| Author |

Topic: tool to make square shaft end round? |

Tim Toberer

From:

Nebraska, USA

|

Posted 1 Mar 2023 10:31 am

Posted 1 Mar 2023 10:31 am |

|

| I realize you could do this on a lathe, but is there a easier faster way? Something on a drill press maybe? |

|

|

|

Richard Sinkler

From:

aka: Rusty Strings -- Missoula, Montana

|

Posted 1 Mar 2023 10:51 am

Posted 1 Mar 2023 10:51 am |

|

Check out this video from Fulawka.

https://www.youtube.com/watch?v=jS16EEzN-3Q

_________________

Carter D10 8p/8k, Dekley S10 3p/4k C6 setup,Regal RD40 Dobro, Recording King Professional Dobro, NV400, NV112,Ibanez Gio guitar, Epiphone SG Special (open D slide guitar) . Playing for 54 years and still counting. |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 1 Mar 2023 5:49 pm

Posted 1 Mar 2023 5:49 pm |

|

You would need an annular cutter and a good drill press with enough clearance for a clamping setup. I have been trying this myself with mixed results on being able to get a true alignment on both ends of the cross shaft I am cutting.

You need a vice on a drill press table that can hold the shaft exactly perpendicular to the cutter. The vice should have perpendicular V grooves to hold the square stock.

I would not buy a cheap cutter online for this because it is the inside measure which is critical. I had to go the store with callipers and measure each cutter to find an American tool with the 5/16" inner diameter. The asian ones I got on Amazon were a complete bust.

Another thing to watch out for is that annular cutters typical need a 3/4" chuck.

The main problem I have had is that a drill press is not easily adjustable for precise alignment and my drill press is a general purpose tool in my shop. Fulawka had more drill presses than a cat hoarder has scratches so he set up his cutter in a dedicated permanent setup.

I am thinking that I might be better off to do this using my lathe mill combo and a V block for clamping, chucking the cutter in the lathe and using the cross table to push the workpiece into it. I'll let you know how it works out. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 2 Mar 2023 6:07 am

Posted 2 Mar 2023 6:07 am |

|

What a great video, you could spend years with him and still learn. Not many people like him around anymore... |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 2 Mar 2023 6:14 am

Posted 2 Mar 2023 6:14 am |

|

| Les Ford wrote: |

Fulawka had more drill presses than a cat hoarder has scratches so he set up his cutter in a dedicated permanent setup.

|

Keep me posted, looks tricky! Keep me posted, looks tricky! |

|

|

|

Les Ford

From:

British Columbia, Canada

|

Posted 2 Mar 2023 8:31 am

Posted 2 Mar 2023 8:31 am |

|

| Tim Toberer wrote: |

| Les Ford wrote: |

Fulawka had more drill presses than a cat hoarder has scratches so he set up his cutter in a dedicated permanent setup.

|

Keep me posted, looks tricky! Keep me posted, looks tricky! |

You can see in the video clip that Fulawka used a very solid drill press with a fixed, non-tilting table so he was guaranteed perpendicularity.

I think that his first operation on the other drill press is just to knock off the corners to make it easier for it to self centre and start into the annular cutter in the second operation. |

|

|

|

Wayne Brown

From:

Bassano, Alberta, Canada

|

Posted 3 Mar 2023 3:29 pm steel guitar

Posted 3 Mar 2023 3:29 pm steel guitar |

|

Ed was a great builder and innovator.

_________________

Owner Out West Music,Seats,Parts and accessories

www.outwestcountry.ca |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 3 Mar 2023 8:21 pm

Posted 3 Mar 2023 8:21 pm |

|

Setting up to do that would be expensive to buy the tooling to set up, The way shown in the Video. The cheapest tool to make the end round pointed round on a square rod, Would cost 69.00. For a tool to put a round section on the square rod, 228.00 for a 1/4" Annular cutter to make the round end, On the internet.

Add that to a good heavy built drill press and a good vice would be very expensive to put round ends on 12 cross rods.

I noticed in the video he had to take the cross rod to another tool like a grinder with a special wheel to give the rod a bearing fit shine too.

