| Author |

Topic: 3D printing music instruments |

Jan Viljoen

From:

Pretoria, South Africa

|

Posted 30 Jun 2013 12:43 am

Posted 30 Jun 2013 12:43 am |

|

This may be the science of the future, 3D printing musical instruments, using all kinds of material.

Who will do the first pedal steel?

http://createdigitalmusic.com/2012/10/six-3d-printed-musical-instruments-and-what-3d-printing-could-do-for-musicians/

This flute was printed in 15 hours.

Copy of a Stradivarius violin.

Playing another 3D printed violin in London.

http://www.youtube.com/watch?v=bJA6J5girlo

Let the games begin!

_________________

Sierra S10, Stage One, Gibson BR4, Framus, Guya 6&8, Hofner lap, Custom mandolins, Keilwerth sax.

Roland Cube 80XL, Peavey112-Valve King and Special, Marshall 100VS. |

|

|

|

Ken Byng

From:

Southampton, England

|

Posted 30 Jun 2013 2:39 am

Posted 30 Jun 2013 2:39 am |

|

Jan

While this subject is fascinating and has been discussed on this forum before, the creation and manufacturing of virtually all mechanical stringed musical instruments is very highly dependent in much of the process upon human involvement and intervention.

3D modelling will not encompass the skilled eye of a luthier who hand selects the timber for its resonance and physical beauty / attractiveness. A pedal steel's tone is the result of the sum of its parts and its design. Likewise a Stradivarius can be physically emulated as far as its dimensions are concerned, but impossible to replicate tonally from a 3D printer.

It will be many many years before technology evolves enough to be able to quickly reproduce the most important aspect of any instrument - its tone and timbre.

_________________

Show Pro D10 - amber (8+6), MSA D10 Legend XL Signature - redburst (9+6), Sho-Bud Pro 111 Custom (8+6), Emmons black Push-Pull D10 (8+5), Zum D10 (8x8), Hudson pedal resonator. Telonics TCA-500, Webb 614-E,

Last edited by Ken Byng on 1 Jul 2013 1:21 am; edited 2 times in total |

|

|

|

Jan Viljoen

From:

Pretoria, South Africa

|

Posted 30 Jun 2013 2:59 am

Posted 30 Jun 2013 2:59 am |

|

Thanks Ken,

I agree with you in principle, but I think in time adjustments to future software to vary acoustic properties and thicknesses, will come close to the real mccoy.

In a 5 man band with full volume I can't distinguish between a USA, Mexican, Japanese or Korean telecaster either.

I suppose in future printing will also be done with maple fibres (with synthetic flames), gold dust and ivory filings.

_________________

Sierra S10, Stage One, Gibson BR4, Framus, Guya 6&8, Hofner lap, Custom mandolins, Keilwerth sax.

Roland Cube 80XL, Peavey112-Valve King and Special, Marshall 100VS. |

|

|

|

Norman Boling

From:

Paragould Arkansas, Philadelphia TN USA

|

Posted 30 Jun 2013 3:19 am Printing

Posted 30 Jun 2013 3:19 am Printing |

|

| When Buddy Emmons can be printed I'll be concerned |

|

|

|

Scott Duckworth

From:

Etowah, TN Western Foothills of the Smokies

|

Posted 30 Jun 2013 3:31 am

Posted 30 Jun 2013 3:31 am |

|

I would be good if parts for older pedal steels could be reproduced...

_________________

Amateur Radio Operator NA4IT (Extra)

http://www.qsl.net/na4it

I may, in fact, be nuts. However, I am screwed onto the right bolt... Jesus! |

|

|

|

John Roche

From:

England

|

Posted 30 Jun 2013 3:39 am

Posted 30 Jun 2013 3:39 am |

|

| Cad drop would be an issue. lol |

|

|

|

Jan Viljoen

From:

Pretoria, South Africa

|

Posted 30 Jun 2013 4:29 am

Posted 30 Jun 2013 4:29 am |

|

I found this website regarding printable materials for instruments.

Looks like were are only starting now.

http://3dprintedinstruments.wikidot.com/materials

_________________

Sierra S10, Stage One, Gibson BR4, Framus, Guya 6&8, Hofner lap, Custom mandolins, Keilwerth sax.

