| Author |

Topic: Excel Superb Tuning Help needed! |

John Wilson

From:

Coeur d' Alene, Idaho

|

Posted 19 Oct 2024 4:30 pm

Posted 19 Oct 2024 4:30 pm |

|

Hello all.

I just received a 2010-ish Excel Superb from another forum member in a trade, and I am having a heck of a time getting my tuning to work on this new machine.

Me: I’ve been a forum member for 15+ years, been playing steel since the 70’s and have owned and worked on quite a few BMI’s, Mullens and Carters. I’m mechanically adept and build and modify if needed.

My tuning is very simple with no splits or half stops, and the problem is that I cannot Get my 8th string E to lower to a D and return (comes back flat). Simple, huh?

I have scoured the Forum for help and fixes, and nothing has seemed to help. If I can solve this one problem, I’m sure it will solve several other issues.

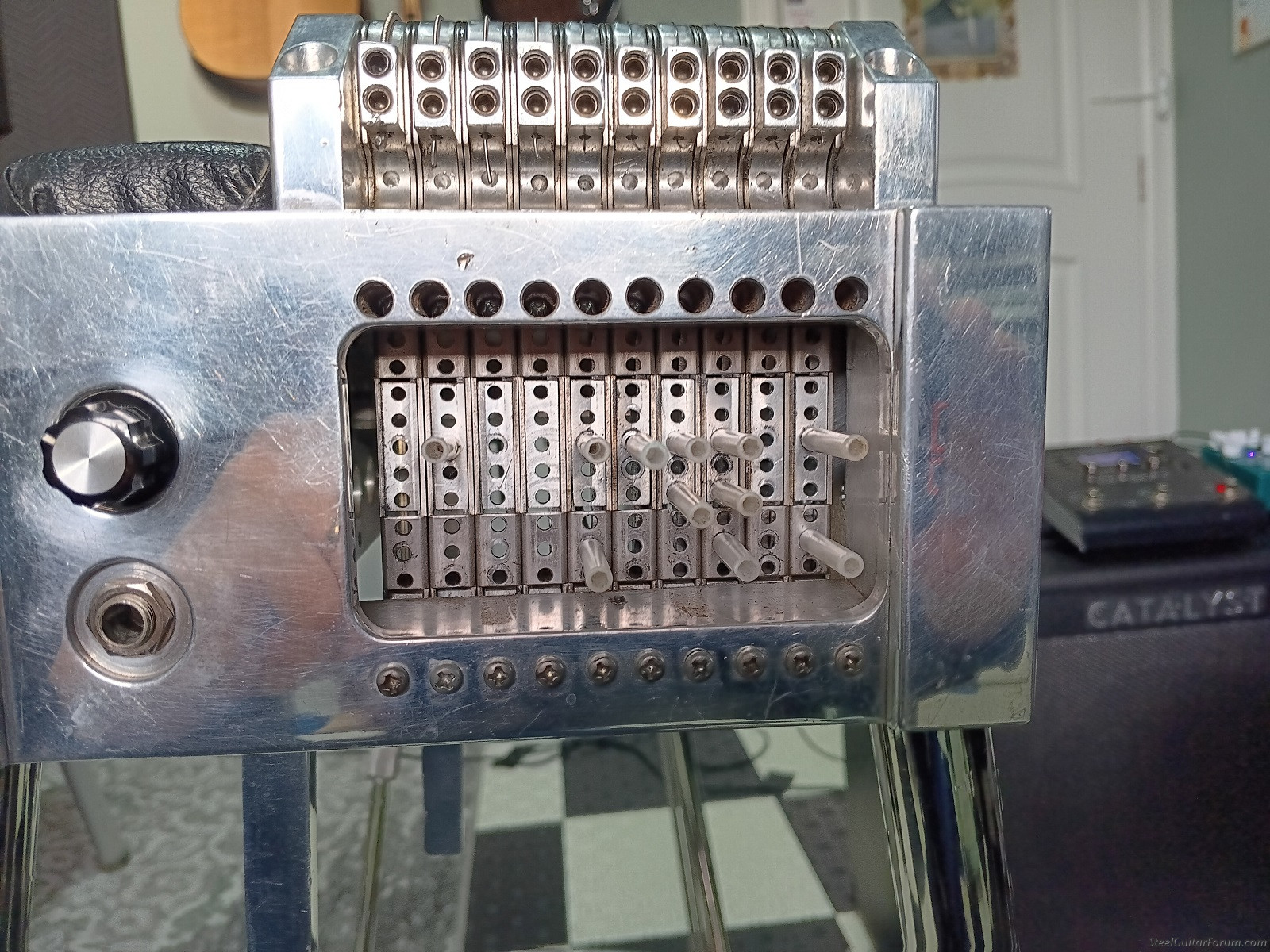

Basic PROBLEM: Can’t tune my lower E string lower to D on RKL. The issue seems to be not enough travel on the KL. Can’t adjust lever length because cap head screw stops travel (see pic #1). This is a triple raise/lower changer, right? Also, this model has the rods threaded at the hex nut and the bellcrank (with nylon threaded inserts).

Also cannot reach full D note when tuning the hex nuts at changer, un-pulled string comes back FLAT. The usual remedies (clean, lube travel chain, roller burrs, return spring, etc.) have all been tried to no avail.

