| Author |

Topic: Electro Pedal Steel Build |

Jacobus De Bruyn

From:

NSW, Australia

|

Posted 5 Apr 2024 2:29 am

Posted 5 Apr 2024 2:29 am |

|

Good morning.

I announce my new project in January this year when I started working on it. I thought its time for an update.

Progress is slow but surely going forward. There however were some challenges to overcome from my originally Wishlist.

My Wishlist.

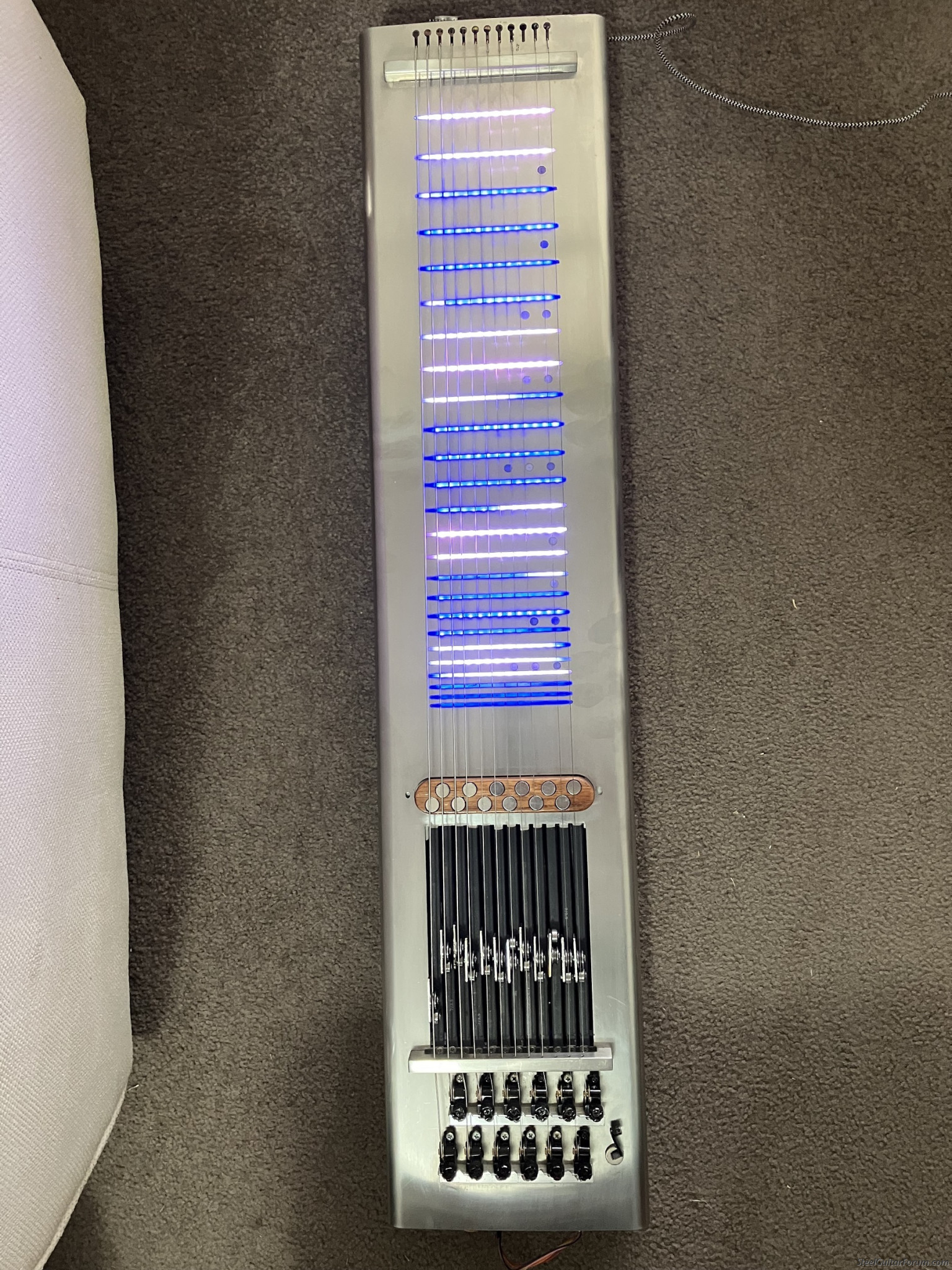

1) Guitar will have a stainless steel body which is laser cut. (Done)

2) The guitar will not have tuning pegs at the nut side but instead it will be tuned at the bridge. Done.