Getting a smooth bearing fit on the cross rod end would be the thing I would worry most about.

Another thing to consider, Attaching the cross rod in the guitar, And be able to remove it if needed during building, Set up, or work on later would be important.

If you have a local gunsmith or repair shop that could do lathe work at a reasonable charge, May be a cheaper way to go. |

|

|

|

Per Berner

From:

Skovde, Sweden

|

Posted 3 Mar 2023 11:09 pm

Posted 3 Mar 2023 11:09 pm |

|

What about cutting the square cross shafts a little shorter, drilling and tapping a hole in each end (quite long ones, to be safe), and then bolting on pieces of polished round stock? Would not require much in the way of tools and would be pretty quick – and strong enough.

If you should happen to drill the holes a tiny bit off center – that would not be a problem, since we are talking about very small circular movements, not rotation. |

|

|

|

Ian Worley

From:

Sacramento, CA

|

Posted 4 Mar 2023 11:18 am

Posted 4 Mar 2023 11:18 am |

|

| Per Berner wrote: |

What about cutting the square cross shafts a little shorter, drilling and tapping a hole in each end (quite long ones, to be safe), and then bolting on pieces of polished round stock? Would not require much in the way of tools and would be pretty quick – and strong enough.

If you should happen to drill the holes a tiny bit off center – that would not be a problem, since we are talking about very small circular movements, not rotation. |

That's how BMI does it, they use 'fillister head' screws with a high profile head and a smooth outer surface. 10-32 thread has a head diameter of 5/16". The shafts (or bars in BMI's case) mount in pre-drilled holes on the rear aluminum apron. The screws back out through the mounting holes to remove the shafts, but it would work fine to mount the shafts on L brackets inside the apron too. For a longer mounting surface a better choice would be smooth face SS cap screw like in the pic at the bottom, they have a taller head than a fillister head screw. Bonus feature to this approach is that the end bearing surface can be replaced if it starts to wear.

https://www.mcmaster.com/90332A126/

_________________

All lies and jest, still a man hears what he wants to hear and disregards the rest - Paul Simon |

|

|

|

Ian Worley

From:

Sacramento, CA

|

Posted 4 Mar 2023 11:52 am

Posted 4 Mar 2023 11:52 am |

|

| Bobby D. Jones wrote: |

Setting up to do that would be expensive to buy the tooling to set up, The way shown in the Video. The cheapest tool to make the end round pointed round on a square rod, Would cost 69.00. For a tool to put a round section on the square rod, 228.00 for a 1/4" Annular cutter to make the round end, On the internet.

Add that to a good heavy built drill press and a good vice would be very expensive to put round ends on 12 cross rods... |

Annular cutters are also called 'hollow cutters', I have one that cost about $35 for the cutter and mandrel, it's not as deep as the one in Les' pic. It also cuts slightly under size, ~.002"-.003". It cuts a really nice circular slot (what it's meant for), but not super clean on the interior when used like this, still requires a little hand work. I actually used mine in the tail stock of the lathe, but you could easily make a jig for the vise to center and align the shafts consistently on a drill press table. I still found it preferable to do it the old fashioned way on the lathe, it's only about 1-2 minutes per end with cleaner results.

That said, IMO the stainless cap screw method above is the better approach.

_________________

All lies and jest, still a man hears what he wants to hear and disregards the rest - Paul Simon |

|

|

|

Chris Lucker

From:

Los Angeles, California USA

|

Posted 4 Mar 2023 12:22 pm

Posted 4 Mar 2023 12:22 pm |

|

Or do as MCI or EMCI and use steel square tubing with round dowels fixed with set screws. Easily adjustable when installing and removing.

_________________

Chris Lucker

Red Bellies, Bigsbys and a lot of other guitars. |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 4 Mar 2023 10:29 pm

Posted 4 Mar 2023 10:29 pm |

|

A lot would depend on how the guitar side rails are in the guitar. And how the rods go in and out. The MSA classic plate on back apron, Or bearing plates that screw to inside of aprons is easy way.

