| Author |

Topic: Help! Broken part on my new pedal steel! |

Brandon Stanek

From:

Minnesota, USA

|

Posted 12 Feb 2019 4:35 pm

Posted 12 Feb 2019 4:35 pm |

|

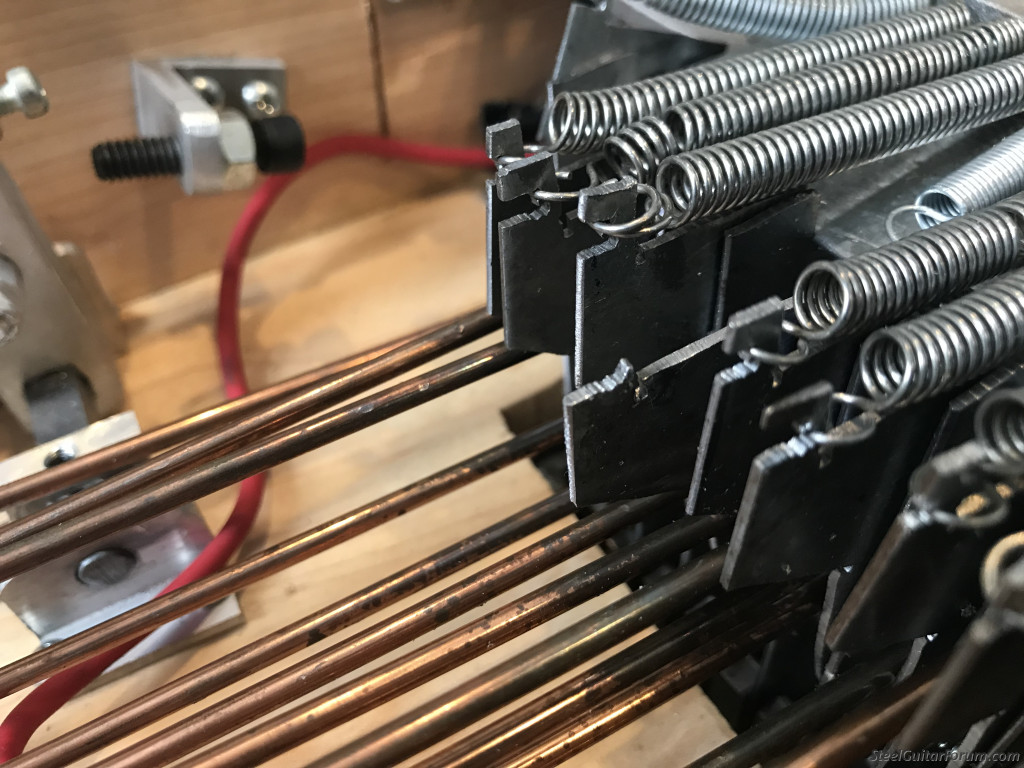

Hello everyone! I’m new to the forum and playing pedal steel. I just picked up a Wilcox 3x4 a few weeks ago. This is my first pedal steel guitar and I need some help with a problem that came up today.

I was replacing a spring and when I tried to hook it to the metal piece (I don’t even know what it’s actually called) it snapped off! Now my middle pedal is unusable! Just wondering if anyone had some advice on how to fix or replace this part. I’ve attached a couple pictures to help explain. I appreciate your help. Thanks!

|

|

|

|

Dom Franco

From:

Beaverton, OR, 97007

|

Posted 12 Feb 2019 6:09 pm

Posted 12 Feb 2019 6:09 pm |

|

The slots where the springs hook into look all roughly filed or hack-sawed (Jury rigged) by a previous owner. Perhaps homemade changer parts... You could just cut another slot in the broken piece or replace the whole part. (it looks like a cheap sheet metal piece that any local machine shop could fabricate for you) They usually are reasonable priced if you ask nicely.

_________________

https://www.youtube.com/channel/UCYG9cvwCPKuXpGofziPNieA/feed?activity_view=3 |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 12 Feb 2019 6:52 pm

Posted 12 Feb 2019 6:52 pm |

|

Sorry to be the bearer of bad news. The pulling fingers in that guitar are terrible, probably the worst I've seen. I don't know if that's standard Wilcox work, or someone else tried to make the parts. From the looks of it, other fingers are close to failing from the same problem. What you really need is a new changer or one from another guitar. What you have could be fixed, but it would require removing the changer, and then some re-engineering and repair to make it like it should be. Since you're new to steel guitar, I wouldn't advise you to try to fix it yourself. You need an experienced builder/repairman to give you an estimate.