Strings will be adjusted with three methods.

a) Manually by finger. Done.

b) Manually using a small handle to wind, it's faster.

c) Auto tuning where the guitar will tune itself in auto tune mode. This will be a completely new concept. I already done some tests and it does work. Code 50% done.

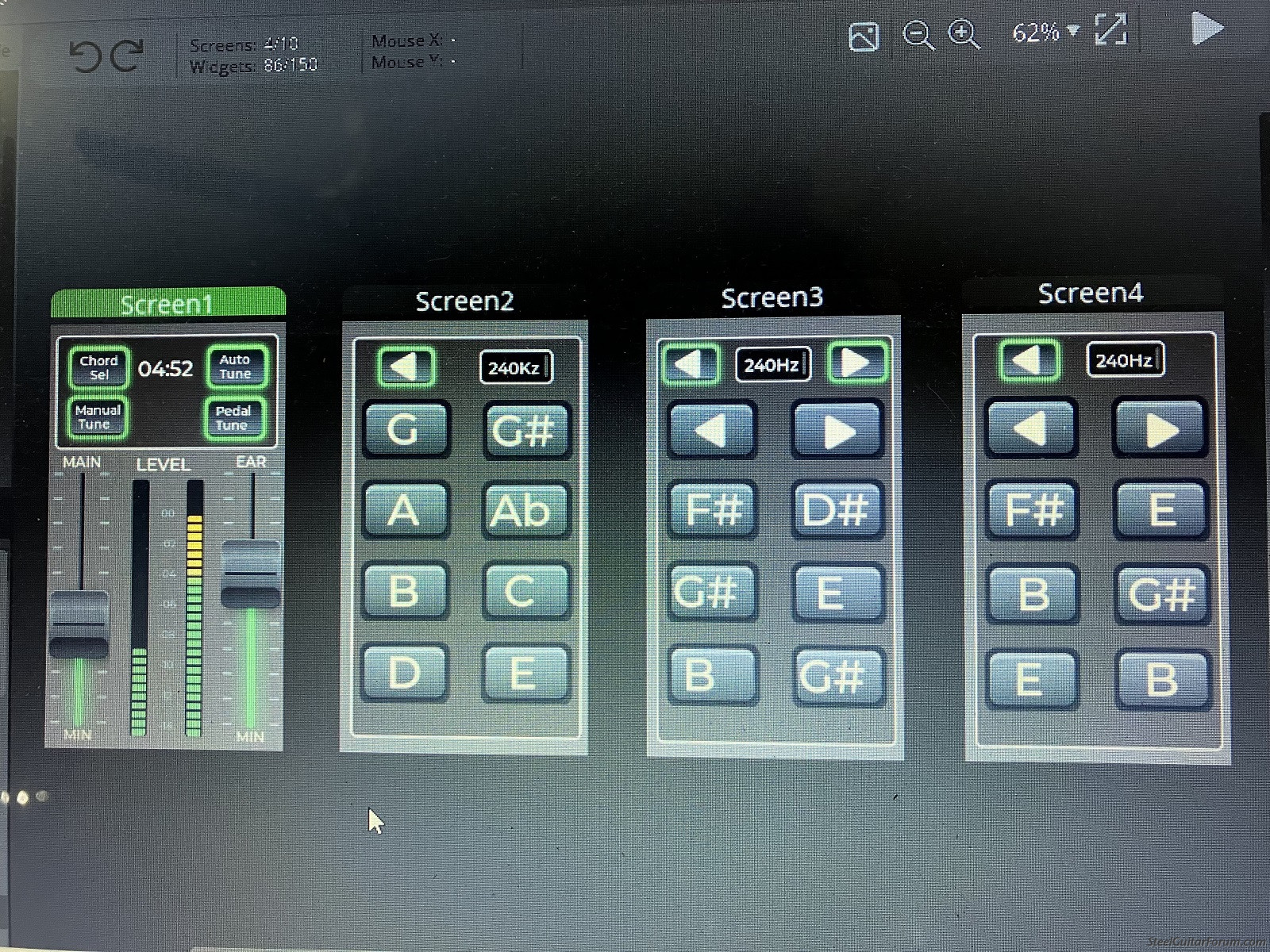

3) The Guitar will have a touchscreen display, which will house all controls for tuning, chord select, changing from E9 to C6 and more. Touch screens done. Screenshot Attached.

