| Author |

Topic: Who makes a Half Stop w: ball bearing ? |

CrowBear Schmitt

From:

Ariege, - PairO'knees, - France

|

Posted 30 Dec 2009 9:45 am

Posted 30 Dec 2009 9:45 am |

|

Greetings !

having looked into the different types of half stops,

i would like to know which steel builder offers the ball bearing half stop ?

Mercy bookoo  |

|

|

|

richard burton

From:

Britain

|

Posted 30 Dec 2009 10:09 am

Posted 30 Dec 2009 10:09 am |

|

| I tried it once when I was making steel guitars, but it was too easy to overshoot. |

|

|

|

Bent Romnes

From:

London,Ontario, Canada

|

|

|

|

CrowBear Schmitt

From:

Ariege, - PairO'knees, - France

|

Posted 3 Jan 2010 8:22 am

Posted 3 Jan 2010 8:22 am |

|

|

|

|

|

Bent Romnes

From:

London,Ontario, Canada

|

Posted 3 Jan 2010 8:37 am

Posted 3 Jan 2010 8:37 am |

|

Thanks Crowbear. Simple as that eh?

Richard, with the correct spring pressure, I can't see how it would be any easier to overshoot, especially compared to the conventional one.

_________________

BenRom Pedal Steel Guitars

https://www.facebook.com/groups/212050572323614/ |

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

|

|

|

CrowBear Schmitt

From:

Ariege, - PairO'knees, - France

|

Posted 3 Jan 2010 9:55 am

Posted 3 Jan 2010 9:55 am |

|

i thought the WBS system used a piston

perhaps there's a ball bearing in it as well

Thanx Georg |

|

|

|

Bent Romnes

From:

London,Ontario, Canada

|

Posted 3 Jan 2010 10:38 am

Posted 3 Jan 2010 10:38 am |

|

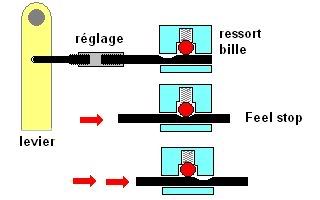

Georg, yes that's it. Definitely a keeper or at least something to work out from. The smart things I see here is first the solid looks of the whole assembly. Then we have the set screw on top that obvious ly adjusts spring pressure to a degreee and thereby get the feel very close to your preference.

I can see experimenting with the shape and depth of the track for the ball in the "piston rod". The steeper the track, the harder the stop. The slacker the track, the softer the stop becomes.

The concerns I would have is the few extra ounces of added weight compared to a conventional half stop.Not only a solid looking block and angle for the stop itself but also an extra push arm on the cross rod. Could be I am splitting hairs but every ounce counts.

_________________

BenRom Pedal Steel Guitars

https://www.facebook.com/groups/212050572323614/ |

|

|

|

Billy McCombs

From:

Bakersfield California, USA

|

Posted 3 Jan 2010 8:39 pm half stop

Posted 3 Jan 2010 8:39 pm half stop |

|

Georg, do you think that half stop would work on a D 10 Emmons L2? Thanks

_________________

78 Emmons PP,Great tone.82 Emmons SKH #56 |

|

|

|

Chris Lucker

From:

Los Angeles, California USA

|

Posted 3 Jan 2010 8:51 pm

Posted 3 Jan 2010 8:51 pm |

|

I used a ball plunger half stop on a Marlen I rebuilt several years ago. I got the plunger part off the shelf from SmallParts.com before there was a dot.com. McMaster probably has them as well. But as Liz Taylor's Husband says above, it is too easy to blow right through the feel stop. It does make you appreciate that you could find the half stop by ear, however.

Read what Jim says below. I remember that problem too. When I fixed it, I made the feel too subtle.