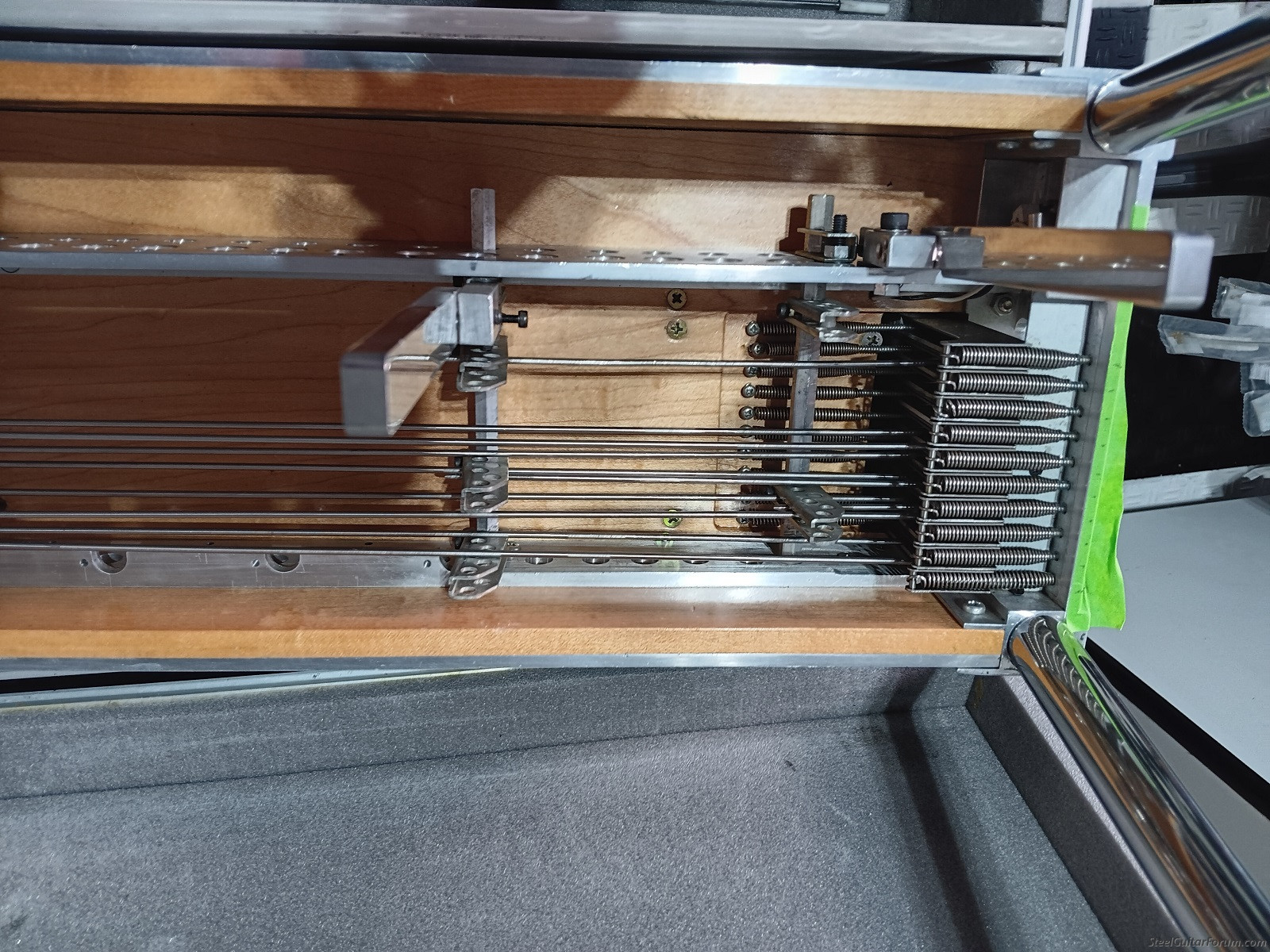

I have included pictures of the changer, underside and top of guitar. Again, I’m not using the raise or return helpers or half-stops.

Thanks guys. After about 5 hours of mucking about, I’m about ready to call it for the night.

Pic 1

Additional pics:

_________________

Customer: "Waiter, how do you prepare your chicken?"

Waiter: "We usually tell them they're not going to make it." |

|

|

|

Toshiyuki Shoji

From:

Japan

|

Posted 19 Oct 2024 7:29 pm

Posted 19 Oct 2024 7:29 pm |

|

Please know that I cannot say for sure what the cause is without seeing your instrument in person.

The causes and remedies that first came to my mind are as follows.

The maximum travel width of the Excel knee lever is determined by the contact of the Hexagon socket head cap screw with the 13 diameter hole in the rail plate.

If you want to increase the travel width of the knee lever,

Hexagon socket head cap screw must be replaced with a small head type or shaved off.

Toshiyuki

|

|

|

|

Toshiyuki Shoji

From:

Japan

|

Posted 19 Oct 2024 7:39 pm

Posted 19 Oct 2024 7:39 pm |

|

I noticed from the picture you uploaded that the changer on the first string appears to be flat, so you might want to tighten the return spring to give it more pull.

|

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 19 Oct 2024 10:58 pm

Posted 19 Oct 2024 10:58 pm |

|

I'm looking at the tuning window and at the row of screws at the top of the endplate just above the window. Are those split screws? If so, you might need to back out the screw a turn or so. That might be stopping the changer finger from lowering further.