I'm so sorry you bought that guitar. Do you have any recourse or former business relationship with the seller? |

|

|

|

Darvin Willhoite

From:

Roxton, Tx. USA

|

Posted 12 Feb 2019 7:54 pm

Posted 12 Feb 2019 7:54 pm |

|

A hole could be drilled under that raggedy slot, then the spring hooked into the hole. The end of the spring may need a coil or two cut off of it so you only have one coil to hook into the hole. Of course the changer would have to be totally dis-assembled to do this.

_________________

Darvin Willhoite

MSA Millennium, Legend, and Studio Pro, Reese's restored Universal Direction guitar, a restored MSA Classic SS, several amps, new and old, and a Kemper Powerhead that I am really liking. Also a Zum D10, a Mullen RP, and a restored Rose S10, named the "Blue Bird". Also, I have acquired and restored the plexiglass D10 MSA Classic that was built as a demo in the early '70s. I also have a '74 lacquer P/P, with wood necks, and a showroom condition Sho-Bud Super Pro. |

|

|

|

Bob Carlucci

From:

Candor, New York, USA

|

Posted 12 Feb 2019 8:07 pm

Posted 12 Feb 2019 8:07 pm |

|

If it were mine, it would go to a good local welder that knows what he's doing.. A small piece of flat stock of similar thickness could be welded on in a few minutes.. Just have the welder look at how the fingers work so he makes sure there is no interference with other fingers.. Probably cost peanuts to fix...

that is some awful workmanship. I have no idea how it got that way, but a wilcox isn't worth putting a lot of money into. They are not highly regarded by most players.

I would simply have that one finger welded up so the spring can be refastened. and then play the hell out of it.. bob

_________________

I'm over the hill and hittin'rocks on the way down!

no gear list for me.. you don't have the time...... |

|

|

|

richard burton

From:

Britain

|

Posted 12 Feb 2019 10:04 pm

Posted 12 Feb 2019 10:04 pm |

|

You might be able to do the job in situ.

Get a small hacksaw and cut a small groove (marked in red)

Make a small wire loop and hook one end to the spring and the other end to the new groove

|

|

|

|

Mike Scaggs

From:

Nashville, TN

|

Posted 13 Feb 2019 3:19 am

Posted 13 Feb 2019 3:19 am |

|

| Bob Carlucci wrote: |

If it were mine, it would go to a good local welder that knows what he's doing.. A small piece of flat stock of similar thickness could be welded on in a few minutes.. Just have the welder look at how the fingers work so he makes sure there is no interference with other fingers.. Probably cost peanuts to fix...

that is some awful workmanship. I have no idea how it got that way, but a wilcox isn't worth putting a lot of money into. They are not highly regarded by most players.

I would simply have that one finger welded up so the spring can be refastened. and then play the hell out of it.. bob |

If it were mine (and its not) I would do exactly what Bob said and pull the changer and repair the finger properly or replace it if possible. That can be TIG welded easily and finished off. Would also be a good time to cleanup the changer as well. This is very fixable but not without some work. Mickey Adams can get this done too if you don't want to tackle it yourself (just a thought). Good Luck

_________________

I can explain it to you but I can't understand it for you

Zum double Hybrid 8x9, 64 Twin (JBLs), p2pAmps Bad-Dawg, p2pAmps Tremendous Reverb, Visit my website www.p2pamps.com |

|

|

|

Richard Stoops

From:

Ohio, USA

|

Posted 13 Feb 2019 5:51 am broken steel guitar part

Posted 13 Feb 2019 5:51 am broken steel guitar part |

|

I had a Wilcox 3X5 and the changer fingers didn't look anything like the one's here. The work on mine was excellent. I would try to find either another changer or a complete set of fingers. Changers come up on the forum from time to time. My Wilcox played and sounded good, so yours probably will too after it is repaired. Also now would be a good time for other maintenance to be done.

_________________

Emmons and Rittenberry Steel guitars plus assorted 6 string guitars |

|

|

|

Ronnie Boettcher

From:

Brunswick Ohio, USA

|

Posted 13 Feb 2019 7:45 am

Posted 13 Feb 2019 7:45 am |

|

If you have some tools, and a drill, I would go to a hardware store, or a home depot. In the electrical department get a 4" square box cover. That should be big enough to cut a new piece. Hacksaw, files, dremel tool. Take a good one out, for a pattern, and make one. Or take your changer out, and swap the bad one with you 10th string one, then mickey mouse the bad one, like said earlier, by cutting a groove into it. You do not get that much use out of the 10th string. it is worth a try. The blank 4" box cover is less than one dollar. Worth a try. Good luck.

_________________

Sho-Bud LDG, Martin D28, Ome trilogy 5 string banjo, Ibanez 4-string bass, dobro, fiddle, and a tubal cain. Life Member of AFM local 142 |

|

|

|

Brandon Stanek

From:

Minnesota, USA

|

Posted 13 Feb 2019 8:51 am

Posted 13 Feb 2019 8:51 am |

|

Thanks for all the responses and ideas! I greatly appreciate it. I have a friend who welds for a living that is going to attempt to TIG weld it before I try anything else.