Roland Cube 80XL, Peavey112-Valve King and Special, Marshall 100VS. |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 30 Jun 2013 7:34 am

Posted 30 Jun 2013 7:34 am |

|

It's simply not necessary or practical for a pedal steel to be made this way. Acoustic instruments are a different story - they have sound chambers (and they don't have hundreds of little metal parts). Solid bodied electric instruments can be made cheaper and faster without all this technology. So, until it's somehow magically cheaper to do it with a printer, it will not happen.  |

|

|

|

Daniel McKee

From:

Corinth Mississippi

|

Posted 30 Jun 2013 10:15 am

Posted 30 Jun 2013 10:15 am |

|

| I still think its amazing that they can make instruments that actually work with a 3D printer.It may not be practical yet but its still pretty awesome. |

|

|

|

Dan Beller-McKenna

From:

Durham, New Hampshire, USA

|

Posted 30 Jun 2013 11:59 am

Posted 30 Jun 2013 11:59 am |

|

| I think Scott is on to something. Even if it were a three-step process to produce an all-pull finger with a head, and a two part scissor, and even if they all had to be separately riveted, couldn't this have the potential (down the line a little ways) to be an easier way to replicate out of production parts (said the new owner of a pot-metal filled Super Pro, .... hopefully). |

|

|

|

Donny Hinson

From:

Glen Burnie, Md. U.S.A.

|

Posted 1 Jul 2013 9:09 am

Posted 1 Jul 2013 9:09 am |

|

| Dan Beller-McKenna wrote: |

| Even if it were a three-step process to produce an all-pull finger with a head, and a two part scissor, and even if they all had to be separately riveted, couldn't this have the potential (down the line a little ways) to be an easier way to replicate out of production parts (said the new owner of a pot-metal filled Super Pro, .... hopefully). |

Would it be worth it to you to spend over a thousand dollars on a printer and materials just to make a few hundred dollars worth of parts? I'm not altogether sure that (printed) plastic or metalized parts would even be any improvement over pot metal parts. I do feel, though, that an easier way out of your dilemma would be to swap your guitar for one that wasn't filled with pot metal parts!  |

|

|

|

Dan Beller-McKenna

From:

Durham, New Hampshire, USA

|

Posted 1 Jul 2013 12:11 pm

Posted 1 Jul 2013 12:11 pm |

|

Nah,

I am not worried about the short term health of the metal in the guitar I just acquired; not many miles on it. By the time it get's worn down, here's hoping one of our trusty parts makers will have started cranking out aluminum replacement parts.

I was not thinking about each owner buying his or her own printer; we're decades off from these becoming "personal" devices. Good point about the plastic not being any better than pot metal, but who knows what materials they will be using in these down the road and what their acoustic/mechanical properties will be. |

|

|

|

Mark van Allen

From:

Watkinsville, Ga. USA

|

Posted 1 Jul 2013 12:30 pm

Posted 1 Jul 2013 12:30 pm |

|

While looking at a printed plastic flute, bear in mind they're moving toward using "meat ink" to print pork chops... and "stem cell ink" to print new implantable pancreases... not hard to see that technology like this will soon surpass anything we can currently imagine. I foresee some really cool stuff, and some really interesting moral debates.

_________________

Stop by the Steel Store at: www.markvanallen.com

www.musicfarmstudio.com |

|

|

|

Earnest Bovine

From:

Los Angeles CA USA

|

Posted 1 Jul 2013 2:09 pm

Posted 1 Jul 2013 2:09 pm |

|

| Where do I order the new pancreas? |

|

|

|

Mark van Allen

From:

Watkinsville, Ga. USA

|

|

|

|

Clete Ritta

From:

San Antonio, Texas

|

Posted 1 Jul 2013 7:01 pm

Posted 1 Jul 2013 7:01 pm |

|

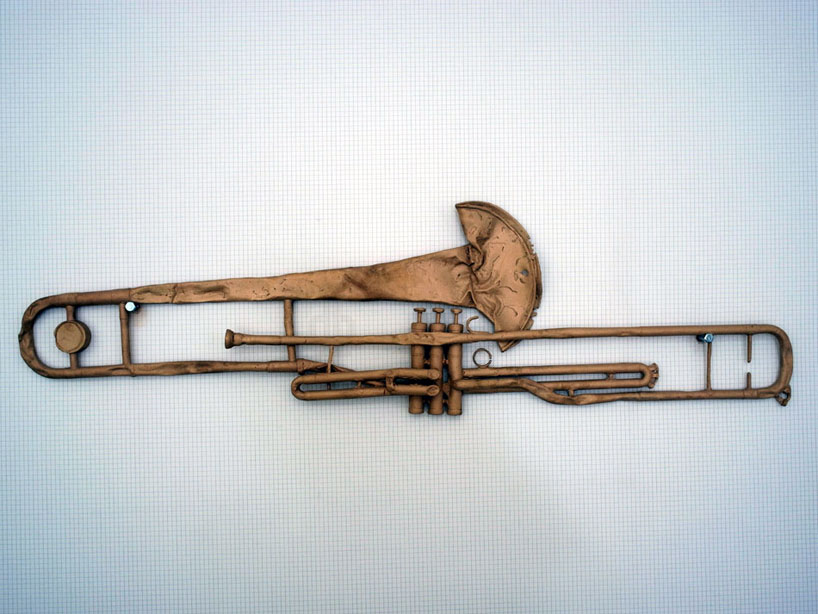

While this trombone is not "printed", plastic has certainly come of age for making some acoustic instruments with fairly decent sound quality. I picked up one of these Jiggs P-Bones for around $100, and its perfectly acceptable (and fun) for me as a beginner's starter instrument.

It may lack a little of the harmonic timbre of brass to some degree, but it is also quite a bit lighter in weight compared to its predecessor. More than a few marching band players are now using them in practice.

My only worry is leaving it outside too long in these heatwaves.  |

|

|

|

Jan Viljoen

From:

Pretoria, South Africa

|

Posted 1 Jul 2013 8:44 pm

Posted 1 Jul 2013 8:44 pm |

|

This thread is getting nice comments and it is getting a life of its own.

Regarding printing body parts, I found this article:

http://www.3ders.org/articles/20130503-australian-researchers-develop-body-parts-using-3d-printing.html

Regarding printing pedal steels I also think that not everybody would have an expensive printer, but I think there will be technical geeks that will print integrated bodies and fret boards.

The materials used will be sorted out eventually.

Printed 6 string electric guitars are already available.

http://www.gizmag.com/awesome-3d-guitar/27387/

By the way, how did the fibre glass psg's sound?

Rods, pickups, legs, and tuners are already available, so that would not be a problem.

_________________

Sierra S10, Stage One, Gibson BR4, Framus, Guya 6&8, Hofner lap, Custom mandolins, Keilwerth sax.

Roland Cube 80XL, Peavey112-Valve King and Special, Marshall 100VS. |

|

|

|

Glenn Uhler

From:

Trenton, New Jersey, USA

|

Posted 2 Sep 2013 10:03 am Replacement parts printing!

Posted 2 Sep 2013 10:03 am Replacement parts printing! |

|

Thanks, Jan, for starting this topic. While visiting my brother-in-law yesterday, he showed me some plastic toys he had printed on his personal 3D printer. They were nice colorful 3D toys made from ABS plastic. What I saw convinced me that replacement and custom plastic parts for vintage instruments can easily be made with one of these printers. Think replacement Rickenbacker plates in either white or black ABS plastic for pennies! All you need to do is program the shape into the printing program. Same with pickup covers and pickguards. Check it out at "Reprap" on the web for one example.

_________________

1974 Marlen S-12 1968 Tele 1969 Martin D-35H |

|

|

|

Jan Viljoen

From:

Pretoria, South Africa

|

Posted 2 Sep 2013 10:21 am 3D Printing

Posted 2 Sep 2013 10:21 am 3D Printing |

|

Thanks Glenn, nice of you to discover this old thread.

Tell us about your 3D plans.

Let the games begin.