I defer to Toshi as I'm not at all familiar with Excel guitars and those screws might not be for split tuning and perhaps serve another purpose.

Just an observation. |

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 20 Oct 2024 5:05 am

Posted 20 Oct 2024 5:05 am |

|

You've got the best resource available in Toshiyuki Shoji's participation here so that's a good thing.

I was very puzzled a while ago in an Excel discussion about that lever stop. For all the ingenuity in the design and engineering, that seems like such a limitation (but I have never had my hands-on an Excel and I may be misunderstanding things).

One point I'd like to make re: your post -- Toshiyuki Shoji has already mentioned the lower finger appearing to be depressed a little.

You say:

| Quote: |

| I’m not using the raise or return helpers or half-stops |

This makes it sound as if you are regarding the lower return springs as 'optional'. In fact, they are an essential part of the mechanism to counter the natural string tension. The lower spring must be tensioned enough to return the string to zero. Not only does this maintain consistency of tuning, it also provides a little more changer movement than if it were slightly depressed, at rest. |

|

|

|

Toshiyuki Shoji

From:

Japan

|

Posted 20 Oct 2024 7:20 am

Posted 20 Oct 2024 7:20 am |

|

In case you are not familiar with the structure of Excel's Superb Model, let me explain.

The split screw is located between the changer and the PU.

