| Author |

Topic: Lighten lever action with minimal travel increase? |

Jim Williams

From:

Meridian, Mississippi, USA - Home of Peavey!

|

Posted 9 Apr 2014 7:18 am

Posted 9 Apr 2014 7:18 am |

|

I have a Carter Starter...no bashing please, I know it is a beginner guitar. I'm actually very pleased with it except that the LKR (lower E's) lever is very stiff and fairly long travel.

Is there any way to lessen the tension without drastically adding more travel? The return springs on this are of course not adjustable...anyone ever try a slightly lighter spring, or even some type of helper spring? I have to believe that the guitar would have been designed with as close to the optimum tension on that spring as possible, considering it is not adjustable.

I know there are basic laws of motion and physics here that can't be fully overcome, but I'm short anyway and that lever is very awkward for me. It is particularly awkward when it has to be used in combination with a pedal.

Also another question that comes to mind...the springs on all the levers seem the same, that along with the fact that this is a lower not a raise makes me wonder why it would be so much stiffer?

_________________

GFI SM10 3/4, 1937 Gibson EH-150, 2 - Rondo SX Lap Steels and a Guyatone 6 String C6. Peavey 400 and a Roland 40 Amps. Behringer Reverb Pedal.

Last edited by Jim Williams on 9 Apr 2014 10:56 am; edited 1 time in total |

|

|

|

Tom Gorr

From:

Three Hills, Alberta

|

Posted 9 Apr 2014 7:24 am

Posted 9 Apr 2014 7:24 am |

|

Never seen a 'starter', but if it has a normal changer, it will have 'lower' return springs, and its possible they can be adjusted or replaced with a lighter spring of same length.

Look under your guitar at the changer end and you will see a row off springs fastened to the changer, and then reach up and move the lever, and you will see what I'm talking about.

Some guitars have way too stiff of return springs. |

|

|

|

Mike Wheeler

From:

Delaware, Ohio, USA

|

Posted 9 Apr 2014 7:29 am

Posted 9 Apr 2014 7:29 am |

|

Jim, your best option is to have an experienced player look at it. Aside from that, if you shorten the lever travel, it will get stiffer...no way around that. But there might be a problem in the mechanism...maybe it needs some lube.

The E lower lever is lessening the tension of strings 4 and 8, so the return spring is where you are getting the resistance. You might need to loosen up the spring a bit, but if you aren't experienced in doing it you could overdo it. Again, I advise you have an experienced player, or a steel shop, look at it. They can correctly sort it out for you.

_________________

Best regards,

Mike |

|

|

|

Jim Williams

From:

Meridian, Mississippi, USA - Home of Peavey!

|

Posted 9 Apr 2014 7:58 am

Posted 9 Apr 2014 7:58 am |

|

Tom, yes I have spent much more time underneath this thing than I would like, so I am familiar with the return springs. That was my first thought to see if I can find a spring locally just a bit lighter. If it doesn't have quite enough pull to return the string to normal pitch, I would then take a turn off at a time until hopefully I find a happy spot that gives reduced resistance but still returns to the correct note. I don't plan to alter the original spring, so anything I do could be reversed if it doesn't work out. I have the rodding chart for the guitar and they recommend using the hole on the bellcrank that produces the current shorter but stiff movement. I've tried different bellcrank holes, but then the travel becomes a problem with my short legs.

Mike, unfortunately I really don't have access to anyone here to work on the guitar, but I would certainly be receptive to that approach if I did.

_________________

GFI SM10 3/4, 1937 Gibson EH-150, 2 - Rondo SX Lap Steels and a Guyatone 6 String C6. Peavey 400 and a Roland 40 Amps. Behringer Reverb Pedal. |

|

|

|

Lane Gray

From:

Topeka, KS

|

Posted 9 Apr 2014 12:06 pm

Posted 9 Apr 2014 12:06 pm |

|

Jim, have you ever thought of firing off an email to Mike Brown? I bet that Meridian DOES have some steelers, and Mike might know them. Also ask the folks at the music store(s) in town. The guys behind the counter have probably sold pix and bars...

NEVER assume you're alone.