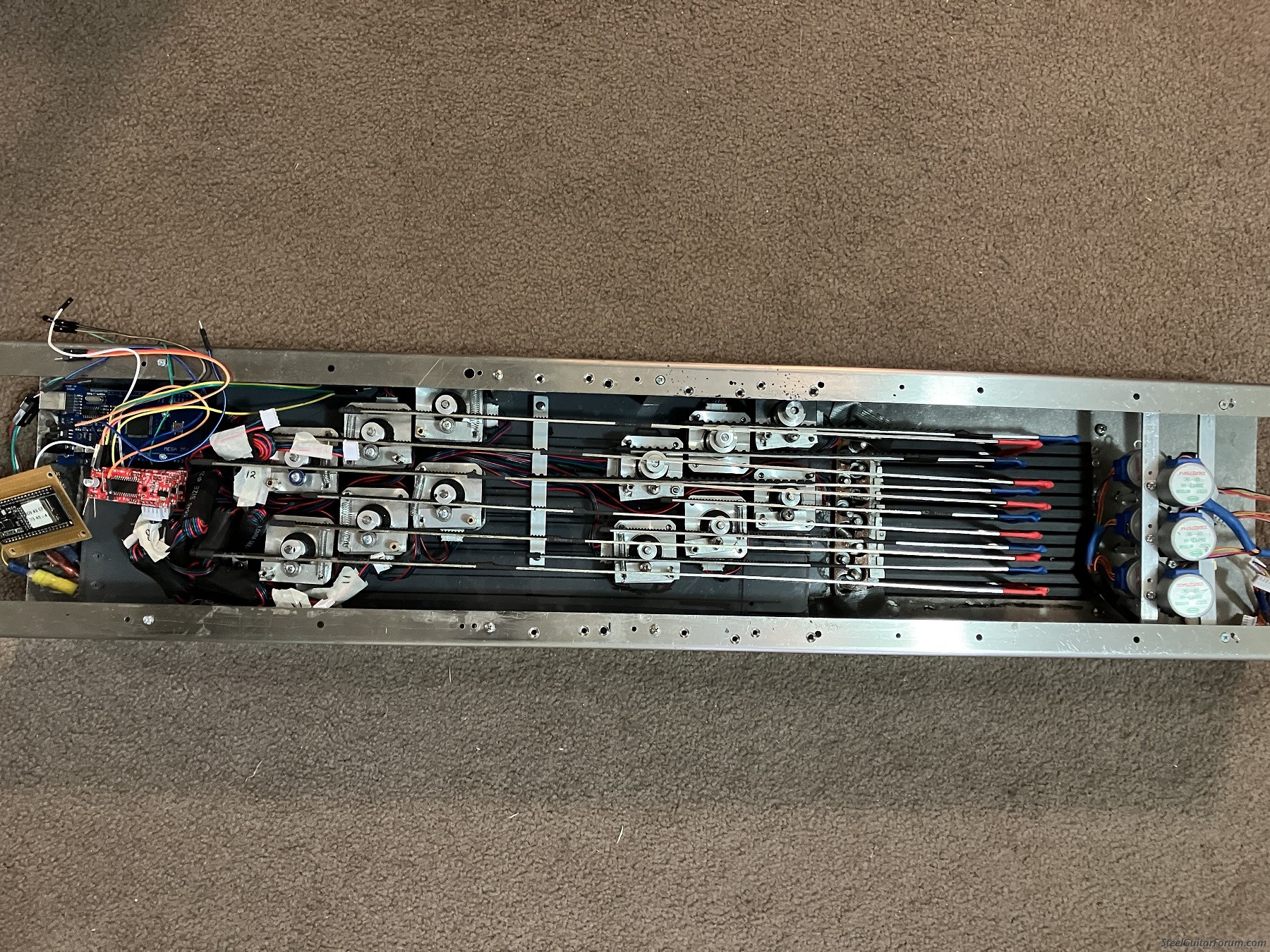

4) This design will use stepper motors. installation completed.

5) With this design the strings will not be stretching to change the pitch. More later on.