The screw above the window is the adjustment screw for the raise helper spring.

|

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 20 Oct 2024 8:38 am

Posted 20 Oct 2024 8:38 am |

|

I see. Very interesting. So no, I'm not all that familiar as I stated earlier which is why I deferred to you. Thanks for that information. Always good to learn things.

Recent innovations and the complement of rasise and lowers on these guitars is very impressive.

Looking forward to your progress with the Shoji also. |

|

|

|

Oliver Samland

From:

Hamburg, Germany

|

Posted 20 Oct 2024 8:57 am

Posted 20 Oct 2024 8:57 am |

|

Hey John,

looking the pics I notice there is no change at all installed on the 8th string of your Excel. Furthermore, it appears to me RKL is not lowering any string. Are the pics probably taken before you changed the setup? The copedent does not look familiar to me, I'm curious what the tuning is.

Anyway, on standard E9th tuning the 8th string E note is usually lowered to D#. If you got this steel in a trade, chances are the E was lowered to D#. The first thing I'd do is what Jerry and Toshiyuki suggested: back off the split tuning screws between the pickup and changer on top of the guitar. (On my Excel I "misuse" the split screw to have a more positive stop on the E lowered to D#, that way it's impossible to tune it any lower then D#.)

Ollie |

|

|

|

Larry Allen

From:

Kapaa, Kauai,Hawaii

|

Posted 20 Oct 2024 11:11 am Rkl Excel

Posted 20 Oct 2024 11:11 am Rkl Excel |

|

My Ext E9 RKL lowers 8 to E-D#-D I used a smaller hex screw and shaved off one side . Also easily tunable with slight rotation..

_________________

Excel steels & Peavey amps,Old Chevys & Motorcycles & Women on the Trashy Side |

|

|

|

John Wilson

From:

Coeur d' Alene, Idaho

|

Posted 20 Oct 2024 5:19 pm Thanks for the help.

Posted 20 Oct 2024 5:19 pm Thanks for the help. |

|

Gentlemen,

First off, thank you very much for responding to my post.

I am so thankful for the Forum and its many helpful members.

Toshiyuki: I am very excited about your attention to this post. I respect your years of involvement with the Excel line and I wish you great success in your new venture. Thank you for the picture descriptions of the split-screws, string helpers and rail-plate.

My thought regarding changing or modifying the rail cap screw is that I would use that as a last resort to increase lever throw. I know this guitar was designed to achieve a 3 raise/lower natively, so I’m looking for an adjustment related solution. That brings me to the fretboard/pickup split screw adjustors (I was not sure where those were until you explained it).

I think I am going to back off of the split screws to see if that increases throw (Thank you Jerry and Oliver!). My question is, “can I remove them entirely?”. As I mentioned in my post, my tuning has no half stops nor splits, so I view those parts as minor.

Jon: Regarding the return springs being backed off, I agree completely that they serve a purpose, but if the changer returns (unassisted)to zero after a string pull, wouldn’t it be OK to leave them untightened?

My goal would be to adjust them only if needed. Same reasoning goes for raise helper springs. (Season to taste)

Oliver: You have a sharp eye, my friend. I snapped this photo after I removed the rod pull for the 8th string. My coped is a bit unusual; it an E13 (E6/9). Kind of a modified Zane King setup I picked up from him when he introduced it a few years ago. I’ve included my coped at the bottom of this post.

Larry: Looking at the RKL and how its attached, I don’t see how I can rotate the lever to achieve more clearance. Perhaps you can elaborate? I see that it might be easier to use a shorter bolt (that runs parallel to the shaft) and move the clamp mechanism closer to the center of the guitar thus clearing the rail.

Again, thank you for the responses. I will work with what you’ve given me and report back.

God bless.

John

_________________

Customer: "Waiter, how do you prepare your chicken?"

Waiter: "We usually tell them they're not going to make it." |

|

|

|

Larry Allen

From:

Kapaa, Kauai,Hawaii

|

Posted 20 Oct 2024 7:16 pm Excel

Posted 20 Oct 2024 7:16 pm Excel |

|

Aloha John, I rotate the Screw (Not the Lever) that I shaved one side of, it comes out kind of egg shaped and can be rotated to increase or reduce the throw. Guitar upside down on bench, shave one side of the screw, reinstall, put Allen wrench on it and engage the RKL and dial it in (if you have the rod and bell crank adjustments done for the correct throw).