Last edited by Chris Lucker on 3 Jan 2010 9:34 pm; edited 1 time in total |

|

|

|

Jim Palenscar

From:

Oceanside, Calif, USA

|

Posted 3 Jan 2010 9:11 pm

Posted 3 Jan 2010 9:11 pm |

|

| I gave it a go years ago an finally blew it off but still think it could be done. The problem that I ran in to was that it would stick coming back when I had enough pressure on it to feel it solidly so I then made a steeper ramp going than coming (if you get my drift) and that seemed to help some but it still wasn't what I was hoping for so gave up (for the time being). |

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

|

|

|

Bent Romnes

From:

London,Ontario, Canada

|

Posted 4 Jan 2010 6:48 am

Posted 4 Jan 2010 6:48 am |

|

| Chris Lucker wrote: |

| But as Liz Taylor's Husband says above, it is too easy to blow right through the feel stop. |

Chris, I would think that if the builder works with the angle and depth of the ball track, and the spring tension, that this halfstop would work fine

_________________

BenRom Pedal Steel Guitars

https://www.facebook.com/groups/212050572323614/ |

|

|

|

CrowBear Schmitt

From:

Ariege, - PairO'knees, - France

|

Posted 4 Jan 2010 7:52 am

Posted 4 Jan 2010 7:52 am |

|

| aside from WBS, any other builders or lone craftsmen offer any ? |

|

|

|

Billy McCombs

From:

Bakersfield California, USA

|

Posted 4 Jan 2010 1:08 pm

Posted 4 Jan 2010 1:08 pm |

|

Emmons has them for $200.00, Ouch! Im pretty sure that theres no Ball bearings in them.

_________________

78 Emmons PP,Great tone.82 Emmons SKH #56 |

|

|

|

Ross Shafer

From:

Petaluma, California

|

Posted 4 Jan 2010 1:35 pm

Posted 4 Jan 2010 1:35 pm |

|

Happy New Year Y'all!

Has anyone here actually seen the inside of this mechanism from WBS. I like the idea of this thing but am not really sure there's any kind of ball detent action going on. To me it just looks like a spring loaded brass plunger of adjustable length and adjustable spring pre-load (or maybe that's the lever travel adjustment...)

Just from looking at it I'd guess that it functions thusly: The half feel (d on string 2 for instance) is felt when the knee lever block comes in contact with the nylon nutted end of the brass plunger. To get all the way to the C# (we're still talkin' second string)one just pushes thru the added resistance of the spring in this box. I'd guess that the set screw seen at the top of the box in the picture runs in a slot to keep the plunger from turning when making length adjustments on the nylon nutted end and spring (lever travel?) adjustments on the other end.

I certainly could be wrong, and might well be missing something. I don't see why something like this would need a ball detent to serve as a half-feel, when it'd serve the purpose just as well without it. I do like the idea of something like this better than the standard 9th string feel stop used on most steels. To me this is somewhat similar functionally to 11th finger Carter and some other builders use as a feel stop.

I tried emailing Wolfgang at WBS, but the email bounced right back. Maybe some or our Euro pals have actually seen the inside of one of these and can set me straight! |

|

|

|

Bent Romnes

From:

London,Ontario, Canada

|

Posted 4 Jan 2010 4:18 pm

Posted 4 Jan 2010 4:18 pm |

|

Ross, I believe that a brass plunger would wear too quickly. Maybe a st. steel one, sure, but there again it is rubbing on the rod and makes more wear than a ball bearing would. Also a bit more friction in the whole contraption maybe. Just my thoughts, that's all...

_________________

BenRom Pedal Steel Guitars

https://www.facebook.com/groups/212050572323614/ |

|

|

|

Ross Shafer

From:

Petaluma, California

|

Posted 4 Jan 2010 4:31 pm

Posted 4 Jan 2010 4:31 pm |

|

Howdy Bent,

I'm referring to the brass plunger(OK I'll call it a shaft)you see in the WBS picture...the one with the nylon acorn nut on the end that contacts the knee lever block.

I see no need to apply any kind of perpendicular force to the brass shaft. The "feel" happens when the knee lever block comes in contact with the acorn nut you see threaded into the brass shaft.

I could explain this in 10 seconds in person. I often have a hard time understanding written technical descriptions sometimes. You'd for sure want a bearing for what you are talking about. |

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

Posted 4 Jan 2010 4:33 pm

Posted 4 Jan 2010 4:33 pm |

|

I haven't seen the inside/parts of the WBS half stop. I have held a quickly assembled "DouBle Stop" device in my hand when I visited WBS last summer in search of a new PSG.