I have been thinking about this post, And a cure.

A lathe with a 4 jaw chuck would be the easiest and quickest.

There is a way to drill a perfect aligned hole in a rod or pipe on a drill press. I will draw it out take a picture and post it. May take me a day.

I figured this out to drill a ML Pistol Barrel to thread and put a Breech Plug in. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 5 Mar 2023 7:43 am

Posted 5 Mar 2023 7:43 am |

|

These are great ideas! Thankfully I already have a 4 jaw self centering chuck in my metal lathe cause I used to do a lot of wood spindle turning. So turning boring etc. not an issue. In the end it all takes time. Turning them down is tedious, but may be the simplest for me. I really like the tapping in a cylindrical head screw idea. 10-32 seems small, but I guess it must be enough. It is good to not overbuild these things, cause weight and space can become an issue obviously.

I really don't want to invest in a bunch of new tooling, I am trying to be more of a minimalist because hopefully soon I will be moving my shop and I am unsure how much space I will have. Thanks again. |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 6 Mar 2023 5:35 pm

Posted 6 Mar 2023 5:35 pm |

|

This is a way to align a hole drilled in the end of a rod, square or hex shaft. With a solid bracket hooked to the drill press column aligned with the drill chuck works. This is just a demo on a small table press. I have to go to a friend and use his big drill press. With the hole in a bracket below the table aligned straight with the drill press chuck makes a true straight hole, From centered punch in center of shaft being drilled. If using a heavy table top press that the head could be slid down the column would work like this too.

Make the hole in bottom bracket so shaft is just aligned, It is gripped in vise for drilling. |

|

|

|

Sonny Jenkins

From:

Texas Masonic Retirement Center,,,Arlington Tx

|

Posted 9 Mar 2023 5:12 pm

Posted 9 Mar 2023 5:12 pm |

|

| Drill 1/8 hole into the end (centered) about 1",,,,drive 1/8" rod into end. It's not like it will be rotating @ 3500 rpm,,,maybe 8-10 degrees max. Use the KISS approach. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 13 Mar 2023 6:17 am

Posted 13 Mar 2023 6:17 am |

|

| Sonny Jenkins wrote: |

| Drill 1/8 hole into the end (centered) about 1",,,,drive 1/8" rod into end. It's not like it will be rotating @ 3500 rpm,,,maybe 8-10 degrees max. Use the KISS approach. |

I like this idea, I don't see why it wouldn't work. I am considering this cause the idea of turning these all down feels oppressive. I will probably use 3/16" cause 1/8" seems a little wimpy. Only one way to find out. Thanks for the idea! |

|

|

|

Sonny Jenkins

From:

Texas Masonic Retirement Center,,,Arlington Tx

|

Posted 14 Mar 2023 3:01 am

Posted 14 Mar 2023 3:01 am |

|

1/8 ss rod sticking out a quarter inch won't be wimpy. A lot of other things would bend or break before that would. KISS,,,,Avoid overkill

TIP,,,but not necessary! If you drill small hole in crossroad at the bottom of the 1/8 hole it would allow air to escape and make the driving in of the rod easier. If you clean the hole with acetone and use JB weld as lubricant the 1/8 rod would become essentially an integral part of the cross rod. Again,,,not necessary,,,avoid overkill. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 14 Mar 2023 6:11 am

Posted 14 Mar 2023 6:11 am |

|

| Sonny Jenkins wrote: |

1/8 ss rod sticking out a quarter inch won't be wimpy. A lot of other things would bend or break before that would. KISS,,,,Avoid overkill

TIP,,,but not necessary! If you drill small hole in crossroad at the bottom of the 1/8 hole it would allow air to escape and make the driving in of the rod easier. If you clean the hole with acetone and use JB weld as lubricant the 1/8 rod would become essentially an integral part of the cross rod. Again,,,not necessary,,,avoid overkill. |

Ok I trust you Sonny. Great idea! Why make things more difficult than they already are. |

|

|

|

LaVern Skarzenski

From:

North East,Pennsylvania, USA

|

Posted 14 Mar 2023 3:14 pm Square Cross shaft rounding tool

Posted 14 Mar 2023 3:14 pm Square Cross shaft rounding tool |

|

Back in Jan. 2011 the old Steel guitar builders forum had a good discussion on this operation and a few pictures. Mike Farmer provide the pictures and explanation. Here is a link http://steelguitarbuilder.com/forum/viewtopic.php?f=4&t=453&p=3466#p3466. I don't know if it will work anymore. It worked for me. Back in Jan. 2011 the old Steel guitar builders forum had a good discussion on this operation and a few pictures. Mike Farmer provide the pictures and explanation. Here is a link http://steelguitarbuilder.com/forum/viewtopic.php?f=4&t=453&p=3466#p3466. I don't know if it will work anymore. It worked for me.

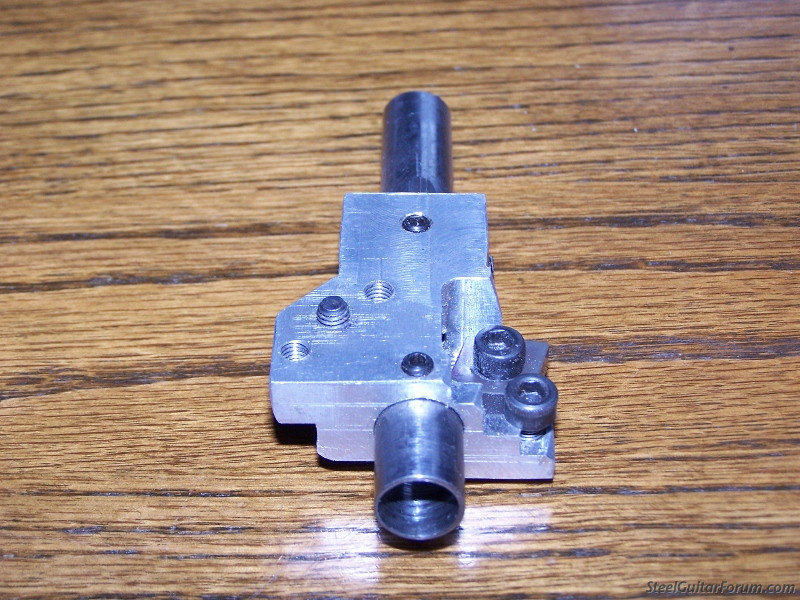

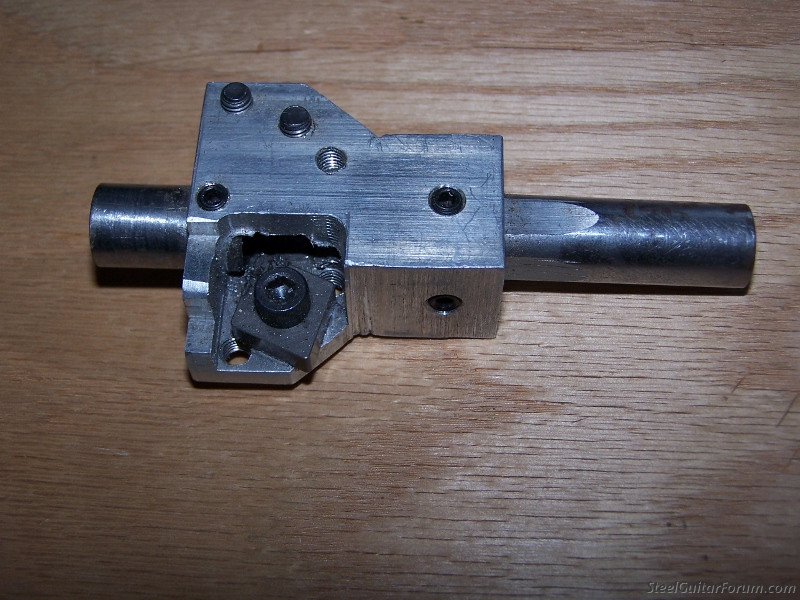

The way it works is the right end of the tool as shown in the second picture gets chucked up in a drill press or maybe even a hand held drill while the square shaft is put into the hollow shafton the left side. The shaft must be secured in a vise so it won't rotate and as the tool is turned the diamond shaped insert turns around the shaft removing material. Like a lathe except the tool turns instead of the part. You can see the hollow shaft in the top picture. To adjust the final diameter the insert is loosened and rotated clocwise to decrease diameter, counter clockwise to get a larger diameter. Hope this helps someone.

