| Author |

Topic: Lap steel Build . Where do you get your wood? |

Jeff Metz Jr.

From:

York, Pennsylvania, USA

|

Posted 18 Sep 2016 8:14 am

Posted 18 Sep 2016 8:14 am |

|

Im about to take on a small lap steel build. My question is, where do you guys find nice pieces of wood for a build? I don't wanna buy stuff from lowes or home depot , as I don't think that wood would sounds very good. (poet? )

Anywhoo, What are your recommendations for type of wood to use, and where to acquire it? Thanks

_________________

Mullen G2 SD10 , Lil Izzy Buffer, Goodrich 120 volume pedal, Boss DD-7, Peterson Strobo flip, Peavey Nashville 112 |

|

|

|

Dale Foreman

From:

Crowley Louisiana, USA

|

Posted 18 Sep 2016 8:32 am Wood

Posted 18 Sep 2016 8:32 am Wood |

|

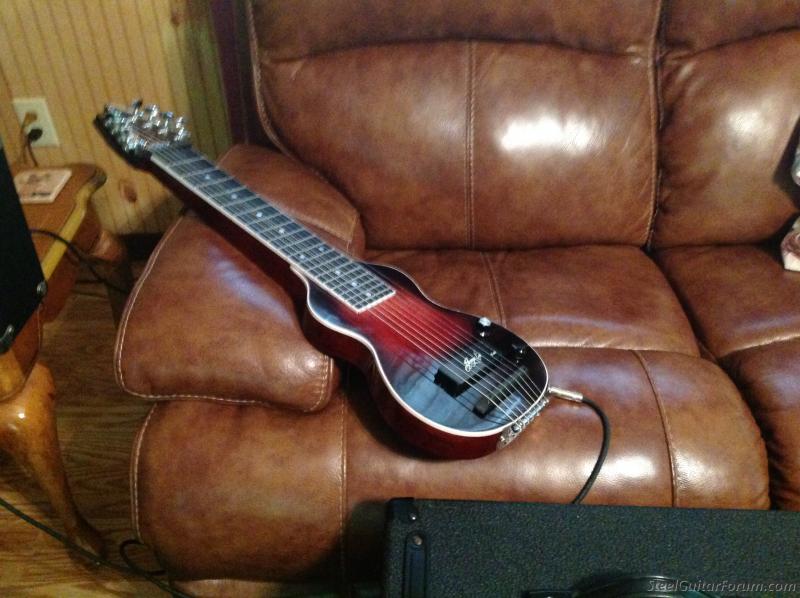

I used swamp ash.

[/url] [/url]

_________________

Rittenberry Prestige(2) |

|

|

|

Jon Light

From:

Saugerties, NY

|

Posted 18 Sep 2016 8:44 am

Posted 18 Sep 2016 8:44 am |

|

| A simple google of luthier wood will help you find it for yourself. |

|

|

|

George Piburn

From:

The Land of Enchantment New Mexico

|

|

|

|

Robert Allen

From:

Tennessee, USA

|

Posted 18 Sep 2016 9:11 am Wood sources

Posted 18 Sep 2016 9:11 am Wood sources |

|

Here are some sources for affordable wood, not listed as luthier grade so you will likely need to cut out the knotty and split parts. The yield is about 80%. Minimum is usually 20 bd ft which will make 2 or 3 lap steels. It helps to tell them you'll be using it for musical instruments. So-called "luthier grade" expensive lumber is sometimes no better than FAS non-luthier grade. Depends where you buy. Doing a Google search doesn't separate the good from the bad. After you buy, you know. I buy a lot of wood locally where I can see what I'm getting. It's really the best way if there is a mill or lumberyard near you.

www.badgerwood.com

www.niagaralumber.com

http://www.ocoochhardwoods.com/ |

|

|

|

Andy Henriksen

From:

Michigan, USA

|

Posted 19 Sep 2016 7:26 am Re: Wood

Posted 19 Sep 2016 7:26 am Re: Wood |

|

| Dale Foreman wrote: |

| I used swamp ash. |

Hey Dale, how thick was that slab? How wide is the body portion? I'm thinking of making a guitar of a similar design (have been for a few years now...just haven't quite gotten started). I seem to either find wood locally that seems wide enough or thick enough, but not both. And I like the idea of it being a single piece, not laminated.

Last edited by Andy Henriksen on 19 Sep 2016 8:02 am; edited 1 time in total |

|

|

|

Mark Eaton

From:

Sonoma County in The Great State Of Northern California

|

Posted 19 Sep 2016 7:43 am

Posted 19 Sep 2016 7:43 am |

|

Earlier posts provided links to lumber/wood suppliers.