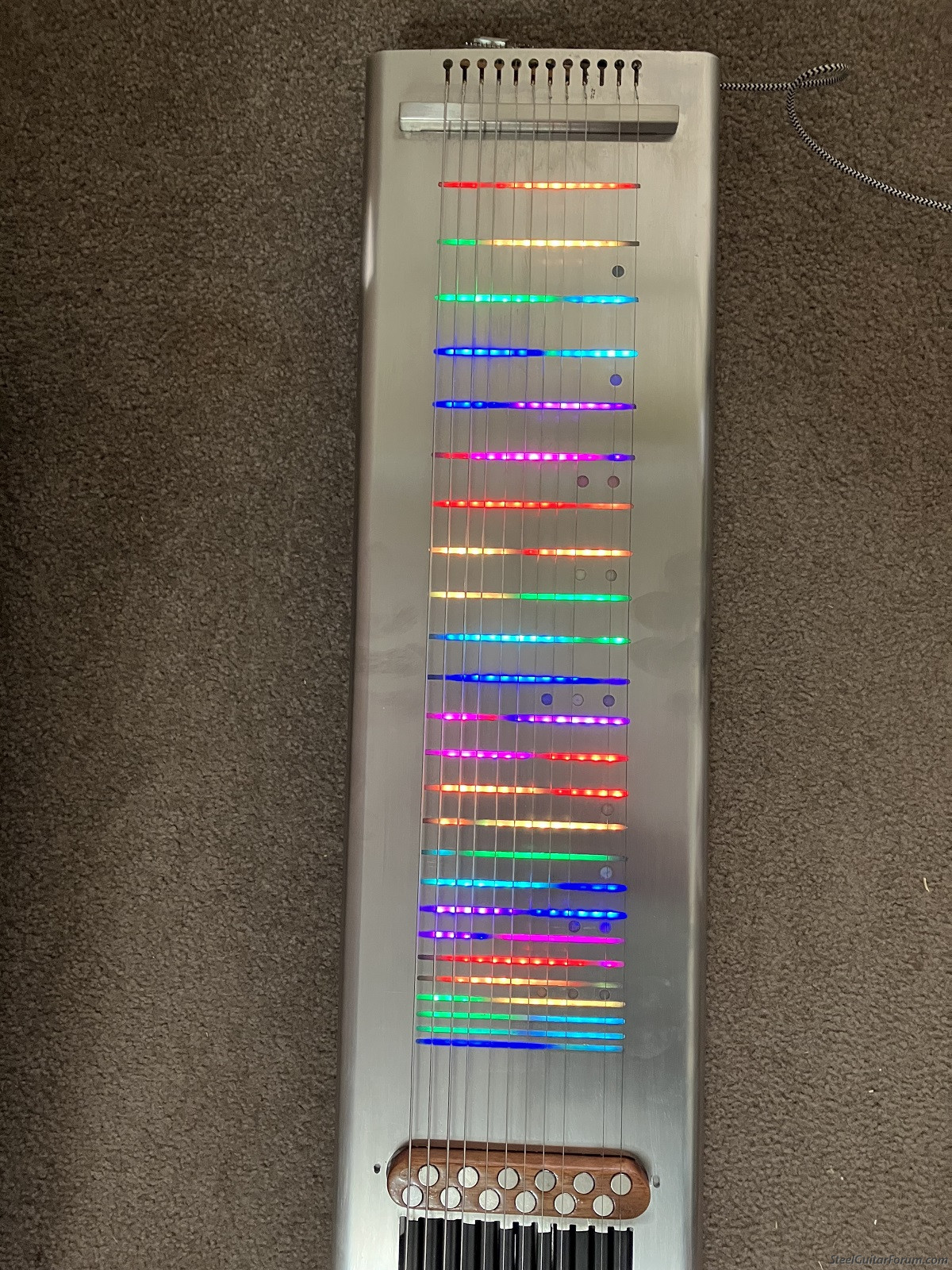

6) The fret on the fret board on this build will be lit up in any colour, selected in the parameter list. Done see pictures.

7) The fret on the fret board will also be used as follow. When you play for example in "G" when you select "G" in the touch screen the corresponding frets will change to a different color. That will be useful when playing in the dark, or when in training or just because it looks nice. Done

8)Pedals A, B, C, D, and E will use "Hull sensors". My first build used potentiometers. Fone.

9) The communication from the pedals to the main panel will be wireless, as it is on the first build. Done

10) The guitar will be able to convert to C6 from the display. Code in progress.

11) The guitar will have a wireless headphones. Not done yet

12) The speaker outlet will be wireless as well. Not done yet

13) The head and tail will be rounded off with a dark wood finish, where the touch screen will be fitted at the top of the head stock.

