas that I have to look out for before I get stuck in on cutting the new endplate and pillow blocks.

Any ideas? |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 13 Dec 2024 12:18 pm

Posted 13 Dec 2024 12:18 pm |

|

An all-pull without a scissor.

You'd essentially loose split possibility.

On the other side, you could make it hit the pulls the body or frame, kind'a replicating the PushPull's concept on tonal re-circulation.

Someting to think about... J-D.

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|

Mike Preuss

From:

Mount Vernon, Washington, USA

|

Posted 13 Dec 2024 5:12 pm Changer

Posted 13 Dec 2024 5:12 pm Changer |

|

I have never seen a changer quite like this, and really like the inventive concept. Like JD I also see potential for ZB/Kline type tuners that stop against the endplate. I can't see any reason why it wouldn't meet or exceed your expectations.

_________________

https://www.countyrose.com/

https://www.instagram.com/changerfinger/ |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 13 Dec 2024 7:46 pm

Posted 13 Dec 2024 7:46 pm |

|

Mark Perrodin just sent me a gif of this design which is virtually the same except for the stop block position. Does anyone know who came up with this? I am curious to know how it worked out.

|

|

|

|

John Hyland

From:

South Australia

|

Posted 14 Dec 2024 1:48 pm

Posted 14 Dec 2024 1:48 pm |

|

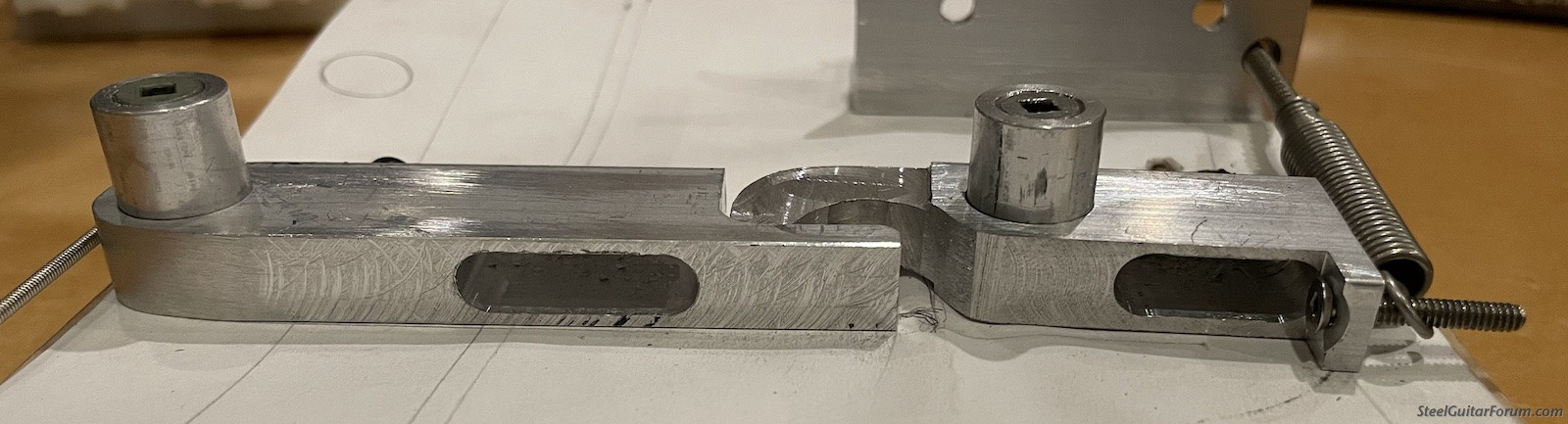

I like the hollow for the rods, making the loads all central to the strings. On my 3d printed design I have had to do this or the plastic twists. This concentric loading then became a principal design parameter for the whole pull train. That has been quite a design challenge to make sure all the pieces are capable to carry the loads and still fit in place.

I’m not sure but it looks like your design will create a very deep changer (string to lower spring)

I’m am also not sure if you are using a stop bar for the lower but if you didn’t you might be able to get split tunings but that would make for a delicate balancing act. ( maybe that is how push pulls work).