Along with all the wine/vineyards and craft beer producers, we are surrounded here in Sonoma County (b0b lives a little over 20 miles north of me) with luthiers. The grapes like the climate, and it is also good for building guitars. So this has given rise over the years to couple full service suppliers of tonewoods and everything else you need. One stop shopping. I don't know off the top of my head if they have the slabs necessary to build a lap steel, but the guys at both places are very knowledgeable and it's worth checking out.

Luthier's Mercantile is in my town of Windsor:

http://www.lmii.com/

About five miles north in Healdsburg is Allied Lutherie:

http://alliedlutherie.com/

_________________

Mark |

|

|

|

Jonathan Scherer

From:

Stehekin, Washington

|

Posted 19 Sep 2016 11:43 pm

Posted 19 Sep 2016 11:43 pm |

|

You might be surprised by the number of small saw mills and hardwood lumber suppliers in your area. In fact there could be some great lap wood salvaged from a tree in your town square, air dried a few years and just waiting to sing steel!

_________________

1948 National Dynamic, 1953 Oahu Tonemaster,cheap Aiersi Weissenborn, Hambro custom square neck reso, Carvin X-60A, Fender Acoustasonic 30

and 10, Roland Cube Street |

|

|

|

Tom Pettingill

From:

California, USA (deceased)

|

Posted 20 Sep 2016 8:12 am

Posted 20 Sep 2016 8:12 am |

|

| Quote: |

| What are your recommendations for type of wood to use, and where to acquire it? |

Its hard to make a particular wood recommendation without knowing your end goal for tone and how you want it to sound. Also a major part of the equation is the pickup you plan to use or need to use to get there.

Its my experience that while all the parts of an instrument and its construction contribute to the end result, its the pickup(s) and electronics that contribute the lions share to the mix. The type / species of wood certainly plays a part, but I think of it as more of a complimentary spice in the recipe. Different woods can accentuate or alternatively attenuate certain frequencies. It can also play a part in note attack, bloom, and decay.

All that said, good wood is where you find it. Look for a local hardwood dealer that supplies to the custom cabinet shops and the like. They usually carry a good selection of the main domestic species like maple, alder, ash, poplar, walnut, etc. They also should have a fair offering of some of the more common imports like mahogany, sapele, and maybe some other more exotics.

Again, without knowing all the particulars or your level of woodworking experience and desired tone, its hard to say whats right for you. If I had to make a blanket recommendation, you might try some poplar for your first project. Its cheap, easy to work with, and very neutral in its sonic contribution.

_________________

Some misc pics of my hand crafted steels

Follow me on Facebook here |

|

|

|

David Mason

From:

Cambridge, MD, USA

|

Posted 20 Sep 2016 2:26 pm

Posted 20 Sep 2016 2:26 pm |

|

Drying and curing is what separates "luthier" wood from "merely cute" wood. I have read wise internet "advice" on how to figure out water content for wood by size (volume) and weight(?), just say "no." It does come down to trusting your supplier, and the thicker and one-piecier* the wood gets, the more important this gets! I've spent a bit of time on this at builder sites, that world is rife with people... emotionally-connected to certain boards?  The ol' porch swing, grandpa's canoe etc. The luthier wood-sellers will cure it for you, but it takes two years. If you've got a TREE, they will accept payment in wood, some of 'em. The ol' porch swing, grandpa's canoe etc. The luthier wood-sellers will cure it for you, but it takes two years. If you've got a TREE, they will accept payment in wood, some of 'em.

*(is now) |

|

|

|

Robert Allen

From:

Tennessee, USA

|

|

|

|

Per Berner

From:

Skovde, Sweden

|

Posted 23 Sep 2016 5:52 am

Posted 23 Sep 2016 5:52 am |

|

| Well, many vendors offer wood for guitars, but very few offer pieces of a suitable size for a lap steel. Too short, too thin or too narrow is the norm from the usual lutherie suppliers. So recommendations and tips are welcome – we don't want to be stuck with boatbuilders' mahogany or furniture makers' oak... |

|

|

|

Jouni Karvonen

From:

Helsinki, Finland

|

Posted 23 Sep 2016 7:17 am

Posted 23 Sep 2016 7:17 am |

|

Here's a rude sample made from 2" X 4" mahogany plank, that they called 'warehouse dry'. It was made in '07; woodwork by my friend in the picture. My design and mutual assembly. It plays and stays in tune well. I came to this after seeing SuperSlide 12 and tried to place an order, no replies. So lowering standards i'm happy with the thing.

|

|

|

|

Gary Meixner

From:

New York, USA

|

Posted 23 Sep 2016 7:59 am

Posted 23 Sep 2016 7:59 am |

|

Jeff,

Unless you have specific requirement as far as tone or appearance almost any hardwood will make a nice sounding guitar. I would not worry about finding a piece of wood that was intentionally selected, cut and dried as a tonewood.