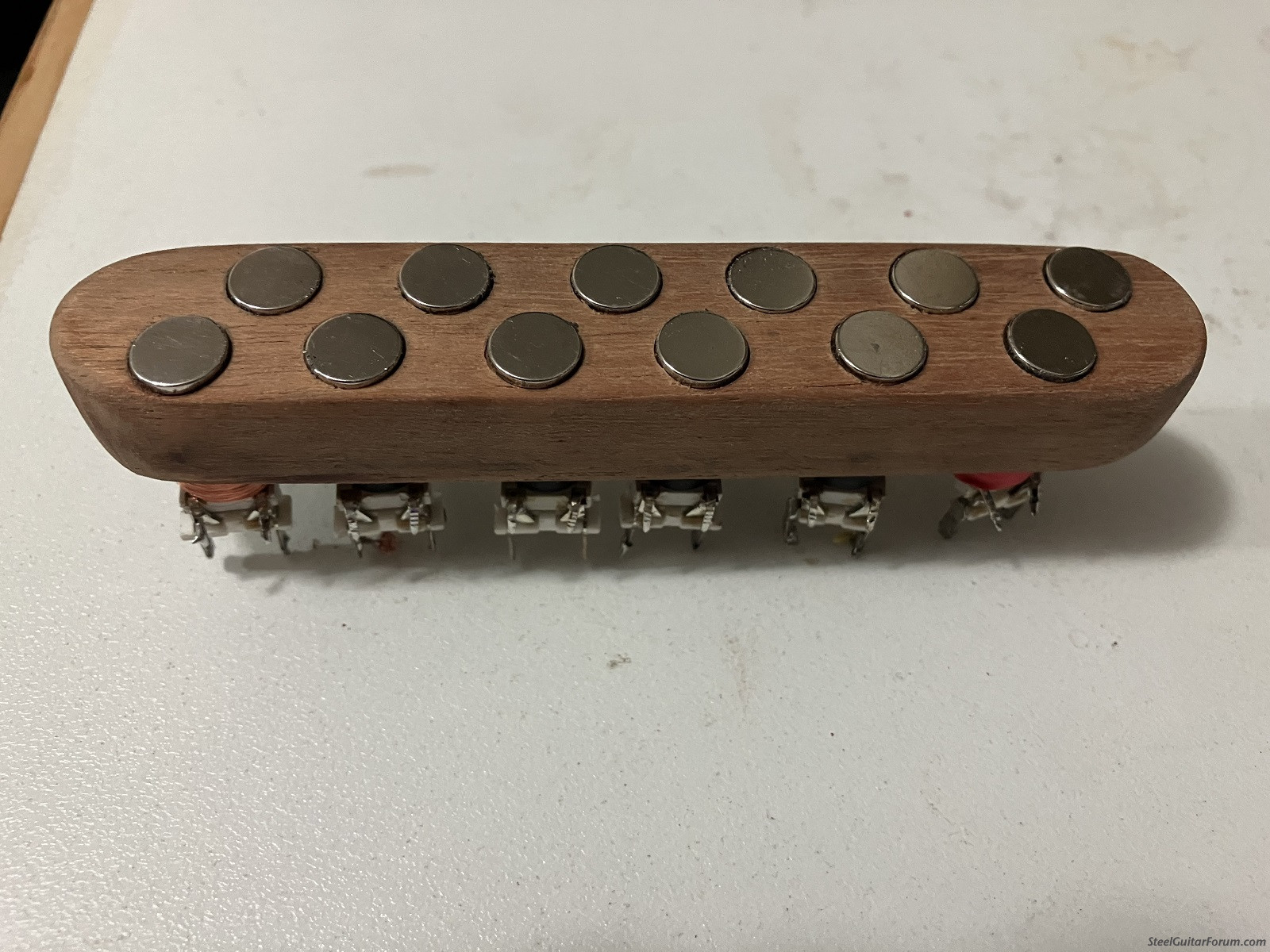

The pick-up already done with wood. It came out quite nice.

13) To achieve the auto tuning I had to create a multi wind pick-up. One coil per string. Done.

Most of the code was tested before, but all need to be compiled into a functional setup and tested. Meaning there is still lots of hours to be spend before completion.

The code up to now did give me some major issues, but I'm getting there slowly but surely.

On the hardware side a couple of you had concerns about when I move the string cage that the fret bars will be offset. I originally did not realize it, but it however will be the case. So, the plan is when all is running, I will take measurements and electronically via the software compensate for the offset. I'm confident that I can correct it via the code.

|

|

|

|

Al Carey

From:

Dublin, NH USA

|

Posted 10 Apr 2024 1:59 am

Posted 10 Apr 2024 1:59 am |

|

This is truly fascinating. Bravo!

_________________

Sierra U-12, Gretsch 6120, Fender Tele, old tube amps, etc... |

|

|

|

Jacobus De Bruyn

From:

NSW, Australia

|

Posted 12 May 2024 12:08 am Electro Steel Guitar Progress

Posted 12 May 2024 12:08 am Electro Steel Guitar Progress |

|

I thought I will give a brief progress before I slow down a bit with the built. The Guitar as it is currently is about 50-60% complete. There is unfortunately a however in the works as I struggle to get some things done.

The body and mechanical assembly went as planned but the part I struggle with, I might need to seek help.

The code to control the stepper motors currently give me problems as it just refuse to do wat is asked. I'm sure it is in the code so will work on it. I'm new to Code standards so still learning by error.

The sound and sustain also do not currently meet the steel guitar standards and will need some modification to get it up to standard.

Attach some photos up to where I am today. Last photo with my 3 Steels. Lap, first built and current.

|

|

|

|

Carl Mayer

From:

Richmond, Virginia, USA

|

Posted 13 Jun 2024 5:20 am

Posted 13 Jun 2024 5:20 am |

|

Im glad to see the progress youre making on this! I had a couple more questions if you dont mind elaborating.

What are your mechanical tuning machines? is that something store bought or did you scratch build them? I havents seen anything like those but it makes for a nice compact setup.

For your changer, from the pictures it looks like youre just adjusting the scale length instead of the tension, wont that mess up your intonation (like if you have a perfectly tuned change in open position, the same change with the bar at the 12th wont be in tune because youre no longer at the center point the strings you adjusted the scale for), or is the movement small enough its negligible?