Really disappointing to hear about the poor quality on this Wilcox. Are changer fingers somewhat universal or are there certain things I should be aware of? I assume if I wanted to go that route I would be better off changing all fingers, not just the problem one. Where would I begin to look for them? Thanks again everyone! |

|

|

|

Jack Hanson

From:

San Luis Valley, USA

|

Posted 13 Feb 2019 8:51 am

Posted 13 Feb 2019 8:51 am |

|

| If you're anywhere near the Twin Cities, it may be worth contacting Clem Schmitz. Send me a personal message for contact info if you need it. |

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 13 Feb 2019 8:58 am

Posted 13 Feb 2019 8:58 am |

|

| Brandon Stanek wrote: |

Thanks for all the responses and ideas! I greatly appreciate it. I have a friend who welds for a living that is going to attempt to TIG weld it before I try anything else.

Really disappointing to hear about the poor quality on this Wilcox. Are changer fingers somewhat universal or are there certain things I should be aware of? I assume if I wanted to go that route I would be better off changing all fingers, not just the problem one. Where would I begin to look for them? Thanks again everyone! |

Too bad about your issue Brandon. Sorry to hear it. Anyway, there appears to be enough room there to just scab on another piece of steel, assuming the original part is steel and not aluminum. That's what I'd probably do. Drill a couple holes in the existing finger and a repair piece and bolt them together. If your friend has another idea with the welder, that may be better.

Far as changers go, I believe they are all specific to a given instrument. Since Chet has passed on, probably not going to find any changer parts for that guitar.

I'd probably just attempt a repair on that scissors finger and get back to playing. |

|

|

|

Bob Carlucci

From:

Candor, New York, USA

|

Posted 13 Feb 2019 9:17 am

Posted 13 Feb 2019 9:17 am |

|

what Jerry said.. Chet would never had sold a single guitar if all his work looked like that... someone at some point butchered that poor thing... To be honest, the cheapest repair job to get her up and running is the way to go.

To adapt a good quality changer from another builder would require money, time, and some good woodworking skills, and the effort and cost would likely outstrip the value of the guitar by a good margin,, Wilcox guitars are not considered "desirable" to most steel players, but many members do have them and like them fine. I just would not put a lot into it.. Play it after the repair, save your nickels, and when the time is right for you, move on to a better quality guitar... bob

_________________

I'm over the hill and hittin'rocks on the way down!

no gear list for me.. you don't have the time...... |

|

|

|

Pete Burak

From:

Portland, OR USA

|

Posted 13 Feb 2019 10:07 am

Posted 13 Feb 2019 10:07 am |

|

If you are not lowering string 6, you can secure the lowering finger in place without using a spring.

Look at other options.

For example, If the other end of the spring is held in place with a screw, you could screw down an L-shaped piece of metal or wood, to hold the finger in place.

I once tied off a lowering finger with a piece of a wound guitar string, making a loop thru the ball end.

The only reason they use springs is so a string can be raised AND lowered.

I would either file a notch or hand drill a hole near the red mark in Richard Burton's pic, and tie that kangaroo down!  |

|

|

|

Doug Earnest

From:

Branson, MO USA

|

Posted 13 Feb 2019 10:22 am

Posted 13 Feb 2019 10:22 am |

|

Maybe that was one of Chet's really early attempts. He was the first to tell you that some of the work was crude, and he did improve substantially over time.

Remove all the springs and have your welder buddy tig close the spring hook in each finger, leaving a bit of a hole (or small spot where you can easily drill one out) to reattach the springs. If he is a good welder he can likely do it while it's still on the guitar. Or weld on a little patch panel with a hole. It's amazing what some of those tig guys can do! I used to watch them repair turbine blades.

You will probably have a decent playing guitar, certainly plenty good enough to learn to play a lot on. Most of us started with far less. |

|

|

|

Pete Burak

From:

Portland, OR USA

|

Posted 13 Feb 2019 10:55 am

Posted 13 Feb 2019 10:55 am |

|

| What is going on with string 10? Is that also a new spring? It looks like it is out of place in the opposite direction of string-6? |

|

|

|

Bob Carlucci

From:

Candor, New York, USA

|

Posted 13 Feb 2019 10:57 am

Posted 13 Feb 2019 10:57 am |

|

| Doug Earnest wrote: |

Maybe that was one of Chet's really early attempts. He was the first to tell you that some of the work was crude, and he did improve substantially over time.

Remove all the springs and have your welder buddy tig close the spring hook in each finger, leaving a bit of a hole (or small spot where you can easily drill one out) to reattach the springs. If he is a good welder he can likely do it while it's still on the guitar. Or weld on a little patch panel with a hole. It's amazing what some of those tig guys can do! I used to watch them repair turbine blades.