_________________

2 pedal steels, a lapStrat, and an 8-string Dobro (and 3 ukes)

More amps than guitars, and not many effects |

|

|

|

Jim Williams

From:

Meridian, Mississippi, USA - Home of Peavey!

|

Posted 9 Apr 2014 12:27 pm

Posted 9 Apr 2014 12:27 pm |

|

Thanks for the advice Lane. I may stop by the local music store on the way home today and ask about steelers around here. I picked up a spring today that I might try lowering the tension a bit with, but to be honest after taking the original one off, I'm not very optimistic about this. It is a very stiff spring with a very short travel. It is probably going to be a delicate balance between enough pull and too little, and I may not have the right type spring to fall into that category.

_________________

GFI SM10 3/4, 1937 Gibson EH-150, 2 - Rondo SX Lap Steels and a Guyatone 6 String C6. Peavey 400 and a Roland 40 Amps. Behringer Reverb Pedal. |

|

|

|

Mike Wheeler

From:

Delaware, Ohio, USA

|

Posted 9 Apr 2014 2:01 pm

Posted 9 Apr 2014 2:01 pm |

|

Jim Palenscar probably has a new spring so you'd have one to experiment with. Also, he could give you great advice over the phone to help you figure things out.

_________________

Best regards,

Mike |

|

|

|

Jim Williams

From:

Meridian, Mississippi, USA - Home of Peavey!

|

Posted 9 Apr 2014 10:29 pm

Posted 9 Apr 2014 10:29 pm |

|

I spent a while underneath the Starter tonight and tried a few things. I don't really think it is going to get a whole lot better than I have it right now. I changed the hole in the bell cranks one space on both e strings...anything more just makes for too much travel. I think one thing contributing to the stiffness is that the two E rods and the stop rod take a pretty hard bend over the RKR cross shaft shortly before connecting to the changer. This creates friction, and some objectionable noise as well. I lubed everything with Teflon lube. I'm really not using that lever much at this point..I might try temporarily removing that cross shaft just to see how much effect it is having. Unfortunatly the changer only has one connection for lowers, so rerouting the rod isn't really feasible. I've also thought about putting a Teflon sleeve for the rod to crossover the shaft instead of metal on metal. Anyway about the only other thing I might tackle is putting a couple of "real" stops under there instead of the current mixture of excuses for stops. To be honest this is a temporary guitar anyway. I'm seriously thinking of putting in an order with either Doug at Stage One or Bob Simmons for a better guitar. I'll learn as much as I can, mod it a bit and then put it up for sale in a few months when my new one is nearing completion.

_________________

GFI SM10 3/4, 1937 Gibson EH-150, 2 - Rondo SX Lap Steels and a Guyatone 6 String C6. Peavey 400 and a Roland 40 Amps. Behringer Reverb Pedal. |

|

|

|

Tom Sosbe

From:

Rushville,In

|

Posted 10 Apr 2014 6:53 am

Posted 10 Apr 2014 6:53 am |

|

I have worked on 2 starters . I don't remember any bent rods. something is wrong under there.

tom |

|

|

|

Peter den Hartogh

From:

Cape Town, South Africa

|

Posted 10 Apr 2014 7:25 am

Posted 10 Apr 2014 7:25 am |

|

Does the Carter Starter have round shafts?

If so, the angle of the bell crank may play a role.

Apparently there is an optimum angle for it to work properly.

I believe the start of the bell crank travel should be just a couple of degrees

before the bell crank reaches the 90 degree position and then it must swing a couple of degrees more.

I might be wrong so please check it with the experts.

Another consideration:

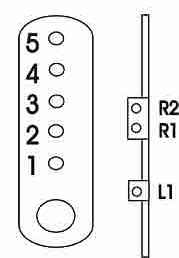

A "Numbering Convention" for rodding your Carter-Starter is shown below.

This is done with the underside of the steel guitar facing up.

(The same position the guitar uses in the case.)

This could be very confusing as the bell crank holes are counted from the inside of the wood body, BUT the finger holes are counted from the floor with the guitar standing upright and NOT from the wood body inside!

http://www.steelguitar.com/carter/csroddingchart.html |

|

|

|

Lane Gray

From:

Topeka, KS

|

Posted 10 Apr 2014 8:11 am

Posted 10 Apr 2014 8:11 am |

|

You could try experimenting with helper springs pulling from bellcrank to deck, or from lever to deck.

