| Author |

Topic: Emmons SM Pillow Blocks |

Jerry Overstreet

From:

Louisville Ky

|

Posted 2 Oct 2011 3:26 pm

Posted 2 Oct 2011 3:26 pm |

|

| What's the best way to remove the pillow blocks from an Emmons student changer? The axle doesn't go all the way through. |

|

|

|

Jim Palenscar

From:

Oceanside, Calif, USA

|

Posted 2 Oct 2011 6:57 pm

Posted 2 Oct 2011 6:57 pm |

|

| The changer must be removed from the cabinet and the pillow blocks heated up. |

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 2 Oct 2011 7:19 pm

Posted 2 Oct 2011 7:19 pm |

|

| Thanks Jim. Yeah, the changer is out and on the bench, but I may elect not to disassemble it if it's a tricky operation. |

|

|

|

Tony Glassman

From:

The Great Northwest

|

Posted 2 Oct 2011 7:58 pm

Posted 2 Oct 2011 7:58 pm |

|

Jerry, it's actually pretty easy.

Place one of the pillow blocks in a soft-jaw vice (soft jaws = rubber-coated magnetic inserts that are made to slip onto any vice....mine cost $10/pair), and twist the other block back and forth. It will eventually pop off.

Like Jim said, heating the free pillow block with a hair dryer can help too.

Reassembly is easier yet......Just tap the pillow block back on the axle w/ a rubber mallet and twist it until it's level w/ the other one. |

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 2 Oct 2011 8:19 pm

Posted 2 Oct 2011 8:19 pm |

|

| Thanks fellows. May give it a shot. |

|

|

|

Tony Glassman

From:

The Great Northwest

|

Posted 2 Oct 2011 9:10 pm

Posted 2 Oct 2011 9:10 pm |

|

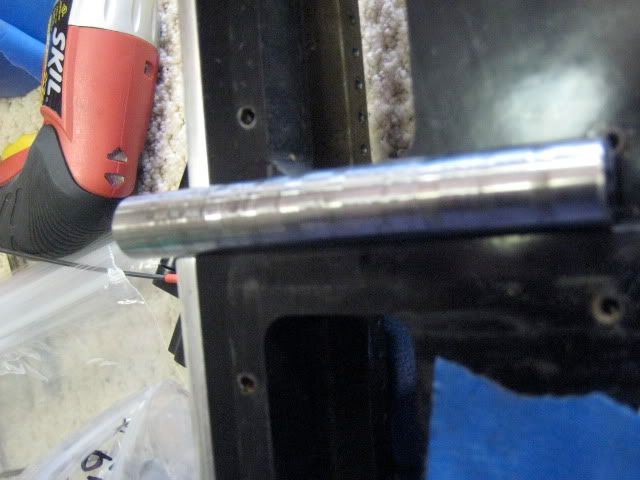

Here's what the axle looked like when I got it apart

I polished the changers and installed new axles....you cannot believe how much better it plays

|

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 3 Oct 2011 6:29 am

Posted 3 Oct 2011 6:29 am |

|

| Thanks Tony. Looks like a lot of wear? Did you use some stainless drill rod or just order new axles from Emmons? Nice job polishing the changer. |

|

|

|

Tony Glassman

From:

The Great Northwest

|

Posted 3 Oct 2011 6:55 am

Posted 3 Oct 2011 6:55 am |

|

Jerry, I used drill rod.

I had my machinist cut and chamfer it to match the OEM. I then re-polished them. [I'm a firm believer in buffing all surfaces where metal surfaces glide or mate (e.g. changer axle, cross shaft ends etc.)]

Polishing the changer is easy too. Mike Cass turned me on to his technique. He takes all the pull fingers, places them on the old axle and clamps them together tight.

Place this assembly in a soft jaw vice, and w/ crocus or 3000 wet paper, sand all 10 changer heads using a two-handed shoeshine rag motion. Doing it en masse insures that all fingers will maintain the same radius.....then polish similarly on a buffing wheel with Tripoli brown followed by white compound.

I didn't do to much to the lower fingers other than a quick buff, as they are not directly involved in either string contact or movement. |

|

|

|

Kevin Hatton

From:

Buffalo, N.Y.

|

Posted 3 Oct 2011 9:34 am

Posted 3 Oct 2011 9:34 am |

|

| There are many used steel guitars out there being bought and sold that need this kind of maintenance. This is visual proof. A 30 year old steel guitar needs maintenance. This is prime example of a job well done resulting in a better playing instrument. Personally, I wouldn't give a decent price for a 30 year old guitar that hasn't been maintenanced. People wonder why these old guitars sometimes do not play accurately. I'm sure Mike Cass sees this all the time. When he does an old guitar it's better than new. |

|

|

|

Jerry Overstreet

From:

Louisville Ky

|

Posted 3 Oct 2011 1:17 pm

Posted 3 Oct 2011 1:17 pm |

|

| Thanks guys. I'm a pretty fair mechanic, but never had one of these completely disassembled. I think maybe I'm up to it though. Thanks for the tips. |

|

|

|

Tony Glassman

From:

The Great Northwest

|

Posted 4 Oct 2011 11:25 pm

Posted 4 Oct 2011 11:25 pm |

|

| Just take a picture and keep all the shims and fingers in proper order when you take it apart, so you can reassemble it the same way. |

|

|

|