It has two spring loaded pistons 90° on the slider - from above and below in the picture...

http://www.wbssteelguitars.com/options.html

...to adjust the feel of the half stop. Can't really say if there are balls at the end of those pistons - I didn't ask or at least can't remember, but it was quite easy to feel the notch half way even on the unfinished device Wolfgang showed me.

As for most steel builders, Wolfgang does keep on improving and fine-tuning everything that goes into the PSGs he build, so details may change slightly over time. |

|

|

|

Ross Shafer

From:

Petaluma, California

|

Posted 4 Jan 2010 4:41 pm

Posted 4 Jan 2010 4:41 pm |

|

Thanks Georg, I stand corrected. I still don't understand the need since the knee lever block doesn't appear to contact the nylon acorn nut until it is part way into its travel....and once it does make contact the "feel" is felt.

Hey, but what do I know! |

|

|

|

Bent Romnes

From:

London,Ontario, Canada

|

Posted 4 Jan 2010 4:49 pm

Posted 4 Jan 2010 4:49 pm |

|

Ross, I get ya. Looking at the WBS one, sure the crossrod pusher goes to the acorn nut on the end of the plunger. There's your first lower. Then the rod gets depressed and stops against the adjusting or tuning nut/screw. There's your second lower.

But looking at Crowbear's sketch, there the pusher should be touching the acorn nut all the time. Then, when the ball drops into the notch, it makes the first stop. Then the rod pushes past the ball and stops against the tuning screw and there's the 2nd lower.

So looking at it this way, the sketch and the WBS are two really different ideas. But then, what is the hole on top with an obvious set screw for on the WBS? Some pressure regulating thing the way I see it.

_________________

BenRom Pedal Steel Guitars

https://www.facebook.com/groups/212050572323614/ |

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

Posted 4 Jan 2010 5:03 pm

Posted 4 Jan 2010 5:03 pm |

|

Ross, I guess the advantage of the DouBle Stop is that you only feel increased resistance when pushing out of the half stop notch - when you've hit the half stop note, and not before or beyond.

Some may find this "point stop" better than a regular spring-loaded half stop, and others may not. Myself I'm not sure, as hitting any half stop dead accurate while playing is difficult and from what I could figure out a well-tuned WBS "DouBle Stop" makes it less difficult but doesn't eliminate the problem. |

|

|

|

Jim Palenscar

From:

Oceanside, Calif, USA

|

Posted 4 Jan 2010 5:16 pm

Posted 4 Jan 2010 5:16 pm |

|

| The half-stop on the Anapeg is the best that I've ever felt. I've tried to duplicate it and have yet to succeed. While it is a spring-based design the difference in the Anapeg is that every part of it is precision fit to reduce the margin for error. The spring is encased in a tube as well as having an insert so that it cannot bend in any direction other than compress. Also the bushings in the bellcranks that it connects to have zero slop and the rods used are all very short and supported in bushings where the length might allow for any flex. One other feature is that the stops are "pulled against" as opposed to being "pushed into" making for a very positive feel to the player. |

|

|

|

Ross Shafer

From:

Petaluma, California

|

Posted 4 Jan 2010 5:18 pm

Posted 4 Jan 2010 5:18 pm |

|

now you're getting me Bent....and I can't think of any reason why what I'm describing wouldn't work. According to George, I'm wrong about the WBS design and it does indeed use some sort of perpendicular plungers.

I described what I thought the screw in the top would be for in my first description...if it were a set screw protruding into a slot on the brass shaft it would allow one to make adjustments on the ends while keeping the shaft from turning.

Since the WBS system doesn't work as I thought...did I just invent a new way to do it? ....very doubtful.... |

|

|

|

Tony Glassman

From:

The Great Northwest

|

Posted 4 Jan 2010 6:47 pm

Posted 4 Jan 2010 6:47 pm |

|

Looking at CrowBear's illustration and comparing it to the WBS picture: the setscrew on top of the WBS mechanism would allow you to increase or decrease the downward pressure of the spring against the ball bearing.

If you assume that the ball-bearing is sitting in the horizontal plunger groove at rest, then tightening (or loosening) the vertical setscrew would increase (or decrease) the effort needed to push the groove horizontally past the ball. Thus, the adjustable 1/2 step feel.

I'm just not sure how you tune the point at which it "kicks-in" (e.g. D#-->D) |

|

|

|