George P. has made several good suggestions as far species and lumber dealers. The state of Pennsylvania is home to some of finest hardwood forests anywhere in the world. Chances are there is a local supplier who can help you. Any hardwood dealer who sells to general woodworkers, furniture makers, cabinet maker, etc., will most likely have something you can use.

I was in the hardwood lumber business for many years and could go into much detail about how hardwood trees are grown, selected, sawed, how lumber is graded, dried, milled, marketed, etc.

American Ash and Tulip Poplar have been used extensively for solid body guitars. They are both inexpensive. Dry easily with few defects. And work easily with common hand tools. A piece of 8/4 stock (1-3/4" finished thickness) x 8" wide ad 36" long would be more than enough for a lap steel guitar. This equals 4 board feet and should cost you under $25.00

If you have any other questions I am happy to help. Best of luck.

Gary Meixner |

|

|

|

Alan Berdoulay

|

Posted 27 Sep 2016 4:46 am

Posted 27 Sep 2016 4:46 am |

|

| Jeff........check out Hearne Hardwoods....... http://www.hearnehardwoods.com/. Friendly people. Into guitars. They're a sawmill with a department dedicated to guitar wood. They carry many species from around the world (including piles of walnut...but check out the Koa or Ebony logs). All levels of figure. Located in Oxford, Pa. About an hour east of you. In fact, they're having their open house this Friday and Saturday. Live music, food, vendors and demos....including the 67" vertical bandsaw. |

|

|

|

George Piburn

From:

The Land of Enchantment New Mexico

|

Posted 27 Sep 2016 6:51 am Hard Wood

Posted 27 Sep 2016 6:51 am Hard Wood |

|

I totally agree with Alan, Hearne is where I would go for certain.

Hopefully you will extend this thread and talk about your ideas for your project.

We all are ready to chime in with advice and more goodies for you.

Knowing your wood work skills and tool level will help us too.

I can say -- if you are just wanting a single small plank --

your local WoodCraft store typically stock some exotic single boards large and thick enough to make a steel or 2.

_________________

GeorgeBoards S8 Non Pedal Steel Guitar Instruments

Maker of One of a Kind Works of Art that play music too.

Instructional DVDs

YouTube Channel |

|

|

|

Alan Berdoulay

|

Posted 27 Sep 2016 8:03 am

Posted 27 Sep 2016 8:03 am |

|

I've read on this forum......comments like....."you can't get birds eye maple like that any more". I usually refrain from promoting Hearnes because I work there from time to time.

Hearne Hardwoods is a sawmill. Rick travels the world buying the best of the best in hardwoods.....usually in the log. They turn it into whatever....conference tables to fretboards...and everything in between.

Figured maple....they've got piles of it. Rosewood, Mahogany, Ebony, Koa, Cocobola, Blackwood, Ziricote.....pretty much anything that's extraordinary (and not endangered).....they have it. Check em out. |

|

|

|

Jeff Metz Jr.

From:

York, Pennsylvania, USA

|

Posted 20 Nov 2016 6:45 pm

Posted 20 Nov 2016 6:45 pm |

|

So I found a nice rough sawn plank of black walnut. Been drying for 5+ years. 2 1/2" thick , 13" wide and 6' long. Paid $30 for it and will be shaping tomorrow.

Will be topping the guitar with maple and Inlaying the sides with curly maple banding and pearl binding. I will document the build.

_________________

Mullen G2 SD10 , Lil Izzy Buffer, Goodrich 120 volume pedal, Boss DD-7, Peterson Strobo flip, Peavey Nashville 112 |

|

|

|

Petter Tornqvist

From:

Sweden

|

Posted 21 Nov 2016 4:16 am

Posted 21 Nov 2016 4:16 am |

|

If you are able to find it, I can warmly recommend Wenge. Incredible sustain. A pain in the ass to work with.. but worth it.

Here is a guitar i recently finished in Wenge.

_________________

Fender 400! |

|

|

|

Alan Berdoulay

|

|

|

|