On your first build how did you do the tuning without the touchscreen interface you have in the second build? was it stable enough you just program the servo rotations once and you dont really need to mess with it after that? or did you have some trimmer pots hidden somewhere for tuning?

_________________

————————-

-1930 Bacon and Day tenor banjo

-a whole lot of homemade nonsense |

|

|

|

Jacobus De Bruyn

From:

NSW, Australia

|

Posted 14 Jun 2024 1:36 pm Electro Steel second build

Posted 14 Jun 2024 1:36 pm Electro Steel second build |

|

On the tuner I heavily modified an existing tuner, If you punch in the following in ebay you will see what I used as a baseline(6 String Headless Guitar Bridge Tailpiece for Electric Guitar Parts).

On the changer side of things, yes as the tuner carts move the strings do go out of tune but I compensate that in the code. As you move the metal bar moves over the strings I measure between any string (same as on a touch screen) and that determine the compensate value. That work well, However...

The however is on the sound quality through the tuning carts. I lose quality and cannot get the genuine steel guitar pitch.

I am in the proses in making the call to maybe dump the carts and go back to the tuning fingers. I designed the buddy such that it can be changed.

On my first build the tuning are done manually as on a normal guitar. The string pitch changing are done by servo motors and program. |

|

|

|

Carl Mayer

From:

Richmond, Virginia, USA

|

Posted 15 Jun 2024 7:48 pm

Posted 15 Jun 2024 7:48 pm |

|

Yeah I’m speculating but I can imagine you loosing a lot of sustain and high end with the way the strings are supported if I’m looking at your pics correctly. Your string trolleys are held up on just strips of the sheet metal body(what looks like ~5mmWx1mmHx100mmL beams), those are going to be orders of magnitude more compliant than a regular ~15mm changer axle. That means more string energy is directed towards moving those beams up and down and not towards keeping the strings ringing a long time. It also looks like you have some black plastic for the trolleys to slide on, if that’s even a little soft/rubbery you’re going to loose energy there too(especially in the high end). Before you give up on the design and go back to a rotating changer you could try replacing or adding more rigid support under the trolleys and see if it helps. Or just as a test put a solid bar under all the strings as a temporary rigid bridge (to eliminate the changer) and see if you’re satisfied with the tone. if the sound quality is still not acceptable maybe the problem isn’t the changer but some other component altogether (like the single string pickups, the nut, etc)

_________________

————————-

-1930 Bacon and Day tenor banjo

-a whole lot of homemade nonsense |

|

|

|

Jacobus De Bruyn

From:

NSW, Australia

|

Posted 16 Jun 2024 12:02 am Electro Steel second build

Posted 16 Jun 2024 12:02 am Electro Steel second build |

|

Hi Carl. Yes your ideas are all valid and I did worked through it all. I did removed the plastic slewing and put more support at the bottom of the rails. I might take you on to add more support at the bottom and see how it go. On the pick-up side, I wound a single pick-up with 16K resistance which I use on my first build.

I am thinking more towards the trolley as there are too many touch points. (top pulley, top pulley bearing, lower pulley, lower bearing, the support bars and finally the metal that flex to the sides for support). That whole area needs to be solid.

Thanks for your support I will test it with a solid when I'm back home and see how it go. |

|

|

|

Jacobus De Bruyn

From:

NSW, Australia

|

Posted 22 Aug 2024 1:38 pm The perfect pitch / frequency

Posted 22 Aug 2024 1:38 pm The perfect pitch / frequency |

|

| Hi all. I am in the process to conclude my project and will sent a progress soon. As all the controls are done by software which needs calibration I need the following from you experienced. What is the perfect pitch for a 12string E9 and a C6 10 string. Also I need the values for the foot and knee levers. The reason for the 10 strings for C6 is when selecting C6 the system will adjust 10 strings and disable the top 2. I will be using a universal setup (suggestions on which setup will all be tested.). |

|

|

|