_________________

Excel steels & Peavey amps,Old Chevys & Motorcycles & Women on the Trashy Side |

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 21 Oct 2024 4:53 am Re: Thanks for the help.

Posted 21 Oct 2024 4:53 am Re: Thanks for the help. |

|

| John Wilson wrote: |

Jon: ..... wouldn’t it be OK to leave them untightened?

My goal would be to adjust them only if needed. Same reasoning goes for raise helper springs. (Season to taste)

|

Here's my take, John. A lower will not return to pitch without a return spring. In other words, if it returns, it is the spring that is returning it. In fact if you remove the spring the lower finger just lets go. So the spring is in play, always. How much tension is the question.

The correct amount of spring tension is: enough to return to pitch from a lower and enough to ensure that a raise on the same string causes no movement of the lower finger. After that, there are some other things you can factor in for a little extra finesse but 'just enough' is usually just enough. When I set it up I give it enough tension to return the lower and hold the lower finger during the raise .... and then a titch more. But it is essential to use your eyes for this task, not your ears.

If a lower returns to accurate pitch but the finger is visibly off the stops, at rest, then you are leaving room for inconsistency of open pitch and very likely allowing movement of the lower finger during a raise which again, while possible to seem to tune up ok, is a recipe for inconsistency. |

|

|

|

John Wilson

From:

Coeur d' Alene, Idaho

|

Posted 27 Oct 2024 2:10 pm The good, and the bad...........

Posted 27 Oct 2024 2:10 pm The good, and the bad........... |

|

Hello all,

I have spent the last week adjusting and modifying per the excellent suggestions here on the forum, and I wanted to report my (mixed) results.

I modified the RKL lever (rail) set screw to increase lever throw (grinding it down per Toshiyukis suggestion), REMOVED the split screw bolts on the top of the guitar, and completely backed off of the raise helper screws. I was still not able to achieve the 8th string E-D drop I was shooting for.

The nylon nut at the end overtightens if I try to tune down to the D note (on the KL pull) and the unaffected string comes back flat. (This is classic over-tuning per Jon Lights excellent sticky at the top of this post section.)

The problem is that the tuning is done at the nylon barrel of the bellcrank, and I cannot introduce “slack” that is needed to solve the problem.

In addition, this over tuning mucks with my other ½ step raises and lowers on the same string.

My final solution was a compromise; I changed my tuning, and moved the D pull to the 9th string open, which allowed the other E to D# and E to F pulls to operate sufficiently. Not great but workable.

A question I have asked my self is whether there is a problem with my changer, as the raise finger would sometimes pull when lowering the 8th string. I have lubricated, blown out and lubricated the changer twice to minimize this possibility. Changer dis-assembly is not an option at this time.

There were 3 other string pulls that suffered from variations of the same over-tuning issue, and I was able to solve 2 of them by carefully adjusting the (very delicate) balance of open tuning, nylon nut tuning, and return spring tightening to allow them to play within acceptable tolerance.

The final over-tune issue is my 1st string (3rd on standard tuning) and I ran into the same string break issue many have reported with that .011” string. I ended up using .10’s for now until my reinforced 11’s come from the Forum store. The first string will still not fully tune down to G from G#, but it is only a few cents off so I’ll live with it.

I’ve included a picture so there is a documentation of what the raise-helper and return springs look like.

I’ve also included a pic of the changer end with the split-lowering holes of the changer fingers. My question is, why not have all the lowers adjacent as opposed to split between the raise holes. Leverage?

In conclusion, once adjusted, the raise lower action is very smooth, and I love it, but it appears that (barring “changer” issues), this is one temperamental beast to tune. I’m left questioning whether this guitar is actually a triple raise/lower changer as reported, or simply a 2 up, 2 down. I can’t get within a mile of achieving a 1-1/2 tone raise or lower.