LaVern

_________________

GFI S10, BSG S10, Nashville 112, Digitech 155, DOD DFX9 Digital Delay, Goodrich L 120. |

|

|

|

LaVern Skarzenski

From:

North East,Pennsylvania, USA

|

Posted 15 Mar 2023 4:29 pm Turning square cross shafts

Posted 15 Mar 2023 4:29 pm Turning square cross shafts |

|

Gee guys,

I didn't mean to kill the conversation.

LaVern

_________________

GFI S10, BSG S10, Nashville 112, Digitech 155, DOD DFX9 Digital Delay, Goodrich L 120. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 16 Mar 2023 6:44 am Re: Turning square cross shafts

Posted 16 Mar 2023 6:44 am Re: Turning square cross shafts |

|

| LaVern Skarzenski wrote: |

Gee guys,

I didn't mean to kill the conversation.

LaVern |

Sometimes it takes people a while to digest. When I first asked the question I was envisioning something almost exactly like this. Time will tell, but is seems like overkill to design troubleshoot and build this tool. If it works, which I am sure it does, it may be worth it, but I can just see myself beating my head against a wall trying to build this thing. Some people have more skill with these things, real machinists. I am feeling pretty confident about Sonny's idea. I would rather be building guitars than jigs. Thanks for posting this though, I am sure someone will find it useful. Its all just grist for the mill  |

|

|

|

Mike Preuss

From:

Mount Vernon, Washington, USA

|

Posted 16 Mar 2023 7:46 am Turning Square Cross shafts

Posted 16 Mar 2023 7:46 am Turning Square Cross shafts |

|

I have been following this thread closely. Lots of good ideas shared. Laverne, your tool is pretty neat and very similar to a tenon cutter used in log furniture construction. I used hexagonal rod for the guitar I am currently building since I can simply put it in the chuck of my drill press and file the ends round. Probably not the best method, but this thread didn't exist when I started!

I am not sure which method I will use when I get around to building another guitar. I am always striving for a balance of efficiency and quality within the constraints of my very limited tool set. This builders corner is a great resource to help with that objective, that's for sure. |

|

|

|

LaVern Skarzenski

From:

North East,Pennsylvania, USA

|

Posted 16 Mar 2023 9:20 am

Posted 16 Mar 2023 9:20 am |

|

| Tim Toberer wrote: |

| These are great ideas! Thankfully I already have a 4 jaw self centering chuck in my metal lathe ......cause I u will have. Thanks again. |

I don't think you'll find any easier and faster way to turn these down if you already have a 4 jaw, self centering chuck on a metal lathe. I guess I should have read all the post more carefully. I agree the machining of this tool would involve some careful machining and unless you are planning on building more than one guitar it may be overkill.

LaVern

_________________

GFI S10, BSG S10, Nashville 112, Digitech 155, DOD DFX9 Digital Delay, Goodrich L 120. |

|

|

|

Mike Farmer

From:

Indiana, USA

|

Posted 16 Mar 2023 8:24 pm Tool

Posted 16 Mar 2023 8:24 pm Tool |

|

I was the one that made the tool at the bottom of the page. At the time I didn't want to spend a lot of money on ready made expense tools. I worked in a factory where I could get some ideas from tools that were there... The key that makes this tool work is the piece that is hollow,it is just big enough for a 5/16 square piece will just fit inside it.. In the case with this design is with 2 inserts and 4 tips that can be used. If you have what they call a "hollow mill" when it gets dull you have to find someone to sharpen it. Somewhere in that post is a picture of a piece of a square

shaft that I turned down. It works best in a drill press and a good vice. Just trying to help out.... |

|

|

|