Last edited by John Hyland on 14 Dec 2024 3:58 pm; edited 1 time in total |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 14 Dec 2024 2:34 pm

Posted 14 Dec 2024 2:34 pm |

|

Yes John, What bugs me about scissor fingers is that the pulls are all off centre so they all want to twist sideways. The rivet joint is also prone to wear and twist. The whole assembly only contacts the axle for a sixteenth of an inch so it wants to swing in two directions. This creates the need for a lower comb to keep everything straight.

I am looking for a setup that wants to stay aligned rather than wanting to twist and has as few interfacing parts as possible.

Giving up tuneable splits might be the cost of this approach, but my dream is that the benefit is a guitar that is more likely to stay in tune and is easier to maintain and adjust. |

|

|

|

Bruce Zumsteg

From:

Harrisonville, Missouri, USA

|

Posted 15 Dec 2024 11:15 am

Posted 15 Dec 2024 11:15 am |

|

Les, it's good to see someone thinking of new ways to bend the strings. A friend of mine did a couple of home built guitars with that basic concept years ago, and I thought at time that it was a clever idea. If I may, I have some observations and comments, and some things you might consider.

I think that this design should come close to replicating the tone of the one piece finger changers used in the ShoBud guitars (and several others) from the late 50's, early 60's. It should be very positive and stay in tune well. However, there are several things you need to consider and test for, before you finalize your design and spend hours making parts.

The distance from the centerline of the lower axle to the the point of contact at the raise lever is very critical to the amount of KL (or pedal) travel and force that is going to be acceptable. First, use a .014 (E) note on your test board. If your configuration is satisfactory with the raises and lowers on the E, everything else will be fine. Make several different configurations of the lowering finger to find the optimum design. The trial parts can be crude and simply made, you're just looking for the final dimension.

The axle diameter for the lowering finger needs to be large enough to not deflect from the pressure of the raise fingers.

If a string is lowered and raised at the same time, the raise will dominate, so split tuning is not going to happen. Also, there will have to be slack between the raise lever and the nylon tuner in order to let the string lower to pitch (much like a push-pull or pull-release mechanism. Let us know how it turns out!

ZUM |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 15 Dec 2024 12:03 pm

Posted 15 Dec 2024 12:03 pm |

|

Thanks Bruce,

That issue with the required slack on the raise is something that I hadn't accounted for and might be a deal breaker because it might force me to swing the bell cranks further to take up the slack on the raises. I'll test as you describe and see how it works out. |

|

|

|

Rich Cottle

From:

Sacramento California

|

Posted 17 Dec 2024 11:03 am Changer

Posted 17 Dec 2024 11:03 am Changer |

|

The main problem is like JD said , your not gonna have the half stops , and that's a biggie if you know what I mean

I see two problems with your idea , for one your bottom axle is gonna have to have mounting blocks on each end and how are you gonna screw the last one in with the fingers in the way

The other problem I see is the pull rod holes have no separation , you need to drill out separate holes with a 9/64" db at the very back and the the front needs to be a slot about 3/16" "for give",

Another thing if you want the guitar to be 33",34",35"long your gonna need to put the return spring holes a couple inches toward the nut , and as far as the twist on the pull rod actuators they've been working that way for years with few complaints , your not gonna get perfect

The standard all pull system keeps a lot better tune than the push pull. why anybody would want that I'll never know (oh yeah the Emmons pp sounds great) but the changer doesn't dictate the sound , its a combination of of a lot of things , the La-Grand doesn't use the pp system and it sounds as good as the pp , this I know that the pp is guaranteed to stay out of tune

Last edited by Rich Cottle on 21 Dec 2024 7:54 am; edited 1 time in total |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 17 Dec 2024 12:18 pm

Posted 17 Dec 2024 12:18 pm |

|

Thanks Rich,

What I was thinking of doing with the axle end blocks is to mount the whole assembly with top and bottom axles to the guitar endplate using a double block at each end of the changer. I think I'll go ahead and try to build this assembly and I let you know how it turns out. Hopefully I'll make some lucky guesses and things will work out. Things do always become clearer though just as I realize that I have screwed them up   . .