Please feel to chip in with any additional thoughts or suggestions, and I will give them a try.

As for now, I will continue with this crazy love-hate relationship. I’ve been married for 35+ years so I have some experience with how to handle stuff like this.

Thank you all and God Bless.

John

_________________

Customer: "Waiter, how do you prepare your chicken?"

Waiter: "We usually tell them they're not going to make it." |

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 27 Oct 2024 2:37 pm

Posted 27 Oct 2024 2:37 pm |

|

Hoo boy. When design & engineering has enough differences from steel guitars with which I am familiar, it makes me regret having opened my mouth to begin with. This should be the province of people who know this specific machine.

One thing I'll mention, at least as it pertains to general all-pull design, is the situation of long lowers such as E > D which can be challenging on some guitars and can present the issue of lowering just so far and then the raise finger starting to engage.

The needs of the long lower can lead you to want to hook into the changer hole with max ratio leverage (the hole closest to the changer axle). This can get into a whole complicated relationship between the location of the pulling rod, the location of the lower return spring, and the amount of tension of that spring. A super-tight return spring can move or refocus the fulcrum point. And the different possible locations of the rod/hole are another moving data point in this set of equations.

On a Sho-Bud (without adjustable springs) I had to select a changer hole that challenged my sense of 'obvious' hole selection in order to get the whole step lower (and only just barely). The higher-leverage hole was much more prone to cause the raise finger to move.

Now....with the notion the 'split' locations of lower finger holes on this Excel.....I'm just dizzy trying to wrap my head around the implications of that, in the context of the rest of this post. |

|

|

|

John Wilson

From:

Coeur d' Alene, Idaho

|

Posted 27 Oct 2024 2:44 pm Physics can be fun!

Posted 27 Oct 2024 2:44 pm Physics can be fun! |

|

Hey Jon.

Thanks for the reply.

Yes., this has certainly been a learning experience. I didn't post this, but I tried numerous hole combos at bell crank and changer, just trying to fine-tune a result.

Hopefully, I'll wake up at 2 AM one night and it will hit me (?).

J.

_________________

Customer: "Waiter, how do you prepare your chicken?"

Waiter: "We usually tell them they're not going to make it." |

|

|

|

Larry Allen

From:

Kapaa, Kauai,Hawaii

|

Posted 27 Oct 2024 3:32 pm Excel

Posted 27 Oct 2024 3:32 pm Excel |

|

Aloha John. This is what my copeds look like on my 2010 Excel Superb S10.. RKL lower both 4 & 8 E-D#-D. I tried all the combinations until I got the setup..

_________________

Excel steels & Peavey amps,Old Chevys & Motorcycles & Women on the Trashy Side |

|

|

|

Oliver Samland

From:

Hamburg, Germany

|

Posted 27 Oct 2024 3:45 pm

Posted 27 Oct 2024 3:45 pm |

|

Hey John,

Interesting that you mention your string break issue on your 1st string G# to A. I use 0.12th on my Excel's 3rd string (G# to A) with no problem, never broke that string. That lead me to the question: is your's probably one of the long scale Excel's? I remember he offered 2 different scale length at one point, maybe he still does. If physics apply, on a long scale you'd need a longer throw than on a short scale for lowering a string 2 semitones (or any change), given the hardware parts are the same.

Are your 1st strings breaking at the same point, like nut or changer?

I remember reading several threads about a weak batch of 0.11th gauged strings of a particular brand that escaped me, these got posted just a few weeks ago. That's probably unrelated to your issue, but as it happened just recently I'll throw it in here.

Ollie |

|

|

|

John Wilson

From:

Coeur d' Alene, Idaho

|

Posted 27 Oct 2024 4:29 pm Thanks for replying

Posted 27 Oct 2024 4:29 pm Thanks for replying |

|

Larry,

I tried multiple hole combos at changer and bellcrank, still could not get the desired result. Your bottom 6 strings are the same as my tuning (before I changed the D to 9th string). I'm guessing you have a shorter scale (than 25.5") guitar.