_________________

2 pedal steels, a lapStrat, and an 8-string Dobro (and 3 ukes)

More amps than guitars, and not many effects |

|

|

|

Jim Williams

From:

Meridian, Mississippi, USA - Home of Peavey!

|

Posted 10 Apr 2014 8:26 am

Posted 10 Apr 2014 8:26 am |

|

Thanks for the suggestions guys. Yes Peter, it does have round shafts, but the bellcranks are welded to the shafts, so I really don't know how much you could adjust the angles. The rods I'm referring to have to either go over or under (with the guitar rightside up) the last shaft which is mounted near the bottom of the guitar and lowers string 2 only. I tried rerouting to the other side of the shaft but that didn't really help a whole lot, they just rubbed on the opposite side  . .

Lane, I had thought about that and might give it a try with a few small springs I have on hand.

I also have a lead on a BMI S10 within easy driving distance. I am probably going down to look at it and play it Sunday. It appears to be almost mint condition, 3/3 and according to the owner has no problems. I figure it is definitely worth a tank of gas to go look at it.

If I like it I will most likely buy it and sell the Carter and recover a good chunk of the money I spend on the BMI. I got the Carter at a bargain so I will probably actually make a couple of hundred on the sale hopefully.

I liked my BMI that I had previously very well, but the wear on it and cost of rebuilding / adding to it just didn't make economic sense.

_________________

GFI SM10 3/4, 1937 Gibson EH-150, 2 - Rondo SX Lap Steels and a Guyatone 6 String C6. Peavey 400 and a Roland 40 Amps. Behringer Reverb Pedal. |

|

|

|

Will Cowell

From:

Cambridgeshire, UK

|

Posted 10 Apr 2014 1:29 pm

Posted 10 Apr 2014 1:29 pm |

|

I started with one of these little Carters, and I don't remember the problem you are describing. I'd put a few bucks on there being something in the changer that is out of kilter, or needing lubrication. I'm hoping you can find a steel guitar tech there or close by, because that behaviour isn't typical of the Carter Starter. Good luck!

_________________

Williams 700 series keyless U12,

Sierra keyless U14, Eezzee-Slide & BJS bars

Moth-eaten old Marshall 150 combo

Roland Cube 80XL, Peterson Strobo+HD,

EarthQuaker Despatch Master for reverb / delay |

|

|

|

Jim Williams

From:

Meridian, Mississippi, USA - Home of Peavey!

|

Posted 11 Apr 2014 9:42 am

Posted 11 Apr 2014 9:42 am |

|

Its a little strange and I can't really find much info on it online, but there appears to have been at least two "versions" of the Starter. I say this because I have seen photos of the under carriage of them online that are a lot different than mine is as to the positioning of the cross shafts and consequently the path of the rods. Looking at the body from the bottom, a lot of the photos I see have the shafts mounted closely underneath the "top" of the guitar. Some of my cross shafts however, including the RKR lever one is mounted on a bracket that places it near the "bottom" of the guitar. This is what causes the E rods to have to make a bend around the cross shaft and create friction.

Another thing I notice is that some of the photos I see have a reversing bracket on one or more of the cross shaft assemblies...mine has none of these. All levers are bolted directly to the cross shaft.

Mine is one of the later ones made I believe. I thought when I bought it that this was a good thing, now I'm beginning to wonder if the design was stripped down as some point to keep costs down.

_________________

GFI SM10 3/4, 1937 Gibson EH-150, 2 - Rondo SX Lap Steels and a Guyatone 6 String C6. Peavey 400 and a Roland 40 Amps. Behringer Reverb Pedal. |

|

|

|

Paul Redmond

From:

Illinois, USA

|

Posted 14 Apr 2014 7:47 pm

Posted 14 Apr 2014 7:47 pm |

|

I've worked on a few of these in the past, and the culprit seems to be friction. So I milled a small pocket in one of the two "arms" in the contact areas, then press-fit a 1/8" thick nylon insert in the pocket. One drop of oil and problem solved. But you need access to a milling machine and some 1/8" Zytel 101 nylon sheet.

PRR |

|

|

|