I have found the scissor finger arrangement to be a bit fussy due, no doubt, to my limited manufacturing skills and I found that they could not reliably stay regulated between the house and the gig, so I got experimenting with an all raise setup and decided that I liked the sound and noticed that it was never out of tune. I feel that I need a guitar that lowers as well so I'm fiddling around with trying to find a design that has the solidity and simplicity of the all raise setup but that allows me to have lowers as well. |

|

|

|

Rich Cottle

From:

Sacramento California

|

Posted 17 Dec 2024 1:37 pm Changer

Posted 17 Dec 2024 1:37 pm Changer |

|

| Your doing this with a hack saw vise and a drill press ,arnt you ? that's gonna take a he'll of alot of work , I think you need to get some better dementions on your pivot points and there's better ways of linking the two parts together, also you really don't need a hook on your bottom finger that touches the top finger,it just needs to press against it the whole travel time , why don't you notch out the aluminum fingers for the pull rods that way you can attach the two together with a rivet and you won't need a shaft for the bottom , if it was me I would do some hard thinking and alot of testing before I went off half cocked, your ideas are not bad but the devils in the details , you need to look at how Bruce made his changer "of course I don't Bruce would tell you" , find some pictures of sho-bud ,mullens or Emmons etc.and get some more ideas , most of the guys these days are hanging the actuators from the bottom of the finger with a rivet , makes life alot easier |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 17 Dec 2024 6:55 pm

Posted 17 Dec 2024 6:55 pm |

|

| How tall is the the combination of raise and lower fingers and return spring? |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 17 Dec 2024 7:29 pm

Posted 17 Dec 2024 7:29 pm |

|

Bobby,

The distance from the top of the string to the bottom of the lower is five inches. |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 18 Dec 2024 4:44 am

Posted 18 Dec 2024 4:44 am |

|

Someone suggested the two main shafts would get in the way of the fingers. There are no scissors, they don’t get into the way of anything.

NO “combined” pulls (aka. “Splits”) possible. As soon as there is a raise, it bacomes independent of the lower. Splits would have to be “mixed” BEFORE the changer with a linkage similar to what airplanes with a V-tail had.

… JD.

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|

Rich Cottle

From:

Sacramento California

|

Posted 18 Dec 2024 9:36 am Changer

Posted 18 Dec 2024 9:36 am Changer |

|

That isn't what I said , I said that your gonna need mounting blocks for that middle shaft and its gonna be kinda cramped, you can do that but it will be pretty tricky installing it ,another thing that middle shaft doesn't need to be the same thickness as the top axle , I like the hanging fingers myself, here's a sho-bud pro one assembly "notice that they used a maverick finger and added the rest" I just put screws and nuts to hold it together. I use it for a sample

Last edited by Rich Cottle on 18 Dec 2024 11:19 am; edited 2 times in total |

|

|

|

Mike Preuss

From:

Mount Vernon, Washington, USA

|

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 18 Dec 2024 1:15 pm

Posted 18 Dec 2024 1:15 pm |

|

Hey Rich,

What is the total length of that assembly from top to bottom? |

|

|

|

Rich Cottle

From:

Sacramento California

|

Posted 19 Dec 2024 11:39 am Changert

Posted 19 Dec 2024 11:39 am Changert |

|

The total length of that bud is 4 1/2" , you'll notice that the bud has an axle and two pivot points , makes it alot easier it push , the more advanced guitars have this setup , but as you can see there's alot more work involved here , here's what I use: MSA and I make a variety (different pivot points) of them ,either way the msa is alot easier to make , I use a small band saw to cut out the steel , make sure that you use a slower speed for the steel or you'll ruin your blade ,you should be able to find an msa finger assembley here on the forum then you can redesign your own setup.

|

|

|

|