You will probably have a decent playing guitar, certainly plenty good enough to learn to play a lot on. Most of us started with far less. |

While I have never played a Wilcox steel or seen one close up, I have seen plenty of underside pics of them.. None ever looked like this one.. They looked pretty much like lots of other mid range steel guitars..

Lots of guys have and like them just fine..bob

_________________

I'm over the hill and hittin'rocks on the way down!

no gear list for me.. you don't have the time...... |

|

|

|

Tony Prior

From:

Charlotte NC

|

Posted 13 Feb 2019 11:06 am

Posted 13 Feb 2019 11:06 am |

|

lots of great idea's , don't throw it away ! If you lived near me we would have already fixed it, one way or another ! A little ingenuity and creativity goes a long way around here !

_________________

Emmons L-II , Fender Telecasters, B-Benders , Eastman Mandolin ,

Pro Tools 12 on WIN 7 !

jobless- but not homeless- now retired 9 years

CURRENT MUSIC TRACKS AT > https://tprior2241.wixsite.com/website |

|

|

|

Dom Franco

From:

Beaverton, OR, 97007

|

Posted 13 Feb 2019 12:21 pm

Posted 13 Feb 2019 12:21 pm |

|

IMHO a Pedal steel guitar player needs to be somewhat mechanically inclined. If not he/she should take every opportunity to learn to work on, adjust, clean, lube, repair, modify his particular instrument. It's simple machinery and it's going to need some maintenance.

I enjoyed the challenge learning how my 1st pedal steel worked many years ago. I think it helps as you begin to play better and you notice something is "not quite right" so you need to adjust a stop on a pedal or knee lever, tune a raise or lower, tighten a loose nut etc.

_________________

https://www.youtube.com/channel/UCYG9cvwCPKuXpGofziPNieA/feed?activity_view=3 |

|

|

|

Jerry Roller

From:

Van Buren, Arkansas USA

|

Posted 13 Feb 2019 9:11 pm

Posted 13 Feb 2019 9:11 pm |

|

If you are mechanically capable of taking the changer apart I would suggest you trade that finger assembly out with one that does not do anything. Or get someone who can to do it. You would need to lock the damaged one with a screw or rivet so it could not pivot. It would only serve to attach the string to. No spring would be needed on it. Mr Wilcox made his parts by hand as he didn’t have machinery. He just had a love for steel guitars. I doubt if there was much similiarity in parts from one guitar to the other. I doubt if he made $5.00 an hour building guitars.

It would also be possible to rig a spring loaded push rod to push that finger back against the stop to serve the same purpose as that spring. You would not have to take the changer apart. Which string is on the broken finger? Maybe I or someone can tell you how to rig the push rod. Not too much of a job.

Jerry

rollermusic@cox.net

_________________

http://www.littleoprey.org/ |

|

|

|

Brandon Stanek

From:

Minnesota, USA

|

Posted 14 Feb 2019 5:18 am

Posted 14 Feb 2019 5:18 am |

|

Hey everyone! My friend was able to rig something up for me! It may not be super pretty to look at but it’s functional. So glad he was able to figure something out. Thanks again for everyone’s suggestions and help. It’s greatly appreciated!

|

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 14 Feb 2019 7:01 am

Posted 14 Feb 2019 7:01 am |

|

That's fantastic that you are now functional.

Some years ago there were some alarming posts of frustration about Wilcox steels. Then the reports started coming in that he had really gotten better. I got the impression that the earliest ones were rather grim. I hope that this can now be played without concern about future issues. Playing, not fixing, is what you want to be doing.

Congrats.

--btw, is there a serial number stamped on it? |

|

|

|

Brandon Stanek

From:

Minnesota, USA

|

Posted 14 Feb 2019 7:10 am

Posted 14 Feb 2019 7:10 am |

|

| It’s number 207. Signed July of 2013. |

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 14 Feb 2019 7:37 am

Posted 14 Feb 2019 7:37 am |

|

Ok--that leads me to guess that this steel has indeed been hacked.

I don't know how to read that serial number but re: the date, I'm seeing posts showing that Chet Wilcox was building guitars back in 2006 at least. If his building improved over time...that just doesn't make sense as a 2013 build unless someone took crude tools to it later. |

|

|

|

Jerry Roller

From:

Van Buren, Arkansas USA

|

Posted 14 Feb 2019 9:31 am

Posted 14 Feb 2019 9:31 am |

|

It is amazing what people do to a good guitar. My blue mica woodneck D10 had the bottom of all 20 changer lowering fingers hack sawed off! This eliminated the tuning screws that the raise fingers landed on. I had to rebuild the changers and replace the lowering members. The early Wilcox changers were made of thin material.

Jerry

_________________

http://www.littleoprey.org/ |

|

|

|