Oliver.

Yes, this steel is a longer 25.5" scale which requires more string tension. There is a whole 'nother thread on the forum about people snapping their #3 string on this model/length guitar. Various solutions were offered; I settled on .11 reinforced strings.

Thanks,

John

_________________

Customer: "Waiter, how do you prepare your chicken?"

Waiter: "We usually tell them they're not going to make it." |

|

|

|

Larry Allen

From:

Kapaa, Kauai,Hawaii

|

Posted 27 Oct 2024 4:41 pm Excel

Posted 27 Oct 2024 4:41 pm Excel |

|

This Excel is 25.5” ..pics are RKL..I’ve also used a .012 on 3rd string for over 30 years on several Excels, long and short scales..

_________________

Excel steels & Peavey amps,Old Chevys & Motorcycles & Women on the Trashy Side |

|

|

|

Toshiyuki Shoji

From:

Japan

|

Posted 28 Oct 2024 1:21 am

Posted 28 Oct 2024 1:21 am |

|

I've been thinking about this a lot and the causes that came to mind, but first I want you to know that your steel guitar was manufactured long before I started working at Excel and is a very early model of the Superb model.

This means that Mitsuo was also in a period of considerable trial and error.

Can you show me a close-up image of the area I circled in red on the photo?

Play the 8th string and push the lower finger with the tip of a Phillips screwdriver. The pitch should go down, but does it go down from E to D?

If the pitch is not lowered sufficiently, then either the changer does not have the capability to lower the pitch from E to D in the first place, or there is another cause.

Maybe there is not enough clearance between the changer and the area where the split tuning resides, which I call the changer holder wall.

Toshiyuki

|

|

|

|

Marshall Woodall

From:

New York, USA

|

Posted 28 Oct 2024 4:26 pm

Posted 28 Oct 2024 4:26 pm |

|

| Just chiming in as a proud owner of one of Larry's old Superbs. That 8th string should be capable of at least a whole tone drop by maximizing your leverage and the aforementioned screw head grinding to increase the travel. One thing you did not mention is whether or not you tried to rotate the bell crank around its shaft to give you the tuning advantage you need. because you have those older style plastic threaded bell crank inserts you will undoubtedly have to rotate things to give you more room to play with at the changer. Maybe the actual pull rod needs more threads or was originally meant for another pull altogether? I prefer the unthreaded barrel/set screw scenario (in the bell crank hole) because that eliminates all the finagling. I hope I'm making sense(?) |

|

|

|

Toshiyuki Shoji

From:

Japan

|

Posted 28 Oct 2024 4:50 pm

Posted 28 Oct 2024 4:50 pm |

|

The amount of pitch change is greater when the position of the bellcrank hole where the barrel is inserted is farther away from the cross shaft.

|

|

|

|

Larry Allen

From:

Kapaa, Kauai,Hawaii

|

Posted 29 Oct 2024 12:37 pm Excel

Posted 29 Oct 2024 12:37 pm Excel |

|

Change out the plastic bell crank rod holders with the metal/set screw types, simplifies the tuning options. I got a lot of them from Mitsuo and made a few dozen in my shop and converted several excels ..

_________________

Excel steels & Peavey amps,Old Chevys & Motorcycles & Women on the Trashy Side |

|

|

|

Justin Shaw

From:

Ontario, Canada

|

Posted 29 Oct 2024 2:32 pm

Posted 29 Oct 2024 2:32 pm |

|

| Is is possible for someone to post a step by step guide of how to install a change and then tune it on one of these guitars? Mine is from a few years ago and I'm still not sure I'm doing things right. Even in this thread it doesn't seem clear to me what the process is or should be. |

|

|

|

Larry Allen

From:

Kapaa, Kauai,Hawaii

|

Posted 29 Oct 2024 4:45 pm Excel

Posted 29 Oct 2024 4:45 pm Excel |

|

John did you get the 4 page manual for your guitar? If not I can send you one (email). Larry

_________________

Excel steels & Peavey amps,Old Chevys & Motorcycles & Women on the Trashy Side |

|

|

|