_________________

Sierra S10, Stage One, Gibson BR4, Framus, Guya 6&8, Hofner lap, Custom mandolins, Keilwerth sax.

Roland Cube 80XL, Peavey112-Valve King and Special, Marshall 100VS. |

|

|

|

Glenn Uhler

From:

Trenton, New Jersey, USA

|

Posted 2 Sep 2013 11:00 am 3D programming?

Posted 2 Sep 2013 11:00 am 3D programming? |

|

I'm not a programmer, Jan, but I imagine someone familiar with Solidworks could easily write a program for the shapes necessary to make replacement parts. The beauty here is the ability to make only one part without the need for expensive plastic injection molds and the heavy machinery needed to use them. The greatest expense is the initial programming time, but after that each part is made for pennies, just like with injection molding. They are also working at having the 3D printers duplicate themselves.

_________________

1974 Marlen S-12 1968 Tele 1969 Martin D-35H |

|

|

|

Jan Viljoen

From:

Pretoria, South Africa

|

Posted 2 Sep 2013 11:31 am

Posted 2 Sep 2013 11:31 am |

|

Yup, I am sure this science will go from strength to strength, and cheaper eventually.

Go boys, play he game!

_________________

Sierra S10, Stage One, Gibson BR4, Framus, Guya 6&8, Hofner lap, Custom mandolins, Keilwerth sax.

Roland Cube 80XL, Peavey112-Valve King and Special, Marshall 100VS. |

|

|

|

Kevin Hatton

From:

Buffalo, N.Y.

|

Posted 2 Sep 2013 4:34 pm

Posted 2 Sep 2013 4:34 pm |

|

| Except they will NEVER have the sound qualities of of a hand built wood instrument. DOA as far as serious musicians are concerned. |

|

|

|

Glenn Uhler

From:

Trenton, New Jersey, USA

|

Posted 2 Sep 2013 7:14 pm Hand-built wood instrument?

Posted 2 Sep 2013 7:14 pm Hand-built wood instrument? |

|

Totally correct, Kevin, but what about a custom pickup cover for that wood-bodied PSG? Or closer to home, custom case corners with the owners initials in them?

Donny posts earlier and I paraphrase: "Why would you buy a $2000 machine to make a few hundred dollars worth of parts?" That's just this week Donny, what about next week. Would you buy a $2000 car and only expect to drive it once?

_________________

1974 Marlen S-12 1968 Tele 1969 Martin D-35H |

|

|

|

Jan Viljoen

From:

Pretoria, South Africa

|

Posted 2 Sep 2013 8:26 pm 3D Materials

Posted 2 Sep 2013 8:26 pm 3D Materials |

|

Never underestimate scientists or innovative people.

Remember the Wright brothers, Bell, Edison, Tesla?

Even Shot Jackson, Buddy Emmons and the early pioneers?

Wood is already in use and I am sure experimenting will bring out the desired tone, colour and looks.

I said before, that wood fibres, ivory filings, gold dust and now even tungsten will be used.

Check out the internet.

http://www.extremetech.com/extreme/156305-company-develops-new-fiber-reinforced-wood-concrete-ink-for-3d-printing

http://www.3ders.org/articles/20130204-wood-filament-laywoo-d3-suppliers-and-price-compare.html

Thanks guys, use your imagination.

_________________

Sierra S10, Stage One, Gibson BR4, Framus, Guya 6&8, Hofner lap, Custom mandolins, Keilwerth sax.

Roland Cube 80XL, Peavey112-Valve King and Special, Marshall 100VS. |

|

|

|

Ron Randall

From:

Dallas, Texas, USA

|

Posted 3 Sep 2013 5:29 pm

Posted 3 Sep 2013 5:29 pm |

|

Keep an open mind.

If one can imagine a shape, it can be printed.

Back in the day, designing guided missile parts, we would do a "rapid prototype" of complex parts. To visually look at a part sparked lots of imagination. A rapid prototype could be done in a day. To cast it, mold it, or machine it would take weeks or months.

I think it would be useful for making parts in low volume.

Imagine a time when a guitar is ordered, the parts would be made as needed, instead of keeping an inventory. |

|

|

|